Bacterium-reducing method for dehydrated garlic products

The technology of a product and garlic slices is applied in the field of bacteria reduction of dehydrated garlic products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Use the dehydrated garlic flakes whose total number of bacterial colonies exceeds the standard value of 0.5-1lgcfu / g after processing as raw material, and carry out ozone reduction process treatment:

[0022] Place the dehydrated garlic slices in a closed space, and continuously inject ozone, so that when the ozone concentration in the space reaches 20mg / m3, start timing, and when the processing time reaches 30min, take out the samples and pack the processed samples. The total number of colonies of dehydrated garlic slices can be reduced by about 1 lgcfu / g, and there is no significant difference in color, protein content, and rehydration ratio. Although allicin has slightly decreased, the change is small.

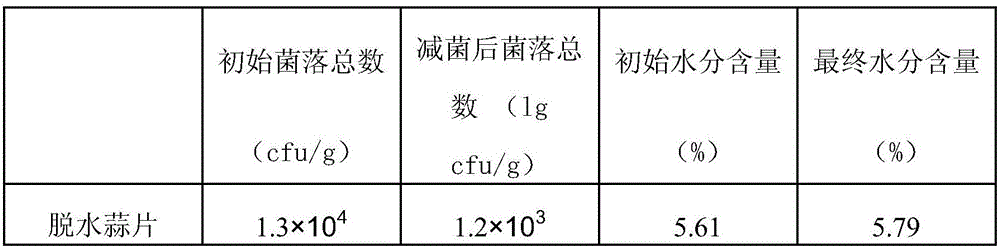

[0023] Table 1 Ozone reduction of bacteria in dehydrated garlic slices

[0024]

Embodiment 2

[0026] After the processing is completed, the total number of detected bacterial colonies exceeds the standard, but the dehydrated garlic slices exceeding the standard by 1-2 lg (cfu / g) are used as raw materials for ozone reduction process treatment:

[0027] First place the dehydrated garlic slices in a closed space, continuously inject ozone, and measure the ozone concentration. When the ozone concentration in the space reaches 40mg / m 3 When the time is up to 90 minutes, the total number of colonies in dehydrated garlic slices can be reduced by about 1.5-2 lgcfu / g. There is no significant difference in color, protein content, and rehydration ratio. decreased, but the change was small.

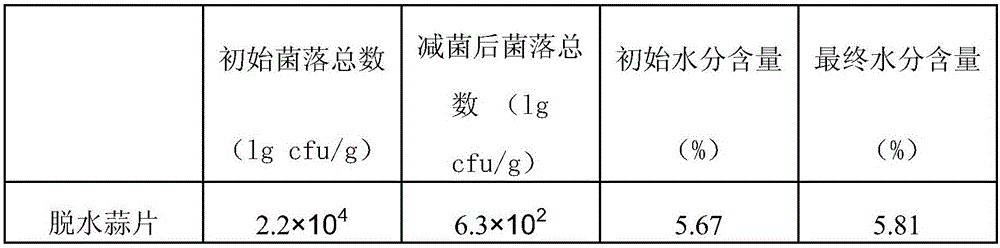

[0028] Table 2 Ozone reduction of dehydrated garlic slices

[0029]

Embodiment 3

[0031] After processing, the dehydrated garlic slices whose total number of colonies exceeds the standard to 2-3 lgcfu / g are used as raw materials, and the ozone combined with superheated steam is used to reduce bacteria:

[0032] First place the sample in a closed space, inject ozone so that the ozone concentration in the space reaches 40mg / m3, start timing, and when the treatment time reaches 30min, treat it with superheated steam at 115°C for 1min, and then send it to an oven for 1h at 60°C. The total number of colonies in dehydrated garlic slices can be reduced by about 2-3 lgcfu / g, the color changes slightly, and the protein content and rehydration ratio have no significant changes. Although allicin has decreased, the change is small.

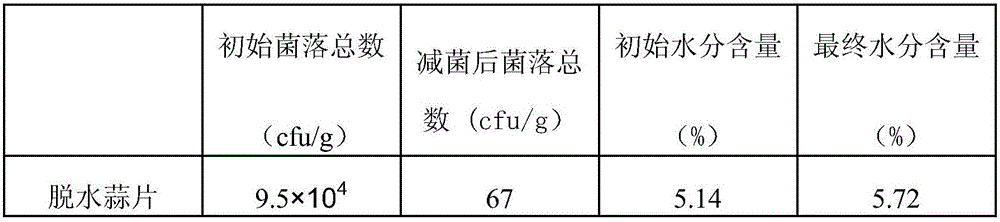

[0033] Table 3 Bacteria reduction of dehydrated garlic slices by ozone combined with superheated steam

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com