Preparation method of cadmium sulfide self-doped titanium dioxide composite catalyst

A composite catalyst, titanium dioxide technology, used in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve the problems of poor photocatalytic decomposition of H2S activity, insufficient light absorption utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

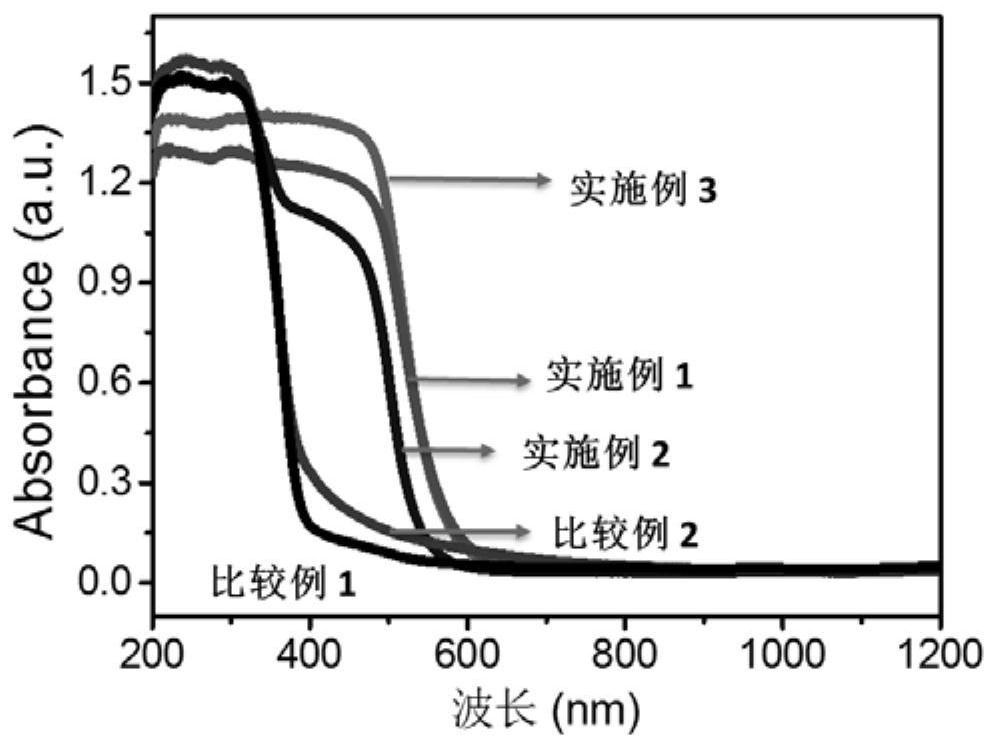

Embodiment 1

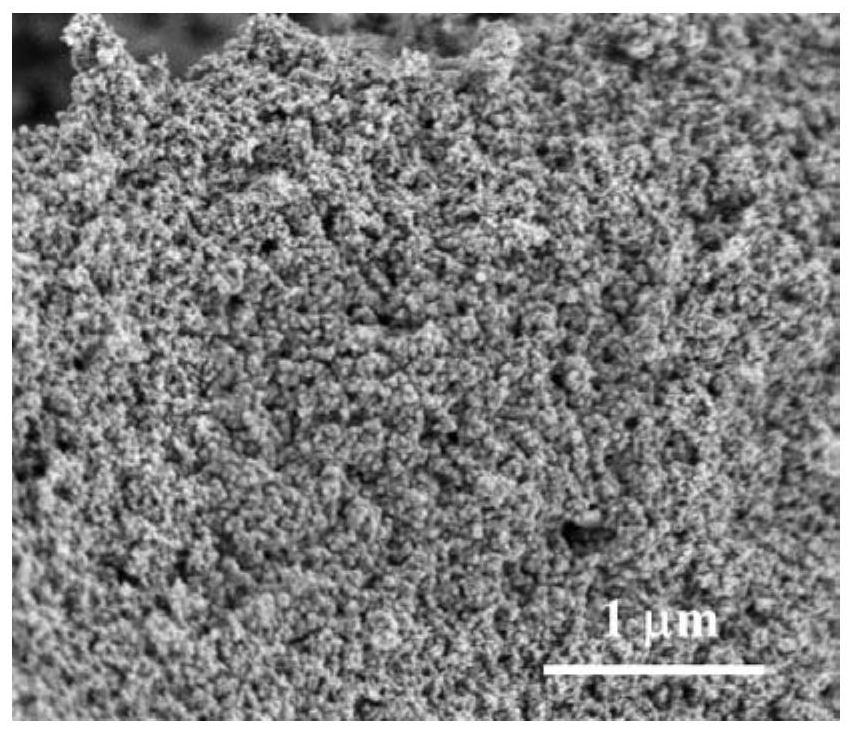

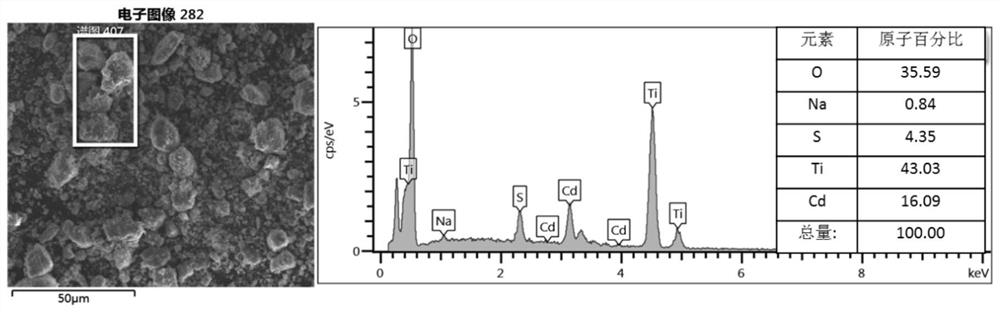

[0077] 1. Preparation of cadmium sulfide self-doped titanium dioxide composite photocatalyst

[0078] (1) Add 5ml of tetrabutyl titanate to 15ml of absolute ethanol, stir and mix evenly (weight ratio is 2.5) to obtain solution A;

[0079] (2) Cadmium acetate, water, nitric acid and ethanol are mixed uniformly to obtain solution B, wherein the Ti element is counted as titanium dioxide, and the Cd element is counted as CdS, and the weight ratio of the two is 20%; the weight ratio of tetrabutyl titanate to ethanol is 2.5, and the mol ratios of water to tetrabutyl titanate and tetrabutyl titanate to nitric acid are 2.8 and 3.7 respectively;

[0080] (3) Drop solution B into solution A and stir for 30 minutes to obtain mixed solution C;

[0081] (4) Add thiourea to mixed solution C, stir for 30 minutes to obtain mixed solution D, wherein the molar ratio of thiourea to cadmium acetate is 1.5;

[0082] (5) Add the sodium borohydride powder to the mixed liquid D under stirring, and ...

Embodiment 2

[0089] 1. Preparation of cadmium sulfide self-doped titanium dioxide composite photocatalyst

[0090] (1) Add 5ml of tetrabutyl titanate to 15ml of absolute ethanol, stir and mix evenly (weight ratio is 2.5) to obtain solution A;

[0091] (2) Cadmium acetate, water, nitric acid and ethanol are mixed uniformly to obtain solution B, wherein the Ti element is counted as titanium dioxide, and the Cd element is counted as CdS, and the weight ratio of the two is 10%; the weight ratio of tetrabutyl titanate to ethanol is 2.5, and the mol ratios of water to tetrabutyl titanate and tetrabutyl titanate to nitric acid are 2.8 and 3.7 respectively;

[0092] (3) Drop solution B into solution A and stir for 30 minutes to obtain mixed solution C;

[0093] (4) Add thiourea to mixed solution C, stir for 30 minutes to obtain mixed solution D, wherein the molar ratio of thiourea to cadmium acetate is 1.5;

[0094] (5) Add sodium borohydride powder to mixed solution D under stirring, and mix un...

Embodiment 3

[0099] 1. Preparation of cadmium sulfide self-doped titanium dioxide composite photocatalyst

[0100] (1) Add 5ml of tetrabutyl titanate to 15ml of absolute ethanol, stir and mix evenly (weight ratio is 2.5) to obtain solution A;

[0101] (2) Cadmium acetate, water, nitric acid and ethanol are mixed uniformly to obtain solution B, wherein the Ti element is counted as titanium dioxide, and the Cd element is counted as CdS, and the weight ratio of the two is 30%; the weight ratio of tetrabutyl titanate to ethanol is 2.5, and the mol ratios of water to tetrabutyl titanate and tetrabutyl titanate to nitric acid are 2.8 and 3.7 respectively;

[0102] (3) Drop solution B into solution A and stir for 30 minutes to obtain mixed solution C;

[0103] (4) Add thiourea to mixed solution C, stir for 30 minutes to obtain mixed solution D, wherein the molar ratio of thiourea to cadmium acetate is 1.5;

[0104] (5) Add sodium borohydride powder to mixed solution D under stirring, and mix un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com