Method for making corrugated base paper by rice straw unbleach pulp

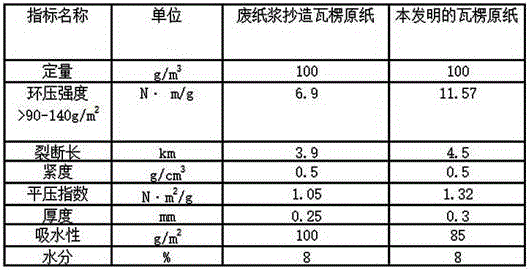

A technology for corrugated base paper and uncolored pulp, which is applied in pulp beating methods, papermaking, textiles and papermaking, etc., can solve problems such as the influence of wood fiber sources, and achieve the effects of large aspect ratio, high pulping efficiency and good fiber quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Cut the rice stalks of the whole plant into 30-40mm long material sections with a grass cutter (manufacturer: Zhangqiu Tony Machinery Manufacturing Co., Ltd. Model: QC50), and then use a cylindrical sieve (manufacturer: Zhangqiu Tony Machinery Manufacture Limited Model YTS800:) Remove impurities and fines for later use.

[0026] 2. Send the prepared raw materials (material section) to the steaming warehouse (manufacturer: model: ) with a belt conveyor (manufacturer: Dandong Aomei Light Industry Machinery Co., Ltd. Model: S650) for pre-steaming (atmospheric pressure, time 1 -10min), and then transported to the continuous steamer (manufacturer: Tianjin Zhongqing Machinery Co., Ltd. model: FD150) through the material plug screw (manufacturer: Dandong Aomei Light Industry Machinery Co., Ltd. model: QZC25) for continuous cooking. During the cooking process, press Add 1.5-2% potassium hydroxide, 1.2-1.5% ammonium sulfite and 1.2-1.5% sodium tripolyphosphate by weight in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com