Magnetic molecular sieve loaded TiO2 composite photocatalyst and preparation method thereof

A technology of magnetic molecules and compound light, which is applied in the field of adsorption porous materials and photocatalysis, can solve the problems of difficult separation and low catalytic efficiency, and achieve the effects of high-efficiency recovery, improved photocatalytic activity, and narrowed bandgap width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

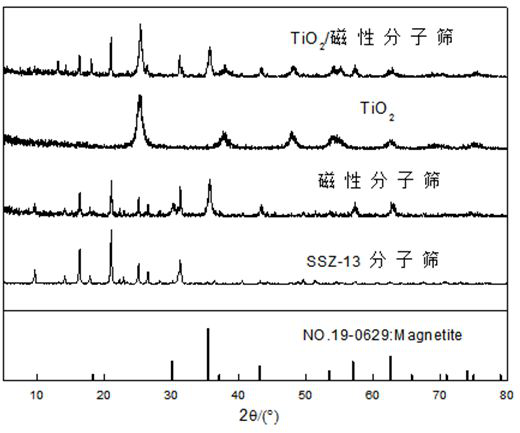

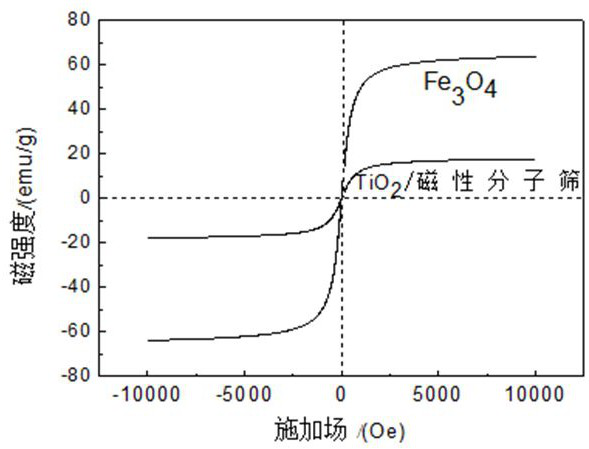

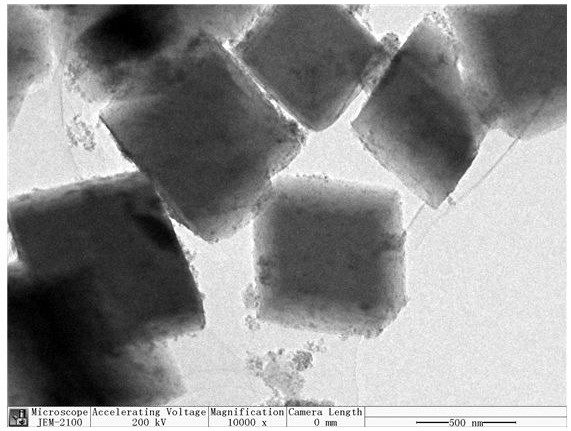

[0025] Add 6.96 g of silica, 12.82 g of deionized water, 2.72 g of aluminum sulfate, 0.2 g of sodium hydroxide, and 2.0 g of trimethyladamantyl ammonium hydroxide into a 100 mL beaker, then add 0.5 g of molecular sieve seed crystals and stir 3 h to prepare the initial molecular sieve gel, add 10 g of nano-iron ferric oxide dispersion with a solid mass fraction of 25% to the initial gel, ultrasonically disperse for 1 h, put it into a stainless steel reactor and put it in an oven at 165 ℃ for 24 h, the obtained product was washed with deionized water three times, dried and ground at 100 ℃ to obtain a magnetic molecular sieve sample.

[0026]Measure 10 mL of tetrabutyl titanate and 18 mL of absolute ethanol and mix it as liquid A, then measure 3 mL of deionized water and 10 mL of absolute ethanol and mix it as liquid B, stir vigorously for 20 minutes at the same time, add dropwise to liquid A Add 2 mL of glacial acetic acid, and add 4.2 g of prepared magnetic molecular sieves, sl...

Embodiment 2

[0032] Add 6.96 g of white carbon black, 12.82 g of deionized water, 2.72 g of aluminum sulfate, 0.1 g of sodium hydroxide, and 1.0 g of trimethyladamantyl ammonium hydroxide into a 100 mL beaker, then add 0.2 g of molecular sieve seed crystals and stir 3 h to prepare the initial molecular sieve gel, add 10 g of nano-iron ferric oxide dispersion with a solid mass fraction of 25% to the initial gel, ultrasonically disperse for 1 h, put it into a stainless steel reactor and put it in an oven at 165 ℃ for 24 h, the obtained product was washed with deionized water three times, dried and ground at 100 ℃ to obtain a magnetic molecular sieve sample.

[0033] Measure 10 mL of tetrabutyl titanate and 18 mL of absolute ethanol and mix it as liquid A, then measure 3 mL of deionized water and 10 mL of absolute ethanol and mix it as liquid B, stir vigorously for 20 minutes at the same time, add dropwise to liquid A Add 2 mL of glacial acetic acid, and add 4.2 g of prepared magnetic molecul...

Embodiment 3

[0035] Add 6.96 g of silica, 12.82 g of deionized water, 2.72 g of aluminum sulfate, 0.2 g of sodium hydroxide, and 2.0 g of trimethyladamantyl ammonium hydroxide into a 100 mL beaker, then add 0.5 g of molecular sieve seed crystals and stir 3 h to prepare the initial molecular sieve gel, add 10 g of nano-iron ferric oxide dispersion with a solid mass fraction of 25% to the initial gel, ultrasonically disperse for 1 h, put it into a stainless steel reactor and put it in an oven at 170 ℃ for 12 h, the obtained product was washed three times with deionized water, dried and ground at 100 ℃ to obtain a magnetic molecular sieve sample.

[0036] Measure 10 mL of tetrabutyl titanate and 18 mL of absolute ethanol and mix it as liquid A, then measure 3 mL of deionized water and 10 mL of absolute ethanol and mix it as liquid B, stir vigorously for 20 minutes at the same time, add dropwise to liquid A Add 2 mL of glacial acetic acid, and add 4.2 g of prepared magnetic molecular sieves, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com