Sterilizing polyester resin

A technology of polyester resin and compound antibacterial agent, which is applied in the field of bactericidal polyester resin, can solve the problems of poor bactericidal effect, achieve the effect of increasing comprehensiveness, good compatibility, and improving bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

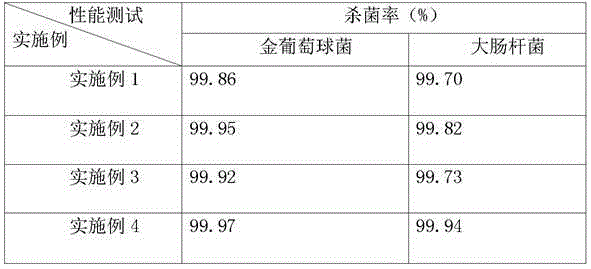

Examples

Embodiment 1

[0021] A bactericidal polyester resin, comprising the following components by weight: 95 parts of PBT, 5 parts of PET, 0.2 parts of a composite antibacterial agent; the composite antibacterial agent is composed of the following components: the composite antibacterial agent consists of the following components It is composed by parts by weight: 21 parts of zeolite powder, 10 parts of nano-titanium dioxide, 15 parts of nano-silver oxide, and 15 parts of polyhexamethylene guanidine phosphate.

[0022] A kind of preparation method of above-mentioned bactericidal polyester resin, comprises the following steps:

[0023] a. Mix and stir the zeolite powder and nano-titanium dioxide, stir and mix for 4 minutes at 90 rpm at room temperature, and dry.

[0024] b. Mix and stir PBT and PET, and stir and mix for 10 minutes at 70 rpm at 150°C;

[0025] c. Add the zeolite powder and nano-titanium dioxide mixture through step a and the PBT and PET mixture through step b into the mixer, and ad...

Embodiment 2

[0028] A bactericidal polyester resin, comprising the following components by weight: 95 parts of PBT, 5 parts of PET, 0.4 parts of a composite antibacterial agent; the composite antibacterial agent is composed of the following components: the composite antibacterial agent consists of the following components It is composed by parts by weight: 21 parts of zeolite powder, 10 parts of nano-titanium dioxide, 15 parts of nano-silver oxide, and 15 parts of polyhexamethylene guanidine phosphate.

[0029] A kind of preparation method of above-mentioned bactericidal polyester resin, comprises the following steps:

[0030] a. Mix and stir the zeolite powder and nano-titanium dioxide, stir and mix for 5 minutes at 140 rpm at room temperature, and dry.

[0031] b. Mix and stir PBT and PET, and stir and mix for 10 minutes at 80 rpm at 150°C;

[0032] c. Add the zeolite powder and nano-titanium dioxide mixture through step a and the PBT and PET mixture through step b into the mixer, and a...

Embodiment 3

[0035] A bactericidal polyester resin, comprising the following components by weight: 95 parts of PBT, 5 parts of PET, 0.2 parts of composite antibacterial agent, 0.3 part of dispersant ethylene bis stearamide, 3 parts of compatibilizer polypropylene grafted maleic anhydride part; the composite antibacterial agent is made up of the following components: the composite antibacterial agent is made up of the following components in parts by weight: 21 parts of zeolite powder, 10 parts of nano-titanium dioxide, 15 parts of nano-silver oxide, polyhexamethylene 15 parts of guanidine phosphate.

[0036] A kind of preparation method of above-mentioned bactericidal polyester resin, comprises the following steps:

[0037] a. Mix and stir the zeolite powder and nano-titanium dioxide, stir and mix for 4 minutes at 90 rpm at room temperature, and dry.

[0038] b. Mix and stir PBT and PET, and stir and mix for 10 minutes at 70 rpm at 150°C;

[0039] c. Add the zeolite powder, nano-titanium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com