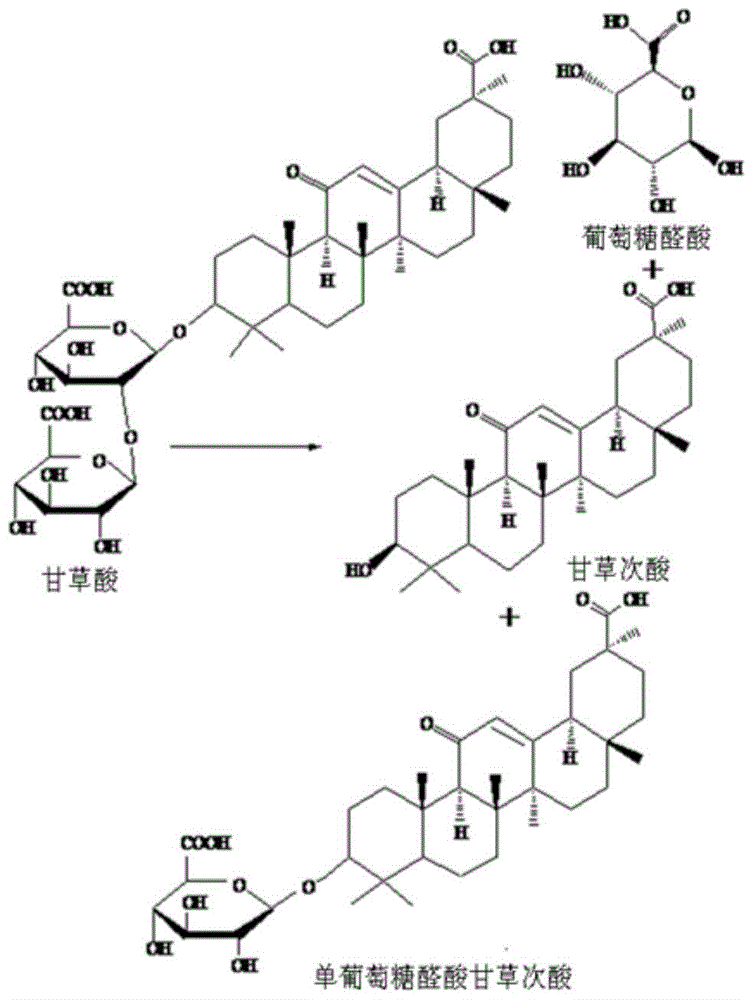

Preparation method of glycyrrhetinic acid monoglucuronide

A technology of glycyrrhetinic acid aldehyde and licorice aldehyde, applied in the field of preparation of glycyrrhetinic acid monoglucuronate, can solve the problems of complex operation, difficult process control, high cost, etc., and achieve scientific and reasonable process, simple and easy operation, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

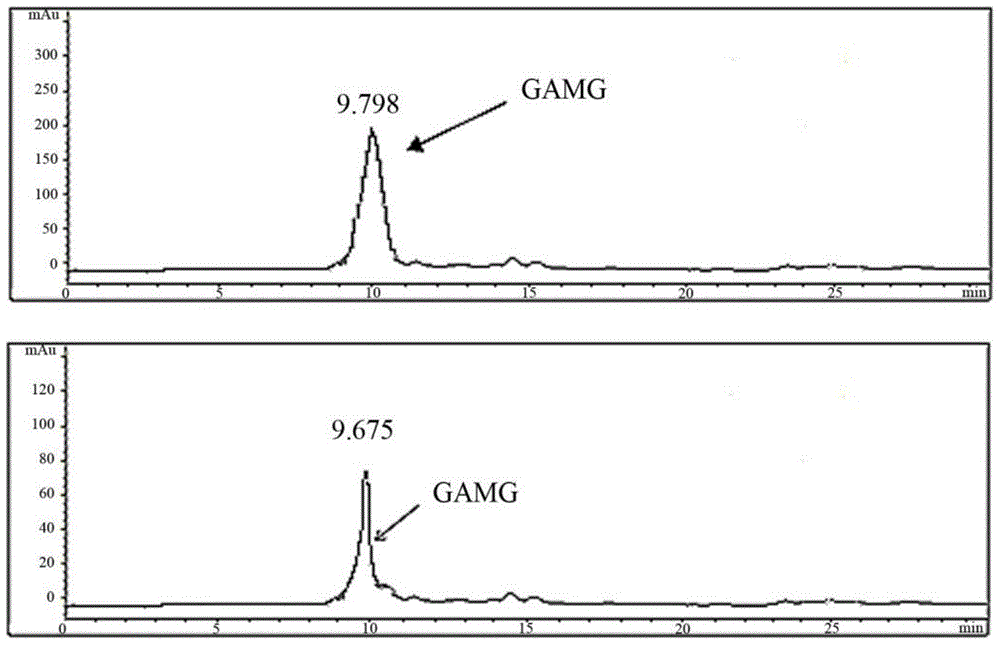

Embodiment 1

[0036] 1. Preparation of glycyrrhetinic acid monoglucuronic acid extract: first soak licorice with 5% acetic acid solution, the liquid-solid ratio is 3:1, the soaking temperature is 60°C, and the soaking time is 4h; the soaked licorice is drained Dry water, carry out steam explosion treatment, the pressure is 10MPa, and the explosion time is 10min; after the steam explosion pretreatment, the licorice is subjected to microwave-assisted extraction, the extraction liquid-solid ratio is 30:1, the extraction time is 30min, the temperature is 60°C, microwave The power is 300W, the stirring speed is 150rpm, and the monoglucuronic acid glycyrrhetinic acid extract is obtained after the extraction is completed.

[0037] 2. Clarification treatment: Centrifuge the obtained extract of glycyrrhetinic acid monoglucuronide at a speed of 4200 rpm / min for 15 minutes to obtain a clarified solution of glycyrrhetinic acid monoglucuronide, and discard the precipitate.

[0038] 3. Separation and pur...

Embodiment 2

[0041] 1. Preparation of glycyrrhetinic acid monoglucuronic acid extract: first soak licorice with 5% sulfuric acid solution, the liquid-solid ratio is 3:1, the soaking temperature is 60°C, and the soaking time is 4h; the soaked licorice is drained Dry water, carry out steam explosion treatment, the pressure is 10MPa, and the explosion time is 10min; after the steam explosion pretreatment, the licorice is subjected to microwave-assisted extraction, the extraction liquid-solid ratio is 30:1, the extraction time is 30min, the temperature is 60°C, microwave The power is 300W, the stirring speed is 150rpm, and the monoglucuronic acid glycyrrhetinic acid extract is obtained after the extraction is completed.

[0042] 2. Clarification treatment: Centrifuge the obtained extract of glycyrrhetinic acid monoglucuronide at a speed of 4200 rpm / min for 15 minutes to obtain a clarified solution of glycyrrhetinic acid monoglucuronide, and discard the precipitate.

[0043] 3. Separation and pur...

Embodiment 3

[0046] 1. Preparation of glycyrrhetinic acid monoglucuronic acid extract: first soak licorice with 5% sulfuric acid, the liquid-solid ratio is 2:1, the soaking temperature is 70°C, and the soaking time is 3h; drain the soaked licorice Moisture, steam explosion treatment, the pressure is 10MPa, and the explosion time is 15min; after the steam explosion pretreatment, the licorice is subjected to microwave-assisted extraction, the extraction liquid-solid ratio is 50:1, the extraction time is 60min, the temperature is 70°C, and the microwave power The stirring speed is 600W, the stirring speed is 250rpm, and the extract of monoglucuronic acid glycyrrhetinic acid is obtained after the extraction is completed.

[0047] 2. Clarification treatment: Centrifuge the obtained extract of glycyrrhetinic acid monoglucuronide at a speed of 3600 rpm / min for 15 minutes to obtain a clarified solution of glycyrrhetinic acid monoglucuronide, and discard the precipitate.

[0048] 3. Separation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com