Double-grid electrode for high-beam-quality large-power VCSEL (Vertical Cavity Surface Emitting Laser) same-phase coupling array

A grid electrode, coupled array technology, applied in circuits, lasers, electrical components, etc., can solve problems such as uneven current expansion, achieve high optical power, and improve beam quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

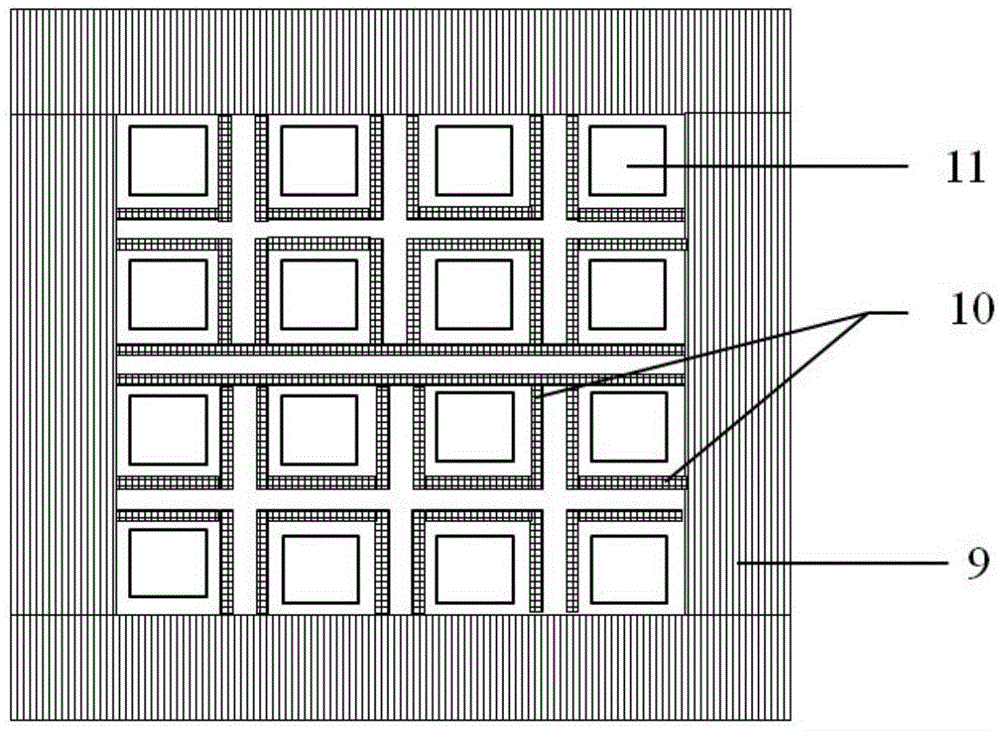

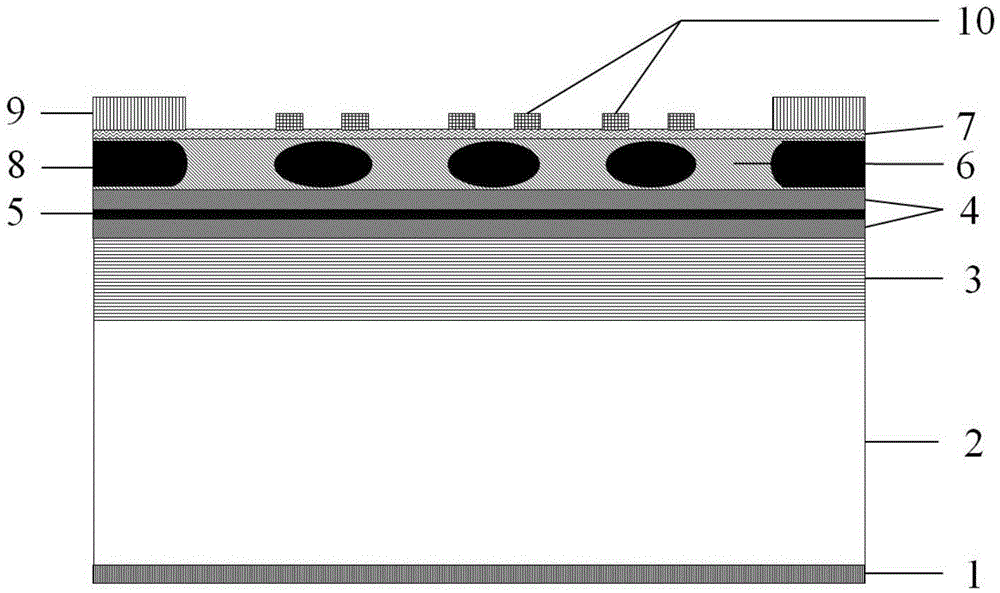

[0028] Combine below Figure 4-Figure 12 The specific implementation methods of high-beam quality and high-power VCSEL in-phase coupling array and double grid electrodes are introduced respectively;

[0029] Step 1. Using metal-organic chemical vapor deposition (MOCVD) to sequentially epitaxially grow thirty-four pairs of n-Al on N-GaAs (0.12-0.9) GaAs and n-Al 0.9 GaAs forms the DBR mirror, Al (0.12-0.9) GaAs / Al 0.9 GaAs lower confinement layer, three pairs of Al 0.3 GaAs / GaAs quantum well structure active region, Al 0.9 GaAs / Al (0.12-0.9) GaAs upper confinement layer, 22.5 to p-Al 0.12 GaAs and p-Al (0.9-0.12) GaAs forms the DBR mirror, p-Al 0.12 GaAs and p-GaAs heavily doped contact layers;

[0030] Step 2, using plasma-enhanced chemical vapor deposition (PECVD) to grow a layer of 3 μm silicon dioxide on the surface of the epitaxial wafer obtained above;

[0031] Step 3. Use reverse glue to do photolithography and sputtering process to sputter a layer of silicon d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com