Rhizoma corydalis pain killer and preparation method thereof

A technology of Yuanhu Zhitong Tablets and Hu Zhitong Tablets, which is applied in the direction of non-central analgesics, pharmaceutical formulas, medical preparations with non-active ingredients, etc. It can solve the problems of affecting drug absorption, destroying active ingredients, affecting the quality and efficacy of preparations, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

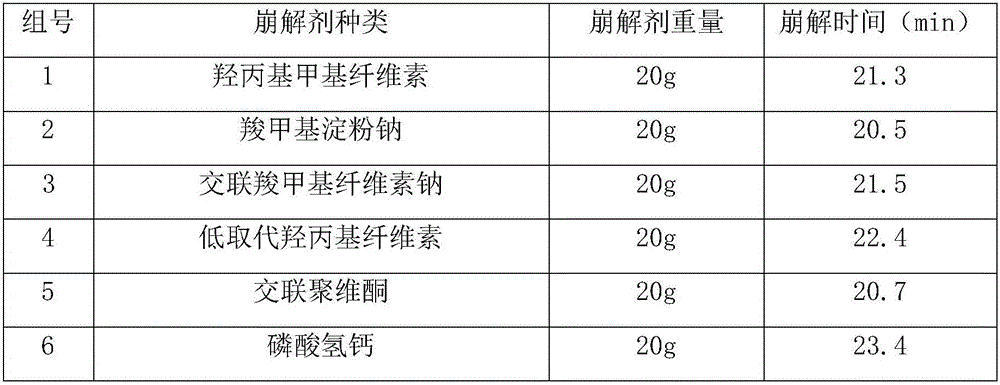

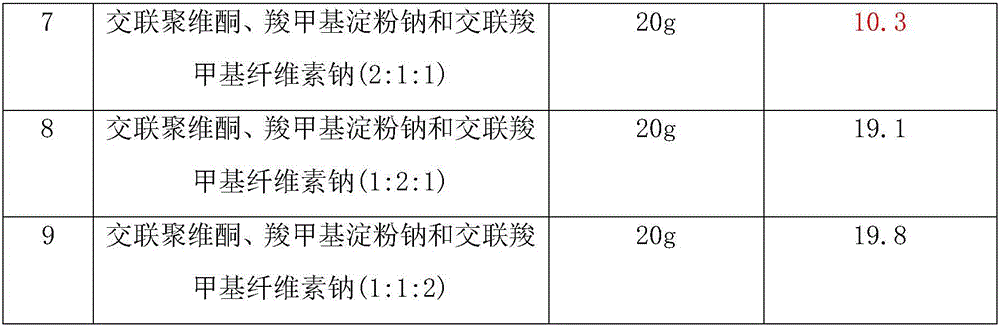

Embodiment 1

[0105] Vinegar Corydalis 445g Angelica dahurica 223g

[0106] Crospovidone 10g Sodium Carboxymethyl Starch 5g

[0107] Croscarmellose Sodium 5g.

[0108] The preparation method is:

[0109] 1 / 2 amount of vinegar corydalis is superfinely pulverized to obtain superfine powder; during the superfine pulverization process, 100g of dry ice is sprayed as a coolant; after superfine pulverization, 90-95% of the micropowder particle size is 3-6 microns; The remaining 1 / 2 amount of vinegar corydalis is ultrafinely pulverized to 5 microns, and the ultrafine powder is placed in CO 2 Soak in the extraction kettle for 3 hours, control the pressure in the extraction kettle to 25MPa; separate the soaked ultrafine powder in the separation kettle, control the separation pressure value in the separation kettle to 6MPa, heat to 40°C, keep for 5 hours, CO 2 The flow rate is maintained at 30Kg / h; the separated extract is dried to obtain extract A; the Angelica dahurica is soaked in 8 times the am...

Embodiment 2

[0111] Vinegar Corydalis 250g Angelica dahurica 300g

[0112] Crospovidone 6g Sodium Carboxymethyl Starch 7g

[0113] Croscarmellose sodium 3g;

[0114] 1 / 2 amount of vinegar corydalis is superfinely pulverized to obtain superfine powder; during the superfine pulverization process, 100g of dry ice is sprayed as a coolant; after superfine pulverization, 90-95% of the micropowder particle size is 3-6 microns; The remaining 1 / 2 amount of vinegar corydalis is ultrafinely pulverized to 5 microns, and the ultrafine powder is placed in CO 2 Soak in the extraction kettle for 3 hours, control the pressure in the extraction kettle to 25MPa; separate the soaked ultrafine powder in the separation kettle, control the separation pressure value in the separation kettle to 6MPa, heat to 40°C, keep for 5 hours, CO 2 The flow rate is maintained at 30Kg / h; the separated extract is dried to obtain extract A; the Angelica dahurica is soaked in 8 times the amount of water for 30 minutes, and 40g ...

Embodiment 3

[0116] Vinegar Corydalis 640g Angelica dahurica 130g

[0117] Crospovidone 14g Sodium Carboxymethyl Starch 3g

[0118] Croscarmellose sodium 7g;

[0119] 1 / 2 amount of vinegar corydalis is superfinely pulverized to obtain superfine powder; during the superfine pulverization process, 100g of dry ice is sprayed as a coolant; after superfine pulverization, 90-95% of the micropowder particle size is 3-6 microns; The remaining 1 / 2 amount of vinegar corydalis is ultrafinely pulverized to 5 microns, and the ultrafine powder is placed in CO 2 Soak in the extraction kettle for 3 hours, control the pressure in the extraction kettle to 25MPa; separate the soaked ultrafine powder in the separation kettle, control the separation pressure value in the separation kettle to 6MPa, heat to 40°C, keep for 5 hours, CO 2 The flow rate is maintained at 30Kg / h; the separated extract is dried to obtain extract A; the Angelica dahurica is soaked in 8 times the amount of water for 30 minutes, and 40g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com