Gas sensor comprehensive tester and measurement method thereof

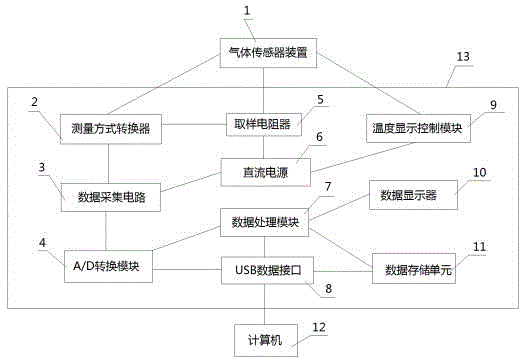

A technology of gas sensor and comprehensive tester, which can be used in measurement devices, instruments, scientific instruments, etc., and can solve the problems of complex gas sensor test systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

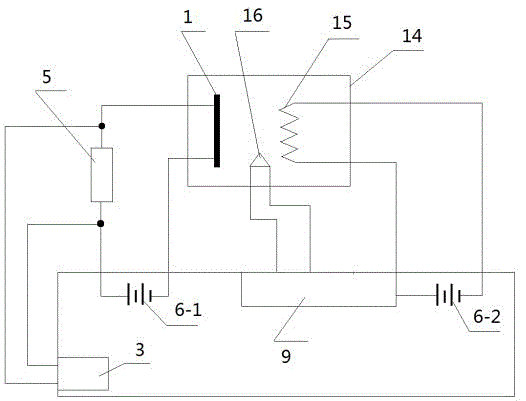

[0024] In this embodiment, the gas sensor comprehensive tester works independently and is not connected with an external computer. Use resistive semiconductor hydrogen sulfide sensor as test object, to gather the given resistance R of described sampling resistor 5 s The output voltage signal V at both ends s way to measure.

[0025] This example figure 2 As shown, the measurement method needs to be supplied with a working voltage V by the adjustable DC working power supply 6-1 in the DC power supply 6. c , according to the principle of resistance voltage division, the internal resistance R of the sensor and the output voltage V at both ends of the sampling resistance s There are the following relations:

[0026] R=(V c -V s ) R s / V s (1)

[0027] The response of the hydrogen sulfide sensor to hydrogen sulfide gas is defined as

[0028] S=V sH2S / V sair (2)

[0029] In the formula, S is the response of hydrogen sulfide sensor to hydrogen sulfide gas, V sair is t...

Embodiment 2

[0046] In this embodiment, the gas sensor comprehensive tester works in cooperation with an external computer, uses a resistive semiconductor ammonia sensor as a test object, and collects characteristic data of the ammonia sensor by directly measuring the internal resistance of the gas sensor.

[0047] In this embodiment, the response of the ammonia sensor to ammonia is defined as

[0048] S=R air / R NH3 (3)

[0049] In the formula, S is the response of the ammonia sensor to ammonia, R air is the internal resistance of the sensor in air, R NH3 is the internal resistance of the sensor in ammonia gas.

[0050] The specific method and operation steps of this embodiment are as follows.

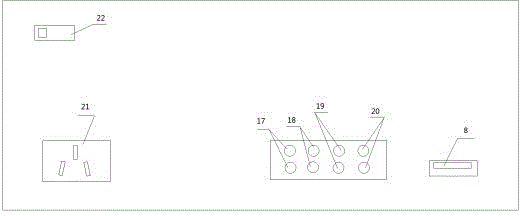

[0051] 1. Install the ammonia sensor 1 to be tested in the sensor device in the test chamber, close the test chamber, and connect the gas distribution system.

[0052] 2. Press image 3 As shown, an external computer is connected to the gas sensor comprehensive tester through a USB interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com