Waterborne acrylic wood coating and preparation method thereof

A technology of water-based acrylic and wood coatings, which is applied in coatings and other directions, can solve problems such as lack of air purification and general adhesion, and achieve the effects of reducing production costs, good compatibility, and good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

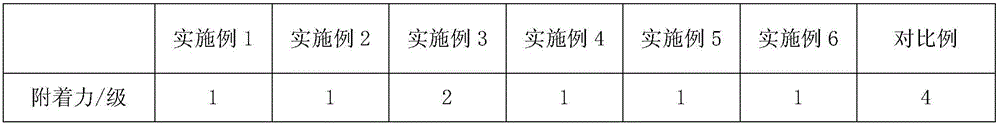

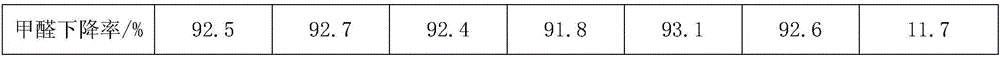

Examples

Embodiment 1

[0029] Water-based acrylic wood coatings, including the following components by weight: 41 parts of water-based pure acrylic emulsion, 24 parts of starch emulsion, 2 parts of dipropylene glycol methyl ether, 1 part of silicone leveling agent, 1.2 parts of associative polyurethane thickener 2.4 parts of calcium naphthenate, 15 parts of water, 4.2 parts of tributyl phosphate, 0.1 part of Cathone, 9 parts of filler diatomaceous earth, and 0.7 parts of sodium polyacrylate.

[0030] The preparation method of this wood coating is:

[0031] (1) sweet potato starch, potato starch, purple potato starch that mass ratio is 3:3:1 is added in the phosphoric acid solution that mass concentration is 3%, the total weight of sweet potato starch, potato starch, purple potato starch and the weight of phosphoric acid solution The ratio is 1:3, stir the starch solution evenly into a slurry, move it into a constant temperature water bath, heat it to 50°C, stir and react at a constant temperature fo...

Embodiment 2

[0036] Water-based acrylic wood coatings, including the following components by weight: 43 parts of water-based pure acrylic emulsion, 22 parts of starch emulsion, 4 parts of dipropylene glycol methyl ether, 0.5 part of silicone leveling agent, 1.4 parts of associative polyurethane thickener 2.7 parts of calcium naphthenate, 17 parts of water, 4.4 parts of tributyl phosphate, 0.2 parts of Cathone, 11 parts of filler colloidal calcium carbonate, and 0.9 parts of sodium polyacrylate.

[0037] Its preparation method is identical with embodiment 1.

Embodiment 3

[0039] Water-based acrylic wood coatings, including the following components by weight: 45 parts of water-based pure acrylic emulsion, 20 parts of starch emulsion, 2.5 parts of dipropylene glycol methyl ether, 0.7 parts of silicone leveling agent, 1.1 parts of associative polyurethane thickener 2.5 parts of calcium naphthenate, 19 parts of water, 4.8 parts of tributyl phosphate, 0.1 part of Cathone, 13 parts of filler colloidal calcium carbonate, and 1 part of sodium polyacrylate.

[0040] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com