Probiotics solid beverage containing mushroom polysaccharides

A technology for solid beverages and probiotics, which is applied in the direction of oligosaccharide-containing food ingredients, the function and application of food ingredients, etc., to achieve the effects of enhancing immunity, improving colonization rate and good tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

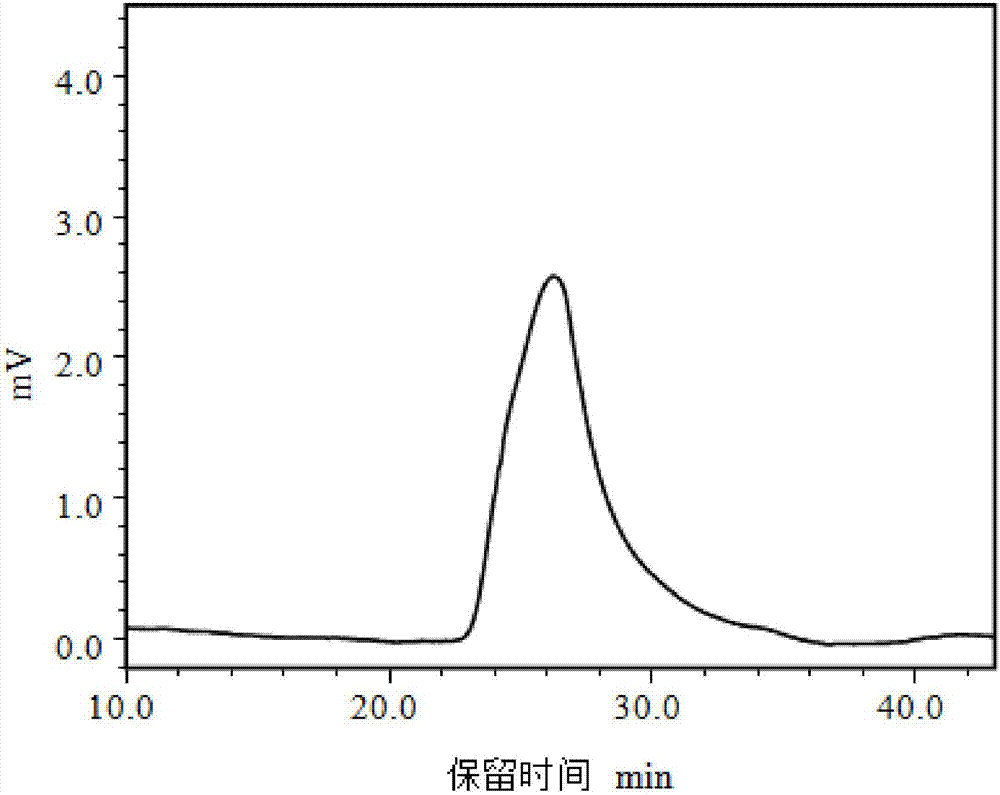

Image

Examples

Embodiment 1

[0038] ① Mixing materials: according to the weight percentage of each component, pleurotus eryngii polysaccharide 4.5%, tremella polysaccharide 4.8%, galacto-oligosaccharide 10%, fructo-oligosaccharide 8.5%, water-soluble dietary fiber 68.1%, sucralose 0.1%, fully well mixed;

[0039] ②Granulation: Add 85% ethanol to 10% by weight of the uniformly mixed material to make a soft material. After adding to the soft material, pass through a 26-mesh sieve to make granules;

[0040] ③Drying: Put the prepared granules into a flat plate, push them into a blast drying oven for drying, the drying temperature is 50-65°C, turn on the blast, and take out the granules when they are dried to a moisture content of 3.7%.

[0041] ④ Grain sizing: pass the taken out granules through a 26-mesh sieve again to obtain solid granules;

[0042] ⑤ Mixing: Cool the sized solid particles to room temperature, and mix them evenly with 4.0% probiotic powder in a 100,000-class clean environment.

[0043] ⑥P...

Embodiment 2

[0045]① Mixing materials: according to the weight percentage of each component, pleurotus eryngii polysaccharide 3.0%, tremella polysaccharide 5.0%, galacto-oligosaccharide 15%, fructo-oligosaccharide 5.0%, water-soluble dietary fiber 65.95%, sucralose 0.05%, fully well mixed;

[0046] ②Granulation: Add 85% ethanol to 15% by weight of the uniformly mixed material to make soft material. After adding to the soft material, pass through a 26-mesh sieve to make granules;

[0047] ③Drying: Put the prepared granules into a flat plate, push them into a blast drying oven for drying, the drying temperature is 50-65°C, turn on the blast, and take out the granules when they are dried to a moisture content of 3.5%.

[0048] ④ Grain sizing: pass the taken out granules through a 26-mesh sieve again to obtain solid granules;

[0049] ⑤ Mixing: Cool the sized solid particles to room temperature, and mix them evenly with 6.0% probiotic powder in a 100,000-class clean environment.

[0050] ⑥Pa...

Embodiment 3

[0052] ① Mixing materials: according to the weight percentage of each component, pleurotus eryngii polysaccharide 3.3%, tremella polysaccharide 4.7%, galacto-oligosaccharide 13.3%, fructo-oligosaccharide 6.7%, water-soluble dietary fiber 66.6%, sucralose 0.07%, fully well mixed;

[0053] ②Granulation: Add 85% ethanol to the uniformly mixed material according to the weight percentage of 12 to make soft material. After adding to the soft material, pass through a 26 mesh sieve to make granules;

[0054] ③Drying: Put the prepared granules into a flat plate, push them into a blast drying oven for drying, the drying temperature is 50-65°C, turn on the blast, and take out the granules when they are dried to a moisture content of 3.7%.

[0055] ④ Grain sizing: pass the taken out granules through a 26-mesh sieve again to obtain solid granules;

[0056] ⑤ Mixing: Cool the sized solid particles to room temperature, and mix them evenly with 5.33% probiotic powder in a 100,000-class clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com