Intelligent environment-friendly paper diaper for baby

An environmentally friendly paper and diaper technology, applied in the field of sanitary products, can solve problems such as uneconomical, poor air permeability, and unenvironmental protection, and achieve the effect of preventing the loss of the baby

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

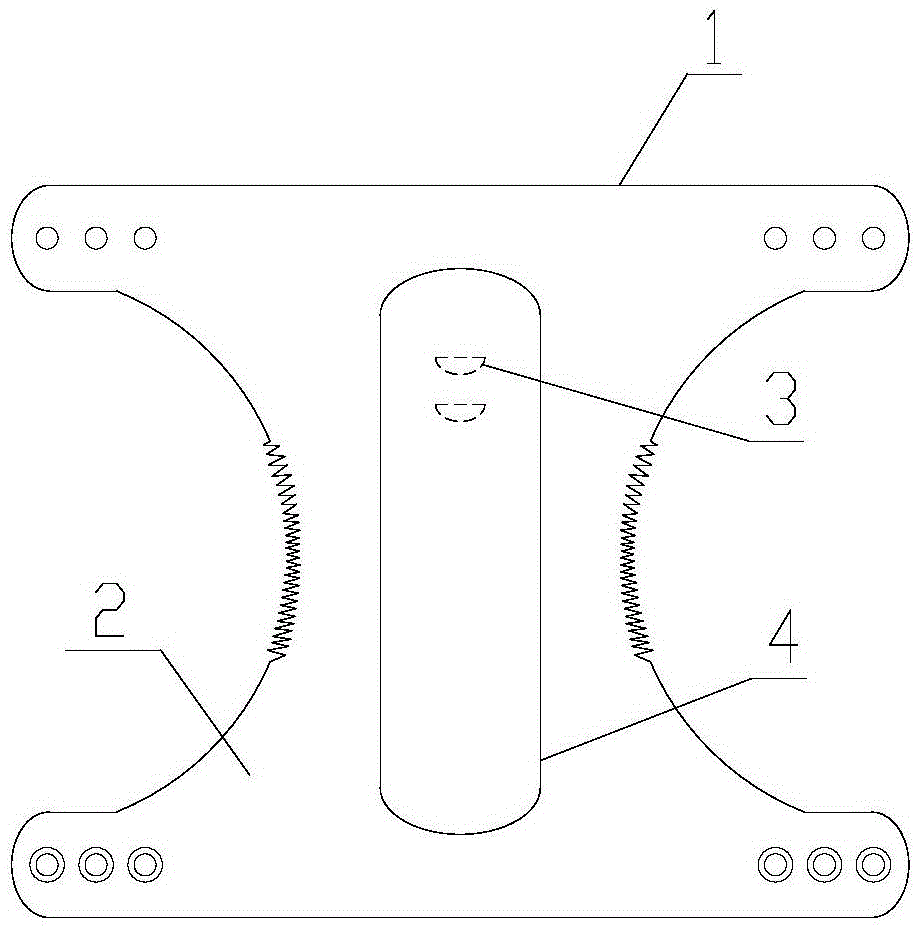

[0033] Such as figure 1 As shown, the smart environmentally friendly diapers for babies are composed of diapers 1, a diaper 4 and a smart pee button. Among them, the changing pad 4 is located in the middle of the inner layer 2 of the diaper and can be removed; the superfine denier fiber absorbent flannel is provided with two pockets 3, which are used to place the smart pee button according to the baby's urine position. The Hush button is connected to the mobile phone via Bluetooth.

[0034] The diaper includes an inner layer and an outer layer. The inner layer is made of a blend of 45wt% corn fiber and 55wt% bamboo fiber, and the outer layer is a chemical fiber woven fabric coated with TPU;

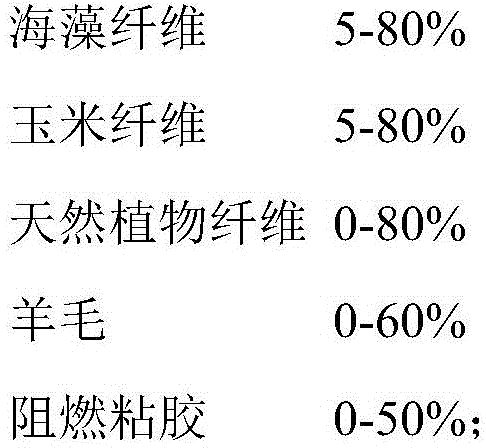

[0035] The changing pad is composed of a surface layer and an inner core. The surface layer fabric is a non-woven fabric, which is made of the following mass percentage of raw materials:

[0036] Seaweed fiber 5%

[0037] Corn fiber 60%

[0038] Bamboo fiber 35%;

[0039] The inner core of the ch...

Embodiment 2

[0047] The intelligent environmental protection diapers for babies described in this embodiment are the same as in embodiment 1, except that the non-woven fabric is made of the following mass percentage raw materials:

[0048] Seaweed fiber 7%

[0049] Corn fiber 70%

[0050] Modal fiber 23%

[0051] The preparation process of non-woven fabric adopts spunlace, and the steps are as follows:

[0052] Fiber raw materials—opening—mixing—carding—web forming—stacking—pre-wetting—positive and negative spunlace—finishing—drying—winding—flame retardant environmentally friendly non-woven fabric.

[0053] Among them, the spunlace distance of the front and back spunlace is 38mm, and the spunlace pressure is 104×10 5 Pa; the mixing time is 50min, the rotating speed of the rocker arm is 40r / min when mixing; the cylinder rotating speed is 350r / min when forming the net, the number of chopper swings is 650 times / min, and the finishing temperature is 120℃.

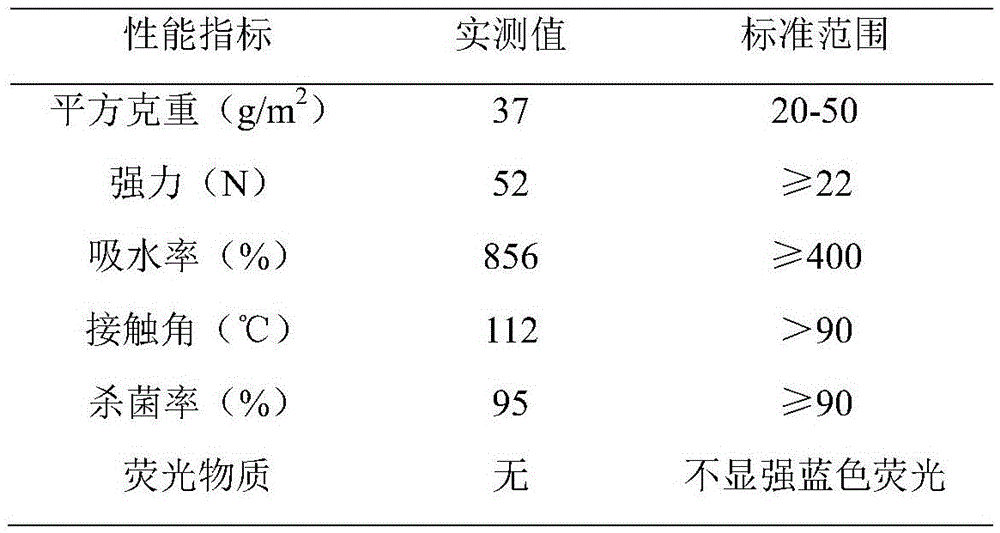

[0054] According to the national standard GB / T26...

Embodiment 3

[0058] The intelligent environmental protection diapers for babies described in this embodiment are the same as in embodiment 1, except that the non-woven fabric is made of the following mass percentage raw materials:

[0059] Seaweed fiber 9%

[0060] Corn fiber 80%

[0061] Tencel 11%

[0062] The preparation process of non-woven fabric adopts spunlace, and the steps are as follows:

[0063] Fiber raw materials—opening—mixing—carding—web forming—stacking—pre-wetting—positive and negative spunlace—finishing—drying—winding—flame retardant environmentally friendly non-woven fabric.

[0064] Among them, the spunlace distance of the front and back spunlace is 39mm, and the spunlace pressure is 110×10 5 Pa; the mixing time is 50min, the rotating speed of the rocker arm is 40r / min when mixing; the cylinder rotating speed is 350r / min when forming the net, the number of chopper swings is 650 times / min, and the finishing temperature is 120℃.

[0065] According to the national standard GB / T26379-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com