Device and method for preparation of lactobacillus acid water and application of lactobacillus acid water

A technology of lactic acid bacteria and lactic acid bacteria, which is applied in the field of equipment for preparing lactic acid bacteria acid water, can solve problems such as waste of resources, achieve the effects of small occupied equipment, high drinking frequency, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

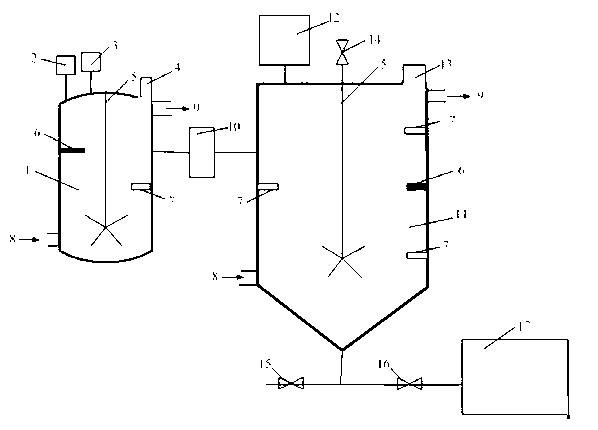

[0042] A method for preparing lactic acid bacteria acid water, comprising the steps of:

[0043] S1. Hydrolysis of cassava residue

[0044] In the hydrolysis tank 1, put 1.0t cassava residue into the inlet 4, and use dilute HNO 3 Hydrolyze by high-temperature treatment for 0.5 h; then cool down to 50 °C, add alkali solution to neutralize to a pH of about 7, and use a homogenizer 10 to make cassava dregs mash.

[0045] Among them, dilute HNO 30.5% HNO 3 Solution, filled in the acid tank 2; cassava residue and dilute HNO 3 The solid-to-liquid ratio is 1:4. The hydrolysis temperature is 98°C, indicated by thermometer 6. Alkaline solution selects 30% NaOH solution for use, and packs in the alkali-adding tank 3;

[0046] In addition, during the hydrolysis process, the stirring speed of the stirring paddle 5 in the hydrolysis tank 1 is controlled at 300 r / min, and the alkali neutralization process is displayed by the pH sensor 7 .

[0047] Activation of S2 lactic acid bacteri...

Embodiment 2

[0061] A method for preparing lactic acid bacteria acid water, comprising the steps of:

[0062] S1. Hydrolysis of cassava residue

[0063] In the hydrolysis tank 1, put 0.5 t of cassava residue into the inlet 4, and use dilute HNO 3 Hydrolysis by high-temperature treatment, the hydrolysis time is 1 hour; then after cooling down to 30°C, add alkali solution to neutralize to a pH of about 6, and use a homogenizer 10 to make cassava dregs mash.

[0064] Among them, dilute HNO 3 Contains 0.1% HNO 3 Aqueous solution, filled in the acid tank 2; cassava residue and dilute HNO 3 The solid-to-liquid ratio is 1:4. The hydrolysis temperature is about 80°C, which is displayed by thermometer 6.

[0065] Among them, the alkaline solution is 12% Na 2 CO 3 The solution is put into the alkali adding tank 3; in addition, during the hydrolysis process, the stirring speed of the stirring paddle 5 in the hydrolysis tank 1 is controlled at 120 r / min, and the alkali neutralization process is...

Embodiment 3

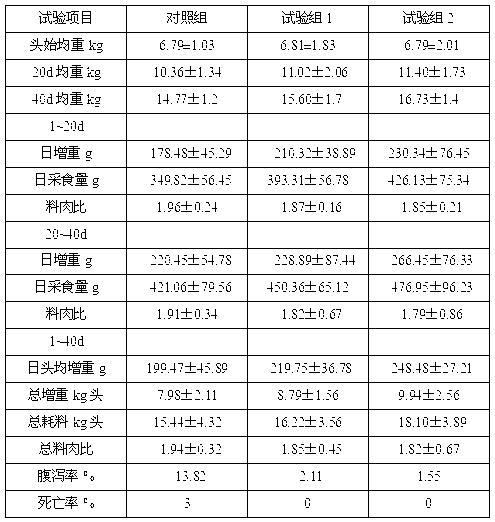

[0079] The test selected 90 dual nursery piglets aged 28±2 days, with basically the same body weight, with the same male-to-female ratio and no significant difference in average body weight (P>0.05), and divided them into 3 groups (control group, test group 1 and test group 2 ), each group has 30 heads, each group is divided into 2 circles, and each circle has 15 heads. The nursery piglets were provided by Guangdong No. 1 Food Co., Ltd., and the experiment site was carried out at the second line of Wusheling, Guanhu Base, Suixi, Zhanjiang, Guangdong.

[0080] The nursery piglets in the three groups were fed with the farm’s self-made rations, and they were given small meals and frequent meals, and they drank water freely, but the composition of the drinking water was different: the nursery piglets in the control group drank ordinary commercially available acid water and daily drinking water Mixed solution; what test group 1 drank was the lactic acid bacteria acid water prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com