A temperature-sensitive copolymer gel profile control and water blocking agent and its preparation method and application

A technology of profile control water shutoff agent and copolymer, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as unrecognizable, influence of plugging effect, failure to form gel, etc., to achieve time controllable, Simple process, easy to inject effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

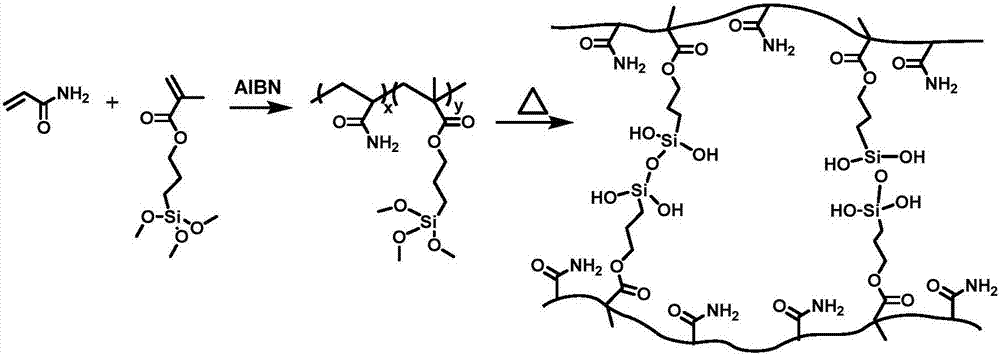

[0045] This embodiment provides a preparation method of a temperature-sensitive copolymer gel profile control and water shutoff agent, which includes the following steps:

[0046] Add 1.18g of acrylamide (AM), 100mL of tetrahydrofuran (THF) and 790μL of γ-methacryloxypropyltrimethoxysilane (MPS) to a 250mL three-neck flask with a magnet, and stir to form a uniform and transparent solution. The molar ratio of AM and MPS is 5:1, and the total content of AM and MPS is 2w / v% of the solution;

[0047] N was introduced into the above solution 2 Remove the oxygen in the solution, and ventilate for 15 minutes, dissolve 20 mg of initiator azobisisobutyronitrile (AIBN) in 1 mL of THF, pour it into the above-mentioned three-necked bottle, and heat the three-necked bottle in an oil bath at 60°C , and then under the protection of nitrogen, magnetically stirred for 24h, then took out the three-necked bottle, terminated the reaction, and obtained a random copolymer solution; the reaction pr...

Embodiment 2

[0057] This embodiment provides a preparation method of a temperature-sensitive copolymer gel profile control and water shutoff agent, which includes the following steps:

[0058] Add 3.7g of acrylamide (AM), 100mL of tetrahydrofuran (THF) and 1.24mL of γ-methacryloxypropyl trimethoxysilane (MPS) into a 250mL three-necked flask with a magnet, and stir to form a uniform and transparent solution. , the molar ratio of AM and MPS is 10:1, and the total content of AM and MPS is 5w / v% of the solution;

[0059] N was introduced into the above solution 2 Remove the oxygen in the solution, and ventilate for 15 minutes, dissolve 50 mg of the initiator azobisisobutyronitrile (AIBN) in 1 mL of THF, pour it into the above-mentioned three-necked bottle, and heat the three-necked bottle in an oil bath at 60°C , and then under the protection of nitrogen, magnetically stirred for 24h, then took out the three-necked flask, terminated the reaction, and obtained a random copolymer solution;

[...

Embodiment 3

[0064] This embodiment provides a preparation method of a temperature-sensitive copolymer gel profile control and water shutoff agent, which includes the following steps:

[0065] Add 1.85g of acrylamide (AM), 50mL of N,N-dimethylformamide (DMF) and 0.62mL of γ-methacryloxypropyltrimethoxysilane (MPS) into a 100mL three-necked flask with a magnet. ), stirred into a uniform and transparent solution, the molar ratio of AM and MPS is 10:1, and the total content of AM and MPS is 5w / v% of the solution;

[0066] N was introduced into the above solution 2 Remove the oxygen in the solution, and ventilate for 15 minutes, dissolve 12.5 mg of initiator azobisisobutyronitrile (AIBN) in 1 mL of DMF, pour it into the above-mentioned three-necked bottle, and place the three-necked bottle in an oil bath at 60°C Heating, then under the protection of nitrogen, magnetically stirred for 24h, then took out the three-necked flask, terminated the reaction, and obtained a random copolymer solution; ...

PUM

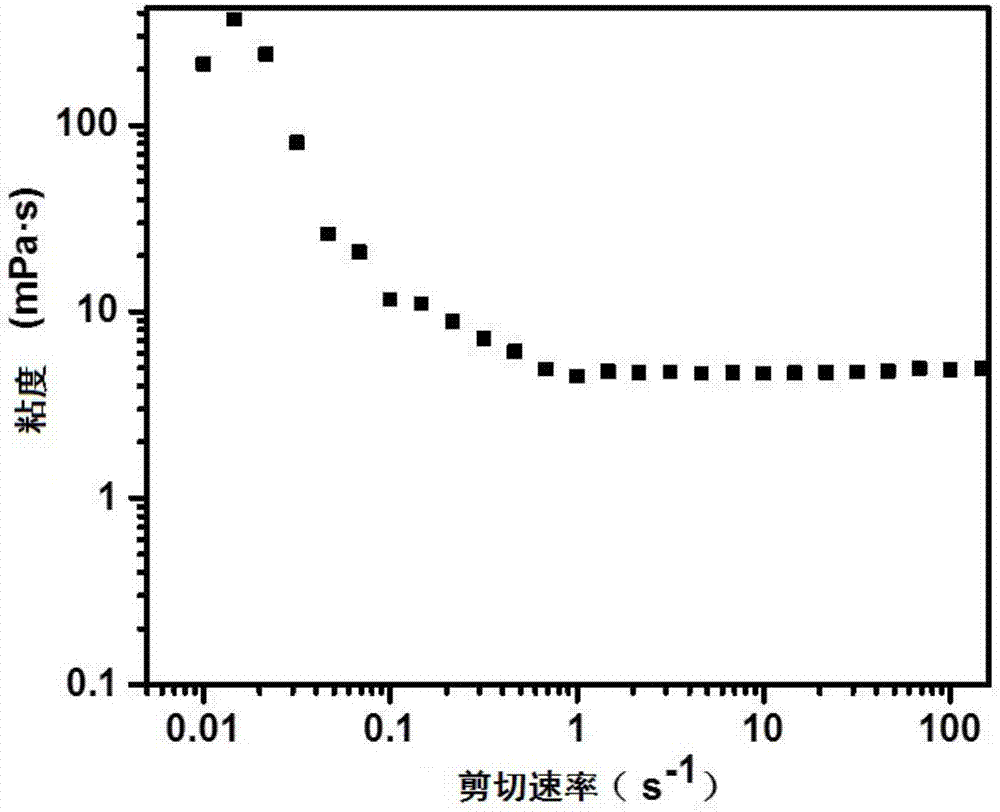

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com