Processing method and device for polarization-maintaining optical fiber pigtail in non-melting point optical fiber gyroscope

A fiber optic gyroscope and polarization-maintaining optical fiber technology, applied in the field of optical fiber pigtail processing, can solve the problems of difficult control of axis positioning accuracy, low efficiency of axis positioning, poor consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

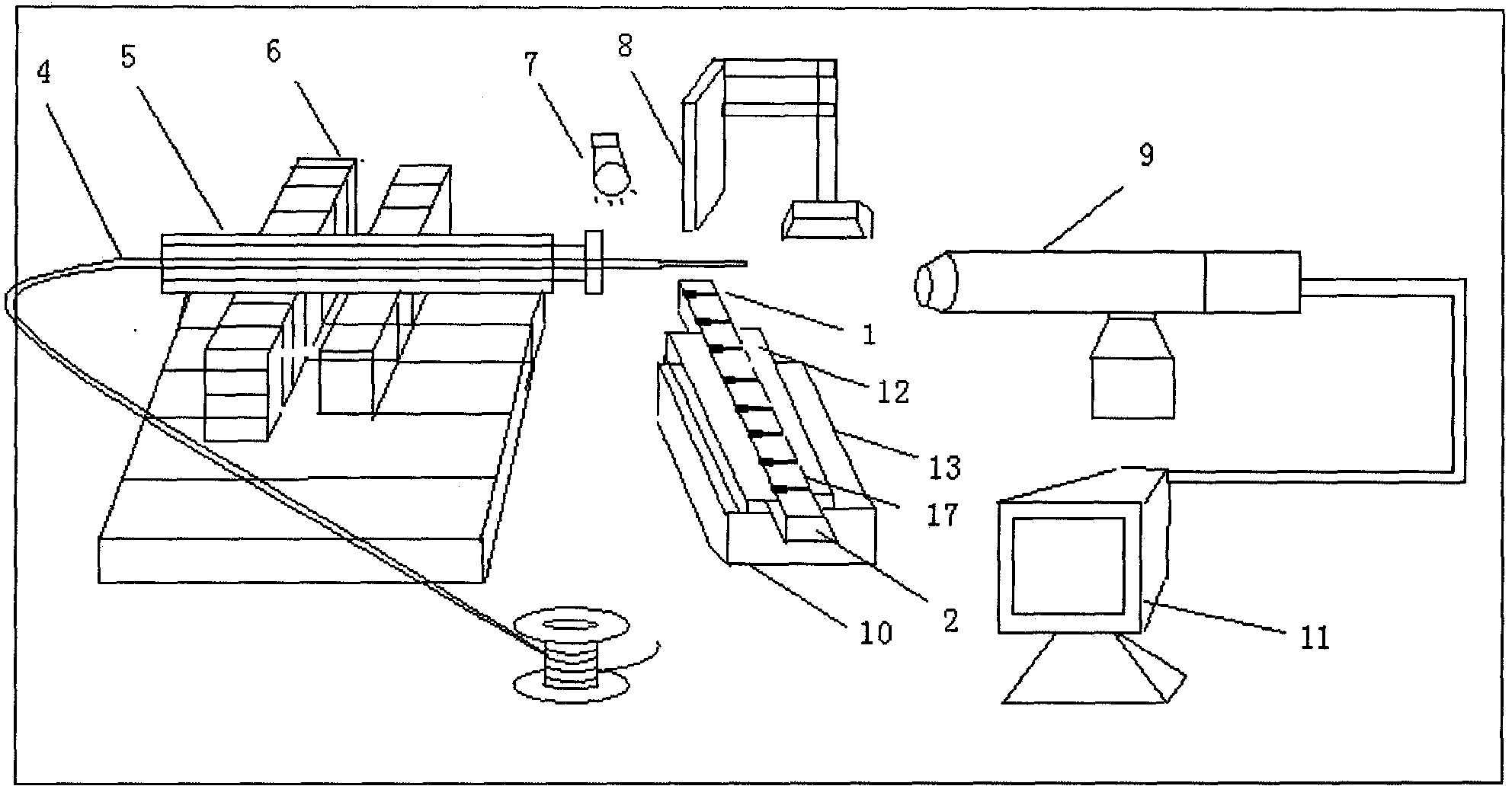

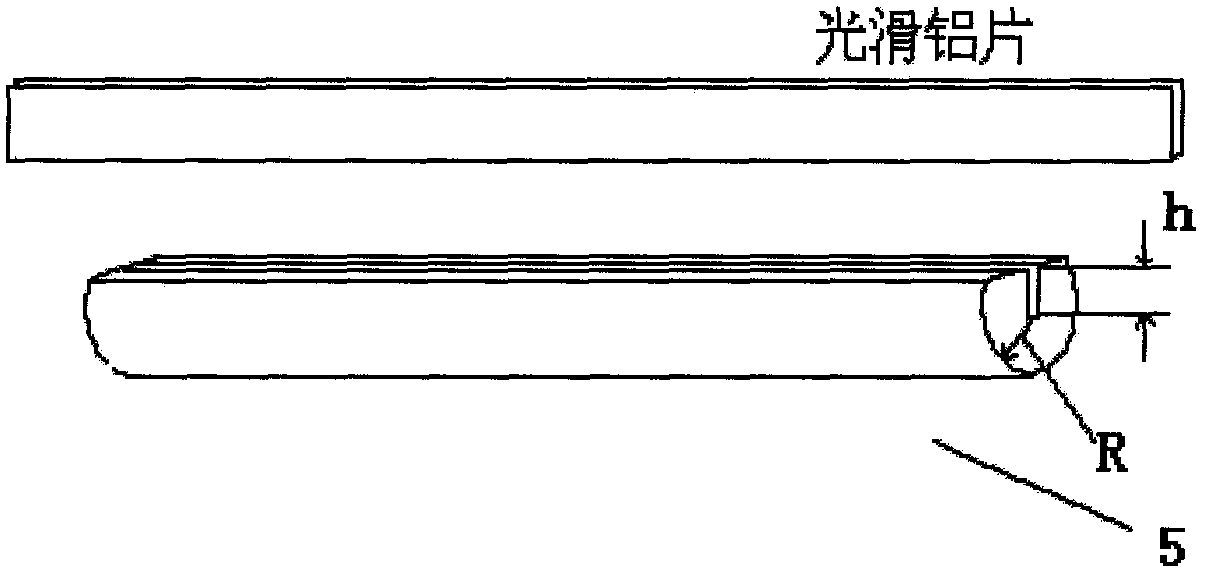

[0072] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

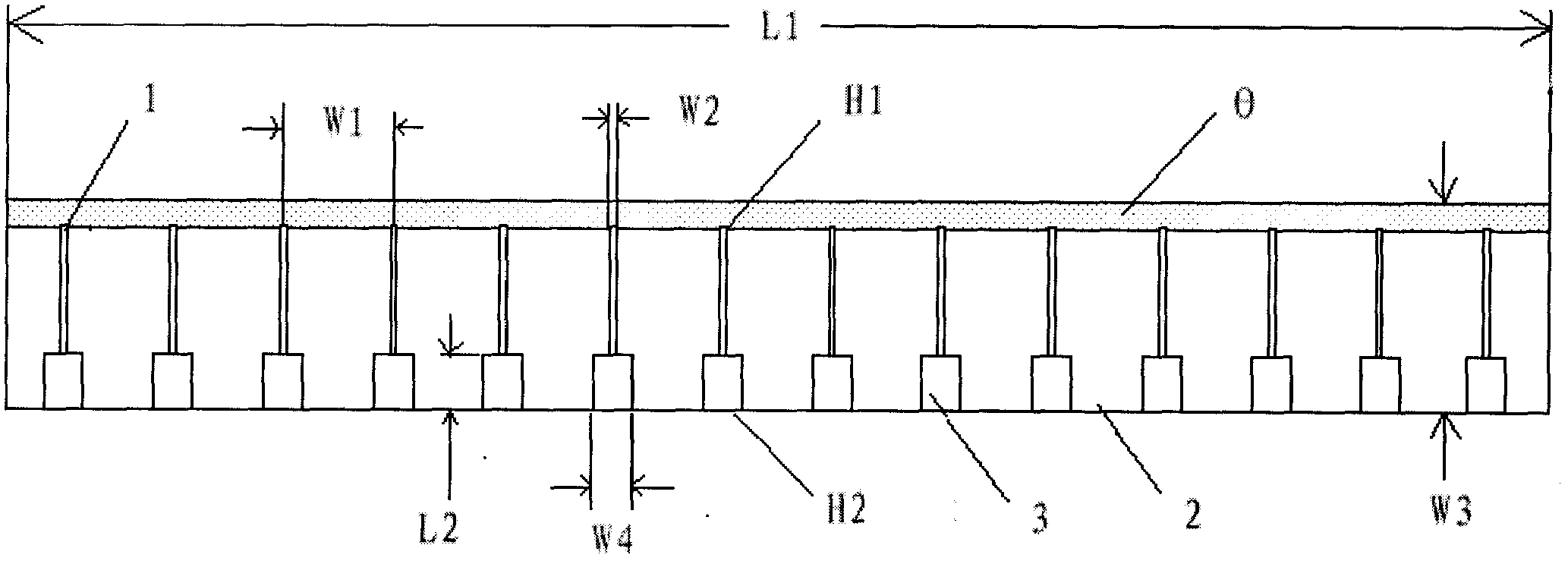

[0073] Such as figure 1 Shown is a schematic diagram of the structure of the fiber fixing block array of the present invention. It can be seen from the figure that the fiber fixing block array 2 is provided with a plurality of parallel grooves 1 and a plurality of boring grooves 3 connected with the grooves 1, wherein the end faces of the fiber fixing block array 2 are inclined The angle of the angle is 15°, and the preparation method of the optical fiber fixing block array 2 is as follows:

[0074] (1) Select LiNbO with a diameter of 3 inches 3 The wafer is scribed in the Y direction to form groove 1, the scribed groove index W1=2.5 mm, the groove width W2=135 microns, the groove depth H1=70 microns, after scribing, the wafer is rotated 90°, and then divided according to W3= 4.5 mm for cutting, when the wafer is completely diced, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com