Economical thermal power plant ammonia-containing wastewater treatment system and economical thermal power plant ammonia-containing wastewater treatment method

A wastewater treatment system and thermal power plant technology, applied in water/sewage treatment, water treatment parameter control, degassed water/sewage treatment, etc., can solve the problems of undeveloped use of struvite, high operation requirements, and high cost of chemicals. Achieve the effects of improving the removal rate and efficiency of ammonia nitrogen, avoiding high vapor-liquid ratio, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

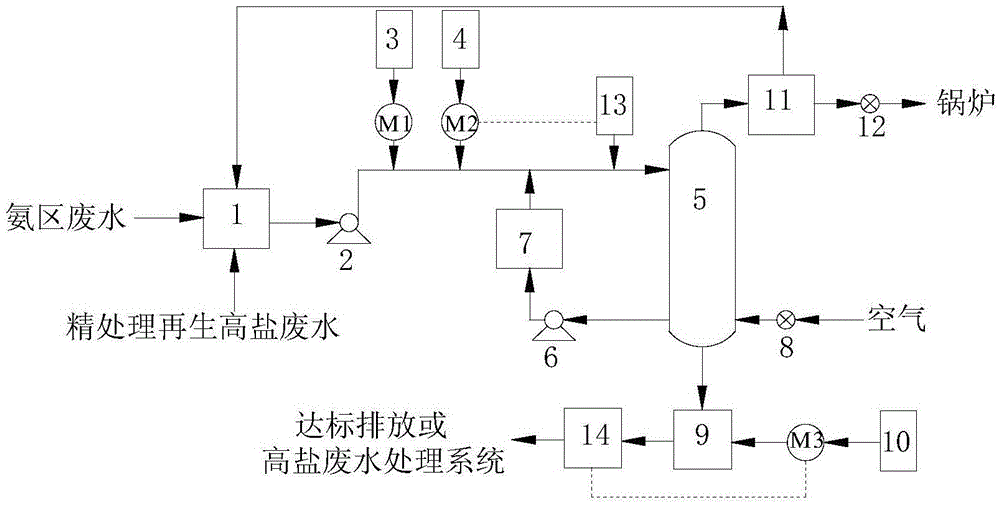

[0030] Ammonia zone wastewater (ρ(NH 3 -N): 150mg / L~250mg / L) and refined treatment of regenerated high-salt wastewater (ρ(NH 3-N): 1200mg / L~5000mg / L) are transported by the wastewater transport pump respectively, and mixed in the regulating tank 1 to form ammonia-containing wastewater, and the ammonia-containing wastewater is transported to the deamination tower 5 by the wastewater lifting pump 2, and deamination The deammonization agent in the agent storage tank 3 and the liquid caustic soda in the liquid caustic soda storage tank 4 enter the deammonization tower 5 after being mixed with the ammoniacal waste water through the deammonization agent metering pump M1 and the liquid caustic soda metering pump M2 respectively, and the deammonization tower 5. A second online pH meter 13 is provided at the entrance of the top, and the second online pH meter 13 is interlocked with the liquid caustic metering pump M2 for chain control, so that the pH of the mixed liquid entering the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com