A kind of thermoplastic rubber foam material FRB and preparation method thereof

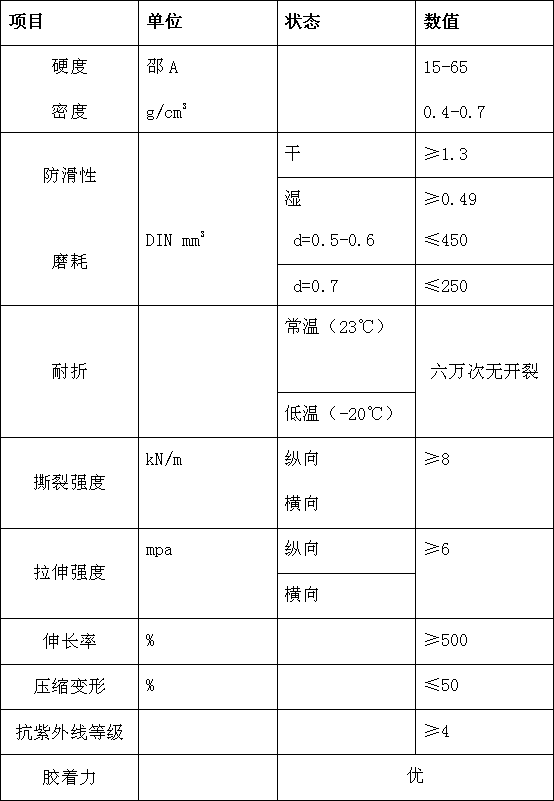

A technology of thermoplastic rubber and foaming materials, applied in the field of new materials, can solve problems such as poor tortuosity, poor tear strength, and uneven cells, and achieve high low-temperature bending strength, high tensile strength, and good rubber texture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

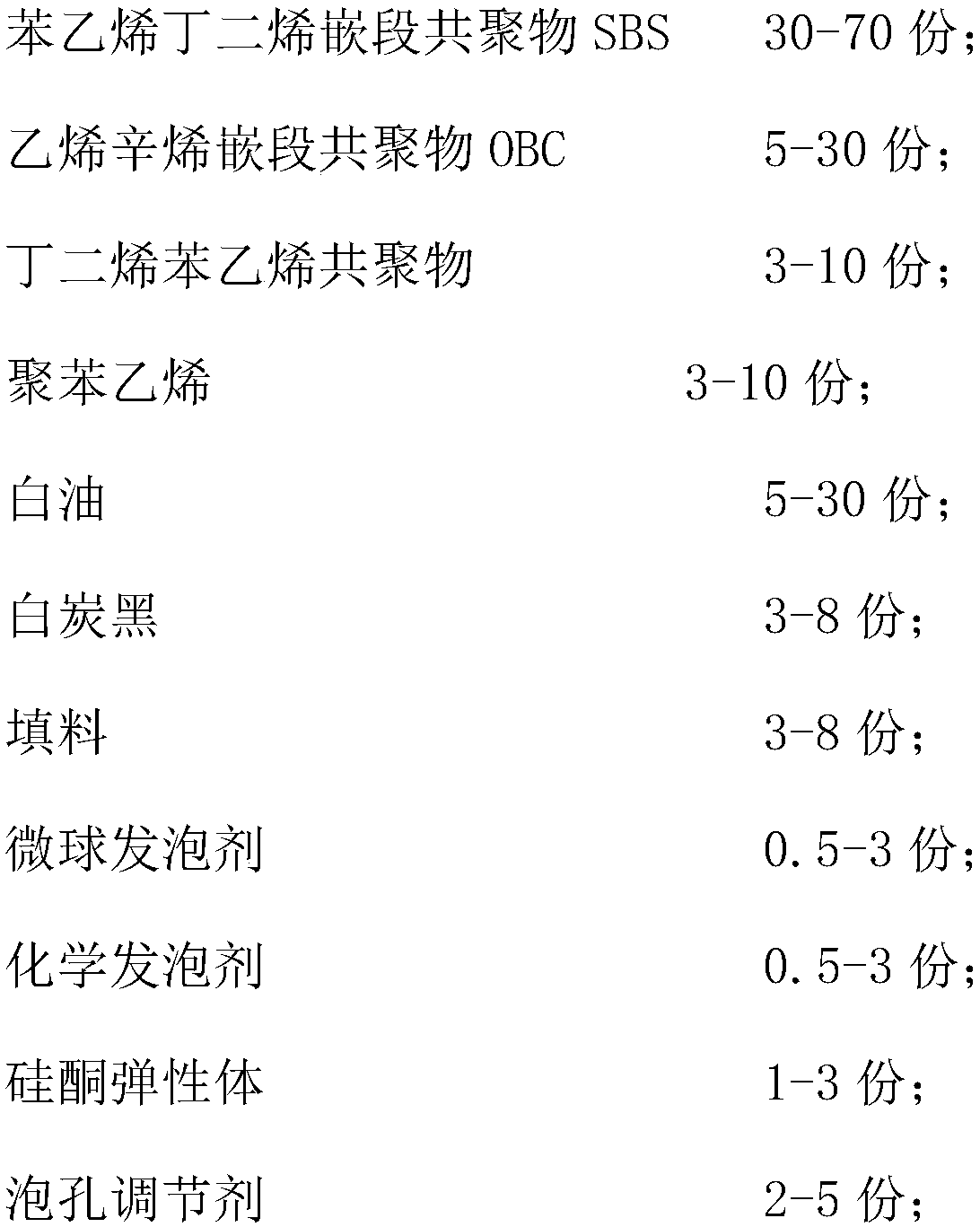

[0083] A thermoplastic rubber foaming material FRB, prepared from the following raw materials according to the following weight ratio:

[0084] Styrene butadiene block copolymer SBS 50 parts

[0085] Ethylene octene block copolymer OBC 18 parts

[0086] Butadiene styrene copolymer 7 parts

[0087] Polystyrene PS 7 parts

[0088] 18 parts of white oil

[0089] White carbon black 6 parts

[0090] Filling 6 parts

[0091] Microsphere foaming agent 2 parts

[0092] Chemical foaming agent 2 parts

[0093] 2 parts silicone elastomer

[0094] Cell regulator 3 parts.

[0095] A method for preparing thermoplastic rubber foam material FRB, the process is as follows:

[0096] According to the above ratio, first fully stir SBS, OBC and white oil for 90 minutes, then add butadiene styrene copolymer and polystyrene, and stir for 45 minutes at the same time, mix well, and then put in the desiccant Stir the ball blowing agent and other raw materials other than the chemical blowing a...

Embodiment 2

[0098] A thermoplastic rubber foaming material FRB, prepared from the following raw materials according to the following weight ratio:

[0099] Styrene butadiene block copolymer SBS 30 parts

[0100] Ethylene Octene Block Copolymer OBC 5 parts

[0101] 3 parts butadiene styrene copolymer

[0102] Polystyrene PS 3 parts

[0103] White oil 5 parts

[0104] White carbon black 3 parts

[0105] Filling 3 parts

[0106] Microsphere foaming agent 0.5 part

[0107] 0.5 parts of chemical foaming agent

[0108] 1 part silicone elastomer

[0109] Cell regulator 2 parts.

[0110] A method for preparing thermoplastic rubber foam material FRB, the process is as follows:

[0111] According to the above ratio, firstly mix SBS, OBC and white oil fully for 60 minutes, then add butadiene styrene copolymer and polystyrene, stir for 30 minutes at the same time, mix well, and then add Stir the ball blowing agent and other raw materials other than the chemical blowing agent, let the butadi...

Embodiment 3

[0113] A thermoplastic rubber foaming material FRB, prepared from the following raw materials according to the following weight ratio:

[0114] Styrene butadiene block copolymer SBS 70 parts

[0115] Ethylene Octene Block Copolymer OBC 30 parts

[0116] Butadiene styrene copolymer 10 parts

[0117] Polystyrene PS 10 parts

[0118] 30 parts white oil

[0119] White carbon black 8 parts

[0120] Filling 8 servings

[0121] Microsphere foaming agent 3 parts

[0122] 3 parts chemical blowing agent

[0123] 3 parts silicone elastomer

[0124] Cell regulator 5 parts.

[0125] A method for preparing thermoplastic rubber foam material FRB, the process is as follows:

[0126] According to the above ratio, firstly mix SBS, OBC and white oil fully for 120 minutes, then add butadiene styrene copolymer and polystyrene, and stir for 60 minutes at the same time, mix well, and then put in desiccant Stir the ball blowing agent and other raw materials other than the chemical blowing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com