A kind of preparation method of dense small-grain yig ceramics

A small-grain, ceramic technology, applied in the field of preparation of small-grain YIG ceramics, can solve the problems of reducing the performance of YIG ceramics, increasing the grain size, and low saturation magnetization, so as to keep the grain boundary diffusion active and inhibit the crystallization. Boundary migration, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

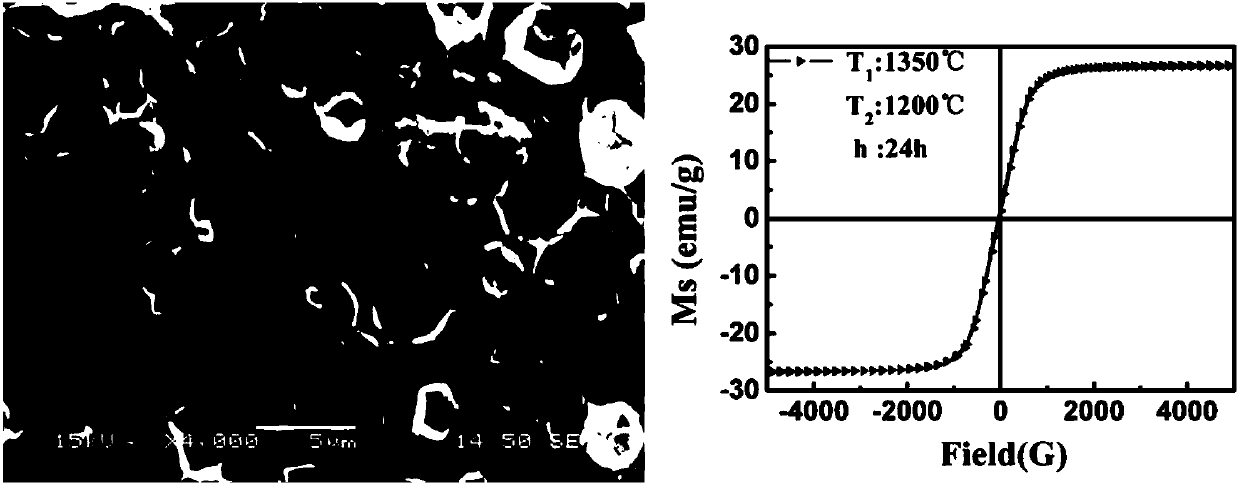

Embodiment 1

[0031] A kind of preparation method of compact small-grain YIG ceramics comprises the following steps:

[0032] (1) Ingredients: mix yttrium oxide and iron oxide according to chemical formula 3Y 2 o 3 +5Fe 2 o 3 =2Y 3 Fe 5 o 12 Proportioning is carried out to obtain raw materials;

[0033] (2) The first ball milling: put raw materials, balls, and alcohol in a ball mill according to the mass ratio of 20%, 45%, and 35% for wet ball milling. The ball milling time is 12 hours, so that the raw materials are mixed evenly to obtain a slurry ;

[0034] (3) drying: the slurry is placed in a constant temperature box to bake, remove alcohol, and grind in a mortar to obtain powder;

[0035] (4) Pre-burning: put the powder in a muffle furnace for pre-burning, the pre-burning temperature is 1100°C, and the holding time is 6 hours. After pre-burning, the raw materials undergo a chemical reaction (3Y 2 o 3 +5Fe 2 o 3 =2Y 3 Fe 5 o 12 ) to obtain the primary powder of YIG;

[00...

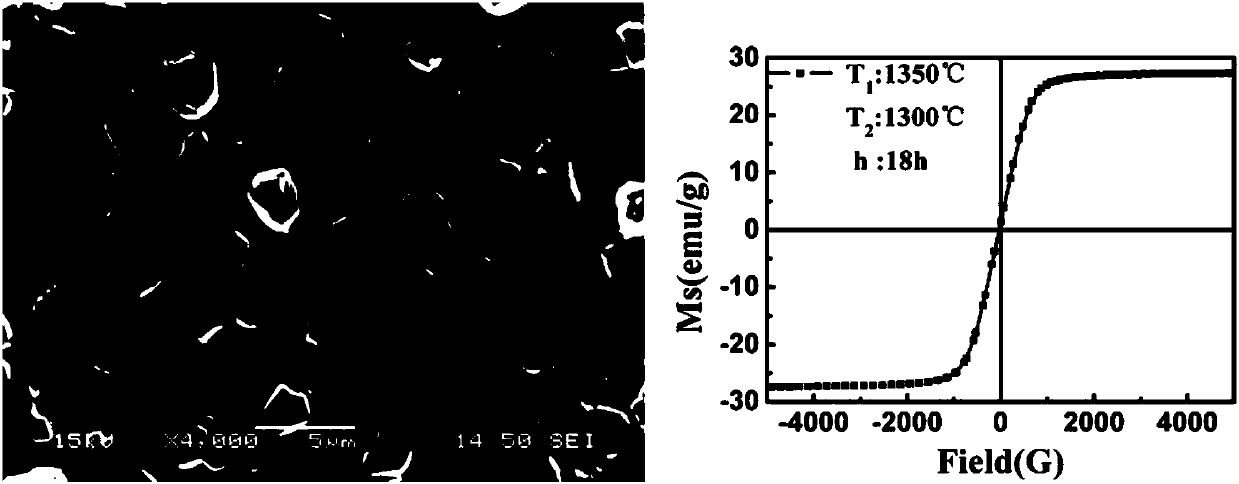

Embodiment 2

[0047] A kind of preparation method of compact small-grain YIG ceramics comprises the following steps:

[0048] (1) Ingredients: mix yttrium oxide and iron oxide according to chemical formula 3Y 2 o 3 +5Fe 2 o 3 =2Y 3 Fe 5 o 12 Proportioning is carried out to obtain raw materials;

[0049] (2) The first ball mill: put raw materials, balls and alcohol in a ball mill according to the mass ratio of 25%, 40%, and 35% for wet ball milling. The ball milling time is 24 hours, so that the raw materials are mixed evenly to obtain a slurry ;

[0050] (3) drying: the slurry is placed in a constant temperature box to bake, remove alcohol, and grind in a mortar to obtain powder;

[0051] (4) Pre-burning: put the powder in a muffle furnace for pre-burning, the pre-burning temperature is 1200°C, and the holding time is 6 hours. After pre-burning, the raw materials undergo a chemical reaction (3Y 2 o 3 +5Fe 2 o 3 =2Y 3 Fe 5 o 12 ), obtain YIG powder;

[0052] (5) The second ba...

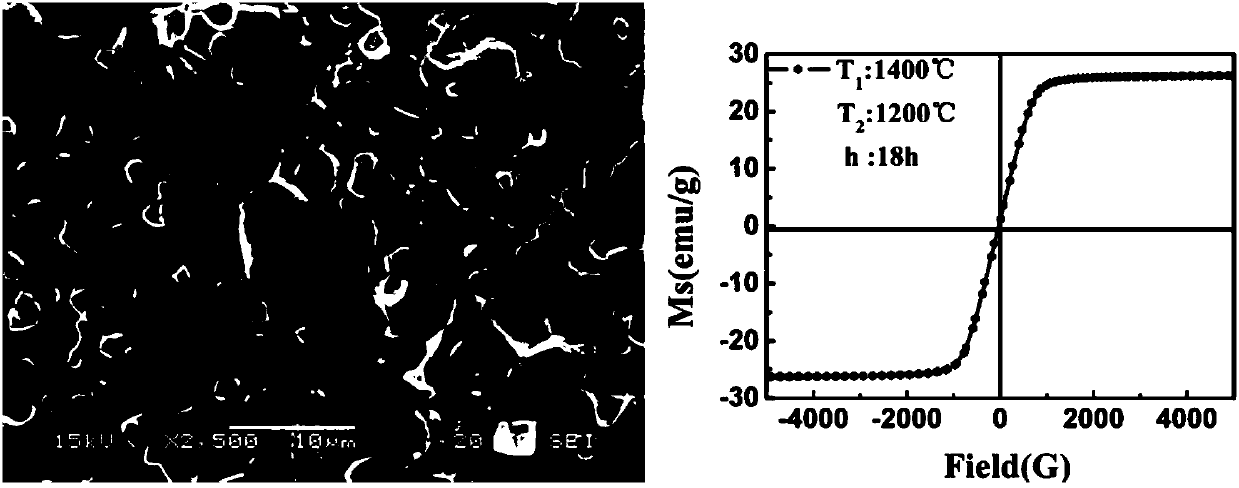

Embodiment 3

[0059] A kind of preparation method of compact small-grain YIG ceramics comprises the following steps:

[0060] (1) Ingredients: mix yttrium oxide and iron oxide according to chemical formula 3Y 2 o 3 +5Fe 2 o 3 =2Y 3 Fe 5 o 12 Proportioning is carried out to obtain raw materials;

[0061] (2) The first ball mill: put raw materials, balls and alcohol in a ball mill according to the mass ratio of 25%, 45%, and 30% for wet ball milling. The ball milling time is 12 hours, so that the raw materials are mixed evenly to obtain a slurry ;

[0062] (3) drying: the slurry is placed in a constant temperature box to bake, remove alcohol, and grind in a mortar to obtain powder;

[0063] (4) Pre-burning: put the powder in a muffle furnace for pre-burning, the pre-burning temperature is 1100°C, and the holding time is 6 hours. After pre-burning, the raw materials undergo a chemical reaction (3Y 2 o 3 +5Fe 2 o 3 =2Y 3 Fe 5 o 12 ) to obtain YIG powder;

[0064] (5) The second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com