Double-waveband composite broadband wave absorbing material based on frequency selective surface

A frequency-selective surface and wave-absorbing material technology, applied to electrical components, magnetic/electric field shielding, antennas, etc., can solve problems such as insufficient bandwidth, achieve widened bandwidth, enhanced wave-absorbing effect, and good wave-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

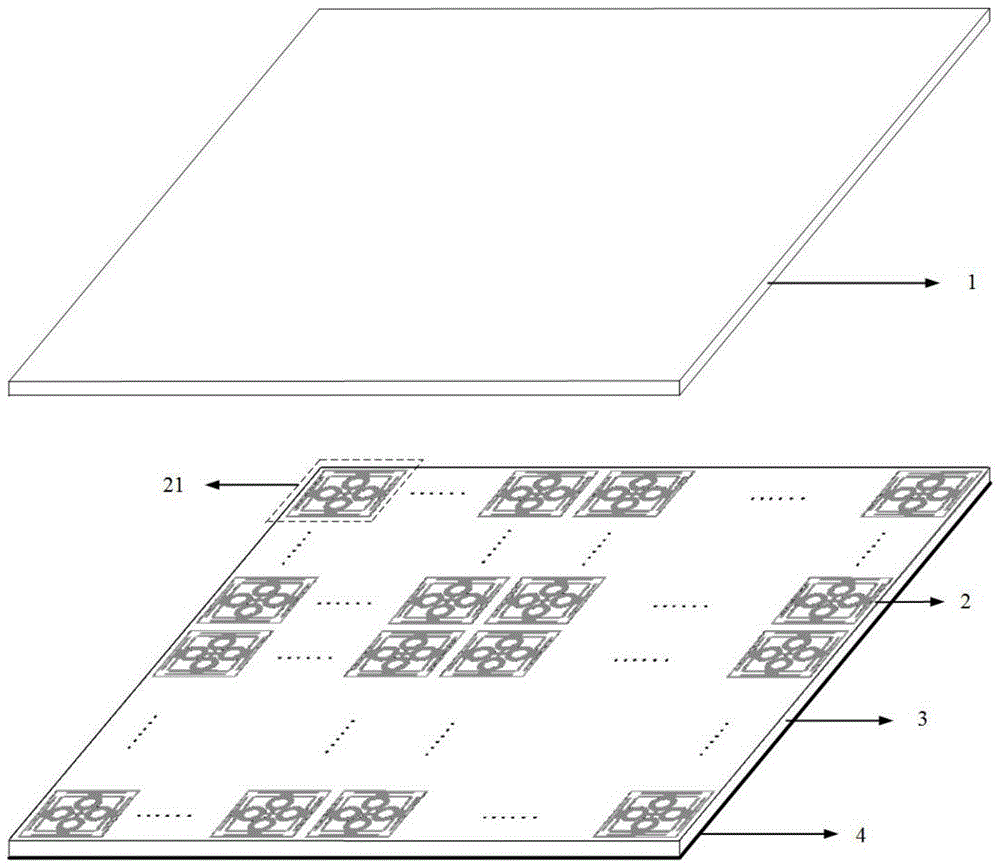

[0023] refer to figure 1 , a dual-band composite broadband absorbing material based on a frequency selective surface, including a base material layer 1, a frequency selective surface 2, a dielectric plate 3 and a floor 4; the base material layer 1 is a rectangular plate of 31.5mm×31.5mm×1.2mm, Its relative permittivity ε'=20.30, relative permeability μ'=3.55, electric loss tangent tanδ D =0.2266, magnetic loss tangent tanδ M =0.4422; the frequency selective surface 2 is a square array formed by 21 periodic arrangements of 7×7 passive resonant units, and the array period is 4.5mm; the dielectric plate 3 is a 31.5mm×31.5mm×1.3mm FR4 rectangular plate; the frequency The selection surface 2 and the floor 4 are printed on the upper and lower surfaces of the dielectric board 3 respectively, and the matrix material layer 1 is glued to the upper surface of the frequency selection surface.

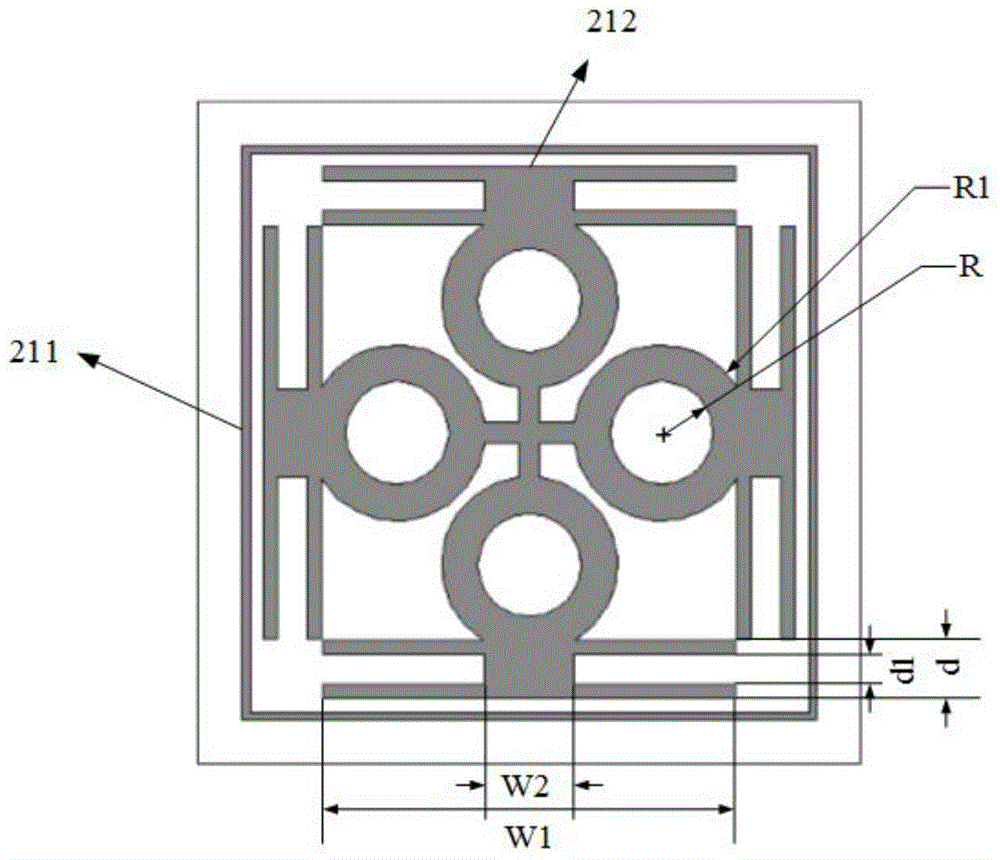

[0024] refer to figure 2 , the passive resonant unit 21 is composed of a square ring patch ...

Embodiment 2

[0025] The structure of embodiment 2 is identical with the structure of embodiment 1, and following parameter has been adjusted:

[0026] The inner diameter R of the four rings in the deformed Jerusalem cross-shaped patch 212 is 0.3 mm, and the outer diameter R1 is 0.6 mm; the arrangement period of the passive resonant unit 21 is 4.4 mm; the base material layer 1 is 30.8 mm×30.8 mm× 1.1mm rectangular plate, its relative permittivity ε'=18.50, relative permeability μ'=3.70, electric loss tangent tanδ D =0.23, magnetic loss tangent tanδ M =0.45; the size of the dielectric board 3 is 30.8mm×30.8mm×1.2mm.

Embodiment 3

[0027] The structure of embodiment 3 is identical with the structure of embodiment 1, and following parameter has been adjusted:

[0028] The inner diameter R of the four rings in the deformed Jerusalem cross-shaped patch 212 is R=0.5mm, and the outer diameter R1=0.8mm; the arrangement period of the passive resonant unit 21 is 4.6mm; the base material layer 1 is 32.2mm×32.2mm× 1.3mm rectangular plate, its relative permittivity ε'=22.00, relative permeability μ'=4.00, electric loss tangent tanδ D =0.25, magnetic loss tangent tanδ M =0.30; the size of the dielectric board 3 is 32.2mm×32.2mm×1.1mm.

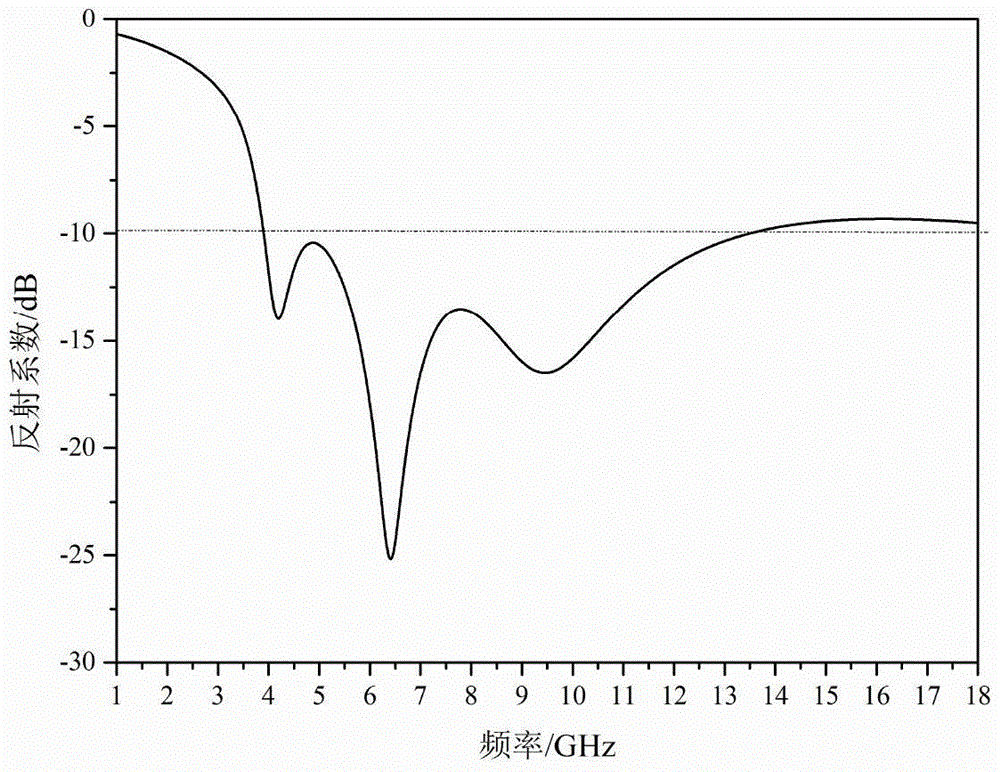

[0029] Effect of the present invention can be further illustrated in conjunction with the following simulation results:

[0030] 1. Simulation content

[0031] 1.1 Utilize commercial emulation software HFSS_13.0 to the S of above-mentioned embodiment 1 11 The parameters are simulated and calculated, and the results are as follows image 3 shown.

[0032] 1.2 Utilize the commercia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com