Abalone culture water purification method

A technology for purifying aquaculture water and water body, which is applied in the field of water body purification, and can solve the problems of not being able to purify water body and not suitable for abalone aquaculture water body purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

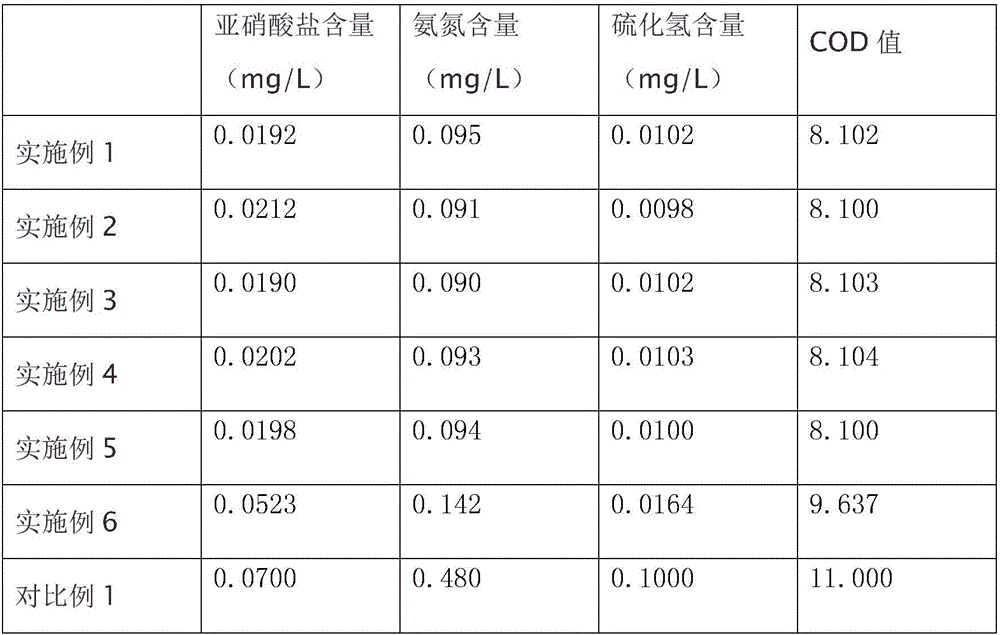

Examples

Embodiment 1

[0045] The complex is made up of the following materials in parts by weight:

[0046] 15 parts of macroporous adsorption resin,

[0047] 15 parts of columnar activated carbon,

[0048] 1 part of fluorinated epoxy resin,

[0049] 40 parts of adsorbent,

[0050] 10 servings of beneficial bacteria;

[0051] The adsorbent is composed of the following materials in parts by weight, 15 parts of aluminum oxide, 20 parts of polyacrylamide, and 15 parts of silica gel;

Embodiment 2

[0053] The complex is made up of the following materials in parts by weight:

[0054] 30 parts of macroporous adsorption resin,

[0055] 10 parts of columnar activated carbon,

[0056] 5 parts of fluorinated epoxy resin,

[0057] 20 parts of adsorbent,

[0058] 15 servings of beneficial bacteria;

[0059] The adsorbent is composed of the following materials in parts by weight, 10 parts of aluminum oxide, 25 parts of polyacrylamide, and 8 parts of silica gel;

Embodiment 3

[0061] The complex is made up of the following materials in parts by weight:

[0062] 20 parts of macroporous adsorption resin,

[0063] 12 parts of columnar activated carbon,

[0064] 3 parts of fluorinated epoxy resin,

[0065] 26 parts of adsorbent,

[0066] 12 servings of beneficial bacteria;

[0067] The adsorbent is composed of the following materials in parts by weight, 12 parts of aluminum oxide, 23 parts of polyacrylamide, and 10 parts of silica gel;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com