Self-cleaning coating, self-cleaning fiber, self-cleaning carpet and uses thereof

A self-cleaning and coating technology, applied in the field of self-cleaning, can solve the problems of disappearance of hydrophilicity, pollution, affecting the service life of products, etc., to reduce the electrostatic adsorption force, improve the self-cleaning rate, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

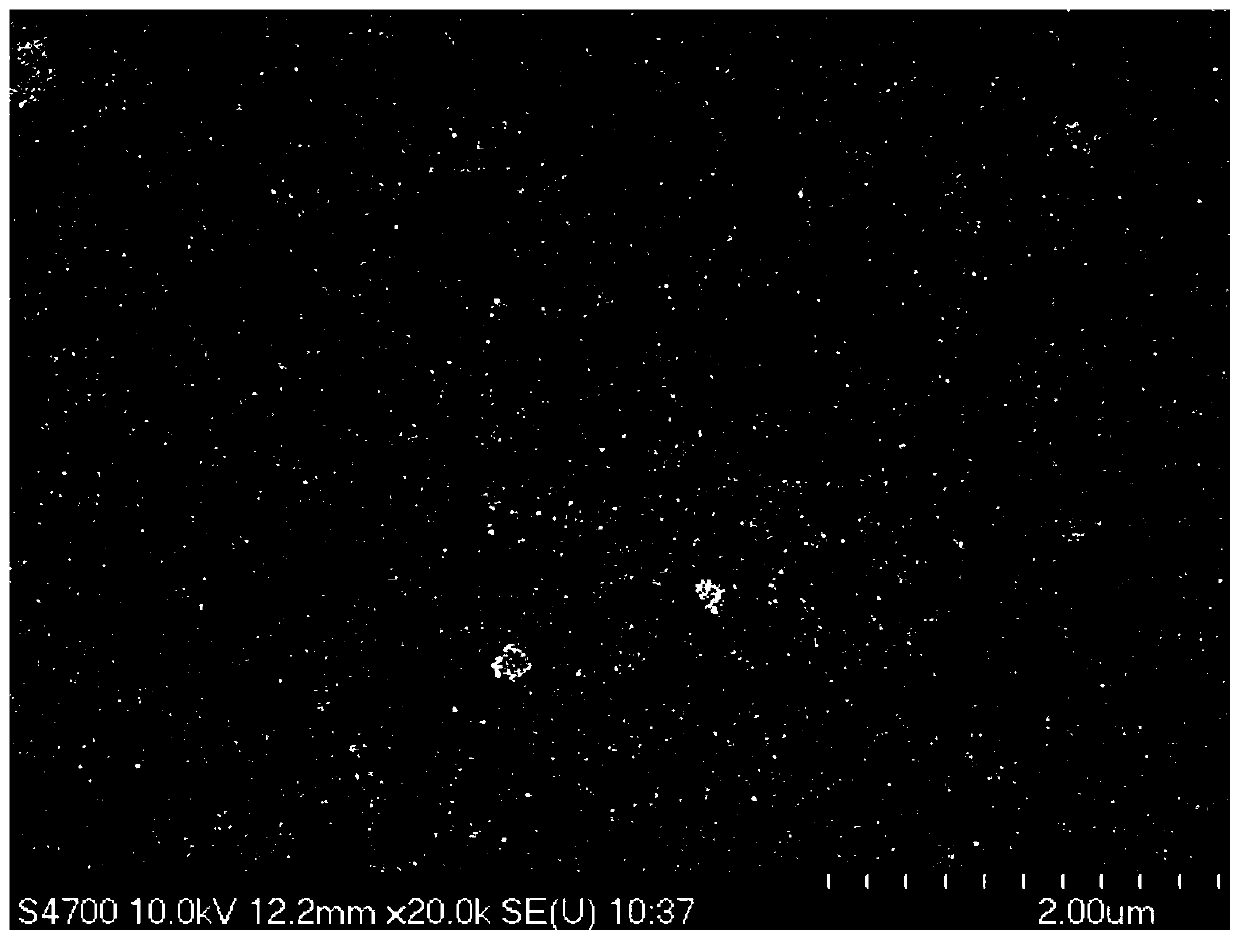

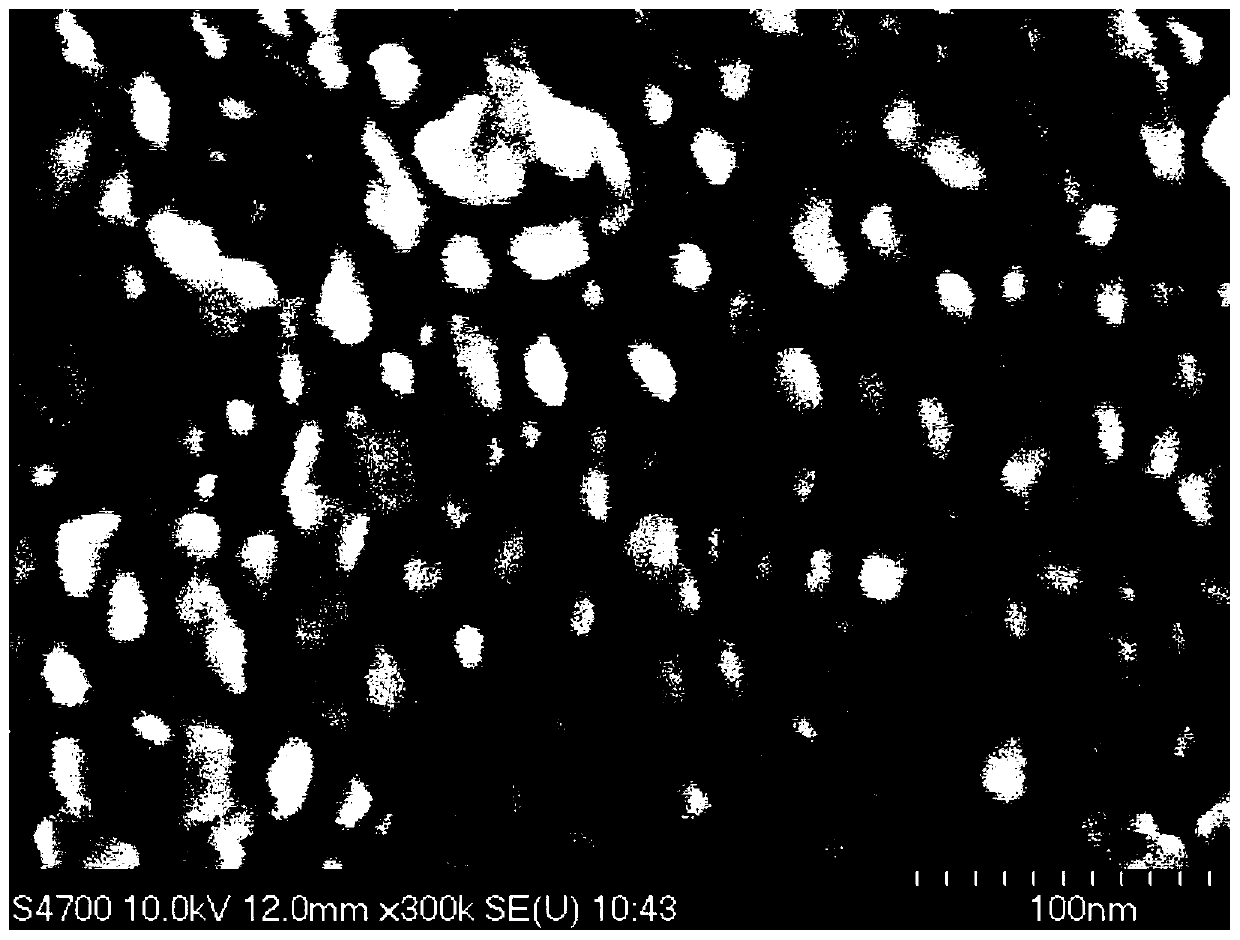

[0092] The preparation method of coating: get titanium chloride 19g and dissolve in 1000ml water, slowly add ammoniacal liquor (30%) 30g with the speed of 1g per minute, after stirring for 1 hour, after washing precipitation 3 times with deionized water, add hydrogen peroxide (30%) % solution) 100g degummed under the environment of 15 ℃ for 12 hours, put it into the hydrothermal reaction kettle and heat it under the condition of 120 ℃ for 8 hours to obtain a translucent nitrogen-doped titanium oxide sol, which is a spindle Shape, control the aspect ratio of the spindle shape between 2 and 4, and the crystallinity > 95%.

[0093] The above-mentioned paint is sprayed on the glass by physical deposition method, and prepared into Glass Product Example 1-1;

[0094]Apply the above paint evenly on the surface of the nylon fiber, then soak the fiber in 1% perfluorooctyl silane methanol solution for 24 hours, take it out and dry it to get self-cleaning carpet example 1-2.

Embodiment 2

[0096] The preparation method of coating: get titanium sulfate 24g to be dissolved in 1000ml water, slowly add ammoniacal liquor (30%) 30g with the speed of 1g per minute, after stirring for 1 hour, after washing precipitation 3 times with deionized water, add hydrogen peroxide (30%) Solution) 100g degummed at 20°C for 12 hours to obtain a stable sol, add 1g of triethanolamine, put it into a hydrothermal reaction kettle and heat it at 110°C for 12 hours to obtain a translucent nitrogen-doped A sol of titanium oxide. The sol is in a spindle shape, the aspect ratio of the spindle shape is controlled between 2 and 4, and the crystallinity is more than 95%.

[0097] The above-mentioned paint is sprayed on the glass by physical deposition method to prepare glass product Example 2-1;

[0098] Apply the above paint evenly on the surface of the nylon fiber, then soak the fiber in 1% perfluorooctyl silane methanol solution for 24 hours, take it out and dry it to obtain Self-cleaning C...

Embodiment 3

[0100] The preparation method of the paint: Take 8g of 8nm spherical hydroxyl surface-modified titanium oxide, disperse it in 1000ml of water, stir it at high speed for 30 minutes, and set it aside for use. Take 15g of 10nm spherical silica alkaline sol (30%wt), disperse in the above dispersion, and stir for 10 minutes normally. Take 10 g of 50 nm spherical silica alkaline sol (40% wt), disperse it in the above dispersion liquid, and stir it for 10 minutes normally.

[0101] The above-mentioned paint is sprayed on the glass by physical deposition method to prepare glass product Example 3-1;

[0102] Apply the above paint evenly on the surface of the nylon fiber, then soak the fiber in 1% perfluorooctyl silane methanol solution for 24 hours, take it out and dry it to obtain Self-cleaning Carpet Example 3-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com