Microecological preparation for livestock and preparation method of microecological preparation for livestock

A technology of probiotics and additives, applied in the field of microorganisms, can solve the problems of limiting the wide application of probiotics, instability of gastric acid and bile salts, difficulty in meeting treatment needs, etc., to improve feed conversion rate, colonization rate, and The effect of immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

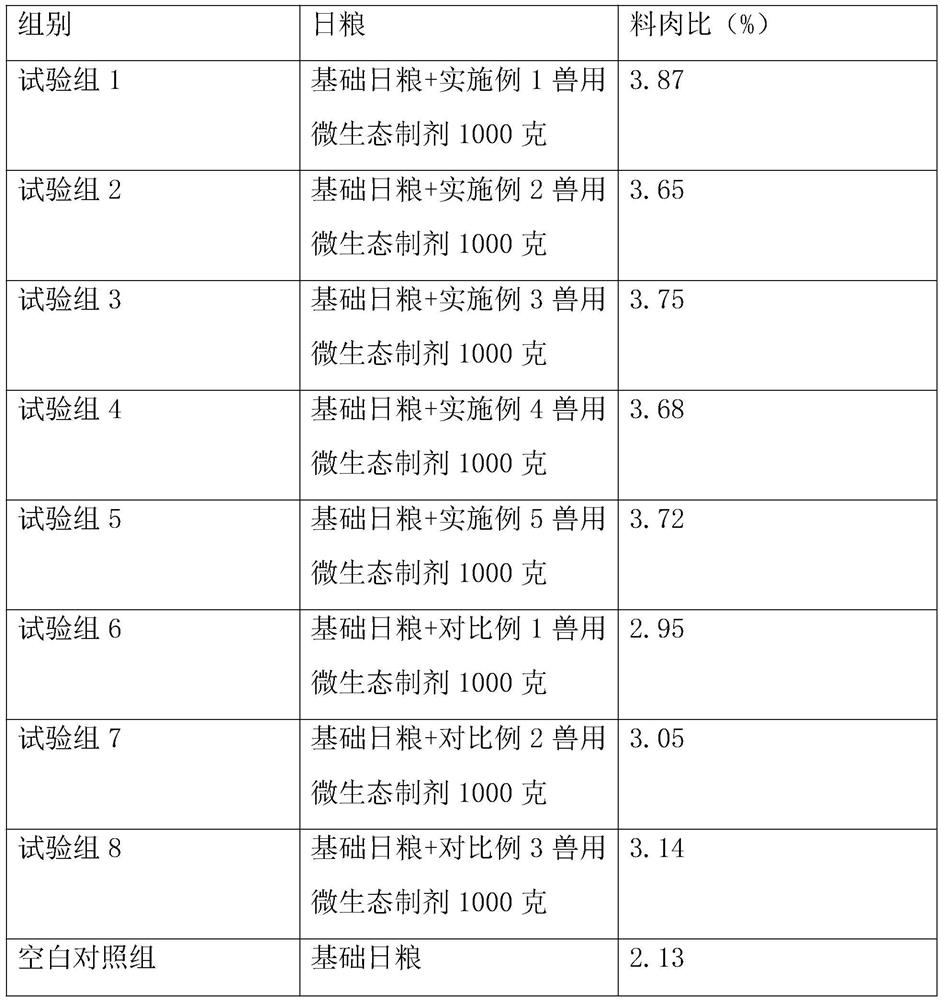

Examples

Embodiment 1

[0029] (1) Weigh 3 grams of soybean meal powder, 4 grams of corn flour, 3 grams of yeast powder, 0.2 grams of potassium dihydrogen phosphate, 0.3 grams of magnesium sulfate heptahydrate, 0.5 grams of calcium carbonate, and 2 grams of sodium acetate to obtain a fermentation additive. Clostridium butyricum is prepared into 4% Clostridium butyricum bacterium liquid with sterile water, measure 4ml of Clostridium butyricum bacterium liquid and inoculate into 3 grams of fermentation additive, statically under the condition of passing carbon dioxide or nitrogen at 37°C Put 20 days and carry out anaerobic fermentation, obtain Clostridium butyricum fermentation product;

[0030] (2) Take Enterococcus faecalis and be mixed with sterile water to be 4% Enterococcus faecalis bacterium liquid, measure 4ml Enterococcus faecalis bacterium liquid and inoculate in 3 grams of fermentation additives, aerobic at 37 ℃ in fermenter Ferment for 10 days to obtain the Enterococcus faecalis fermentation...

Embodiment 2

[0034] (1) Weigh 2 grams of soybean meal powder, 1 gram of corn flour, 1 gram of yeast powder, 0.1 gram of potassium dihydrogen phosphate, 0.1 gram of magnesium sulfate heptahydrate, 0.1 gram of calcium carbonate, and 1 gram of sodium acetate to obtain a fermentation additive. Clostridium butyricum is prepared into a 3% Clostridium butyricum liquid with sterile water, and 3ml of the Clostridium butyricum liquid is inoculated into 1 gram of the fermentation additive, and the clostridium butyricum bacterium is inoculated at 35°C under the condition of carbon dioxide or nitrogen. Put 15 days and carry out anaerobic fermentation, obtain Clostridium butyricum fermentation product;

[0035] (2) Take Enterococcus faecalis and mix it with sterile water to make a 3% Enterococcus faecalis bacterium liquid, measure 3ml Enterococcus faecalis bacterium liquid and inoculate it into 1 gram of fermentation additive, aerobic at 35°C in a fermenter Ferment for 7 days to obtain the Enterococcus ...

Embodiment 3

[0039] (1) Weigh 5 grams of soybean meal powder, 6 grams of corn flour, 5 grams of yeast powder, 0.5 grams of potassium dihydrogen phosphate, 0.5 grams of magnesium sulfate heptahydrate, 1 gram of calcium carbonate, and 3 grams of sodium acetate to obtain a fermentation additive. Clostridium butyricum is prepared into 5% Clostridium butyricum bacteria liquid with sterile water, and 5ml of Clostridium butyricum bacteria liquid is inoculated into 4 grams of fermentation additives, statically at 38°C under the condition of carbon dioxide or nitrogen. Put 30 days and carry out anaerobic fermentation, obtain the clostridium butyricum fermentation product;

[0040] (2) Take Enterococcus faecalis and be mixed with sterile water to be 5% Enterococcus faecalis bacterium liquid, measure 5ml Enterococcus faecalis bacterium liquid and inoculate in 4 grams of fermentation additives, aerobic at 38 ℃ in fermenter Ferment for 15 days to obtain the Enterococcus faecalis fermentation product; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com