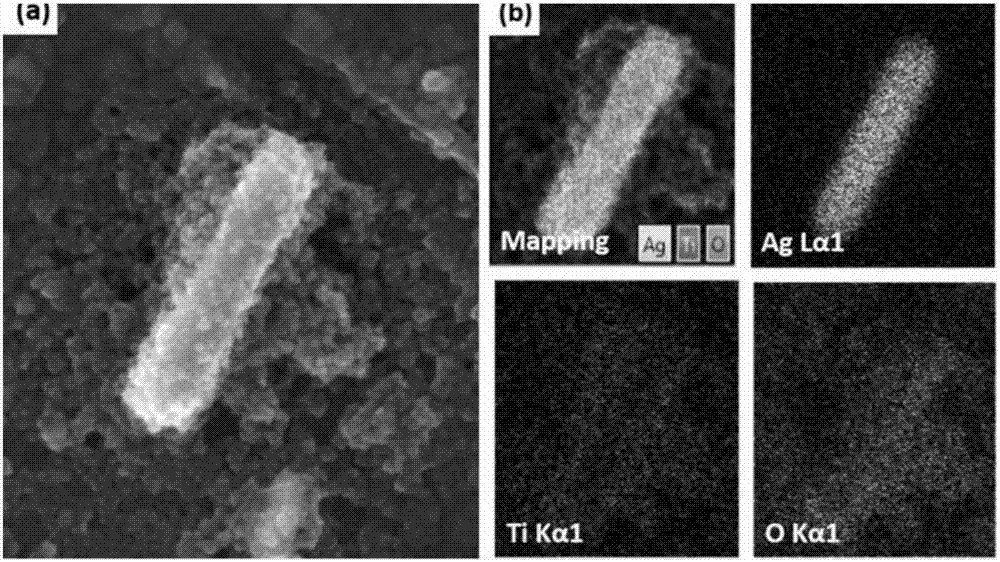

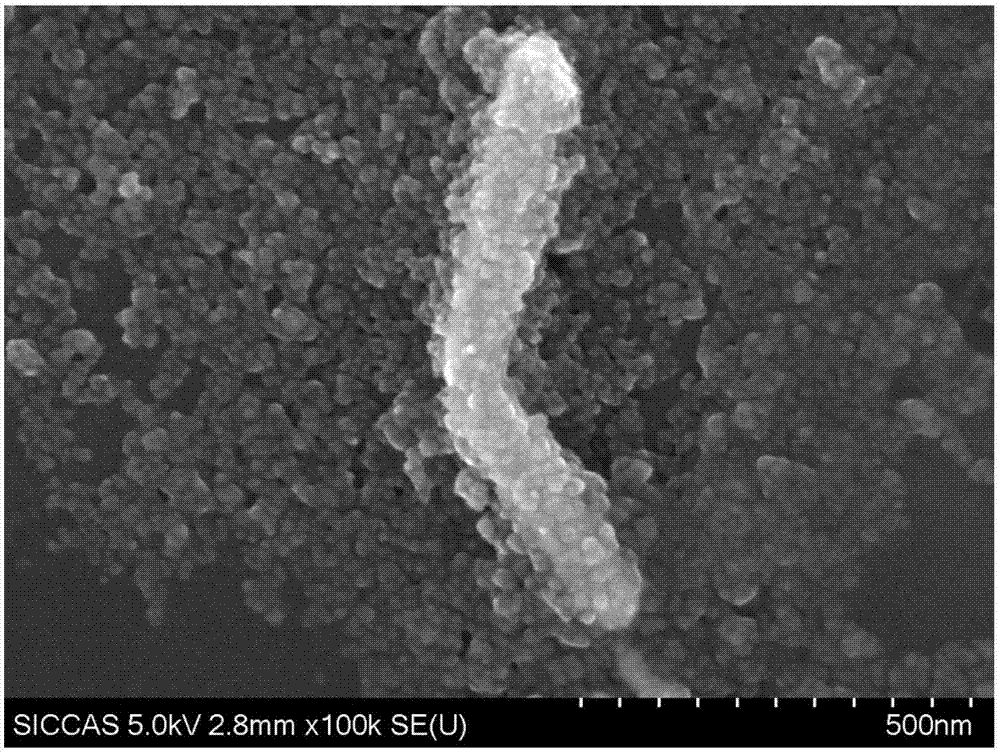

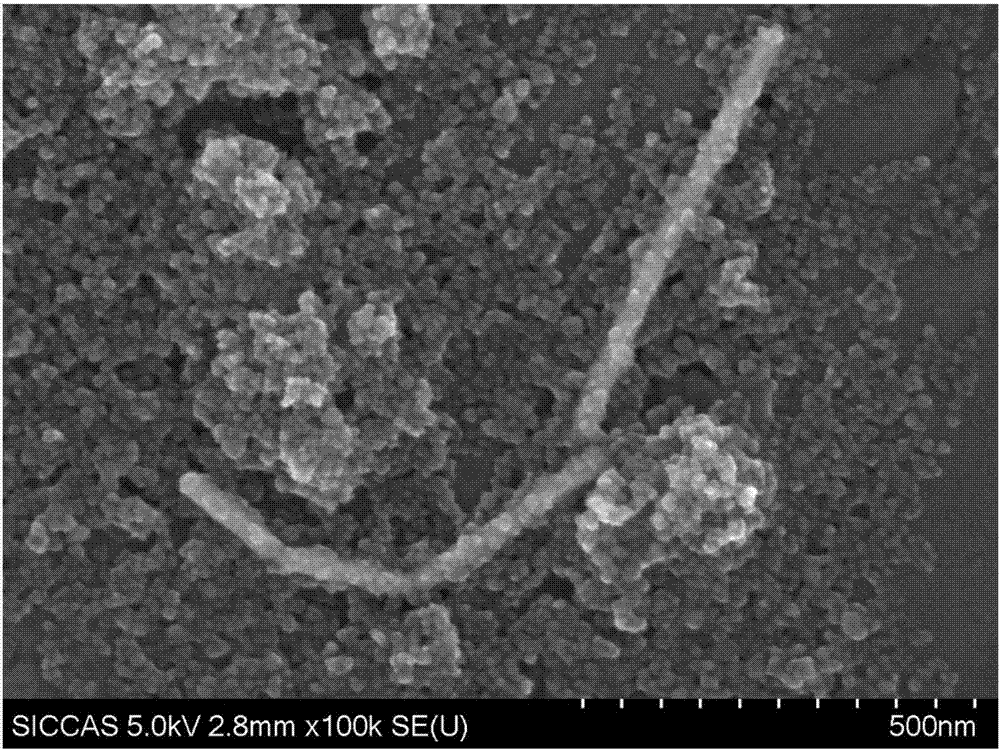

Silver nanorod and titanium dioxide composite material as well as preparation method and application thereof

A technology of silver nanorods and titanium dioxide, which is applied in the field of photocatalytic materials, can solve the problems of insufficient utilization, limited enhancement, and low concentration of pollutants, so as to increase the utilization of solar spectrum, improve photocatalytic activity, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]Disperse 0.875mg of silver nanorods in 30ml of ethanol and ultrasonically disperse for 30 minutes to obtain a uniform and stable dispersion of silver nanorods with good dispersion. Add 1.5ml of tetrabutyl titanate to the dispersion, continue stirring and then add dropwise 1ml of deionized water, continue to stir for 20min, after fully stirring, transfer to a 50ml reaction kettle, put in an oven at 160°C for 10h, then centrifuge, wash and dry to obtain silver nanorod-titanium dioxide composite powder, in which the silver nanorod The weight ratio is 0.25%.

[0037] Take 0.2g of silver nanorod-titanium dioxide powder, add 2g of absolute ethanol, and ball mill for 24 hours to obtain a silver nanorod-titanium dioxide ethanol dispersion, which is scraped on a 5cm*10cm glass plate and dried naturally to obtain a silver nanorod- Titanium dioxide coating, the quality control of the coating is 0.1g.

Embodiment 2

[0039] Disperse 1.75mg of silver nanorods in 30ml of ethanol, ultrasonically disperse for 30 minutes to obtain a uniform and stable dispersion of silver nanorods with good dispersion, add 1.5ml of tetrabutyl titanate to the dispersion, continue stirring and then add dropwise 1ml of deionized water, continue to stir for 20min, after fully stirring, transfer to a 50ml reaction kettle, put in an oven at 160°C for 10h, then centrifuge, wash and dry to obtain silver nanorod-titanium dioxide composite powder, in which silver nanorod The weight ratio is 0.5%.

[0040] Take 0.2g of silver nanorod-titanium dioxide powder, add 2g of absolute ethanol, and ball mill for 24 hours to obtain a silver nanorod-titanium dioxide ethanol dispersion, which is scraped on a 5cm*10cm glass plate and dried naturally to obtain a silver nanorod- Titanium dioxide coating, the quality control of the coating is 0.1g.

Embodiment 3

[0042] Disperse 2.625mg of silver nanorods in 30ml of ethanol and ultrasonically disperse for 30 minutes to obtain a uniform and stable dispersion of silver nanorods with good dispersion. Add 1.5ml of tetrabutyl titanate to the dispersion, and add 1ml of it dropwise after continuous stirring. deionized water, continue to stir for 20min, after fully stirring, transfer to a 50ml reaction kettle, put in an oven at 160°C for 10h, then centrifuge, wash and dry to obtain silver nanorod-titanium dioxide composite material powder, in which the silver nanorod The weight ratio is 0.75%.

[0043] Take 0.2g of silver nanorod-titanium dioxide powder, add 2g of absolute ethanol, and ball mill for 24 hours to obtain a silver nanorod-titanium dioxide ethanol dispersion, which is scraped on a 5cm*10cm glass plate and dried naturally to obtain a silver nanorod- Titanium dioxide coating, the quality control of the coating is 0.1g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com