Centrifugal blower vane designed based on load method

A centrifugal fan and load calculation technology, which is applied to the components, mechanical equipment, engine functions and other directions of the pumping device for elastic fluid, can solve the problems of difficulty in improving the fan, blindness of the blades, etc., and achieves the improvement of fan performance, Effects of stable static pressure growth and improved jet-wake structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0037] A centrifugal fan blade designed based on the load method, the load calculation formula used is:

[0038] δ=ρ·ω·Δω(1)

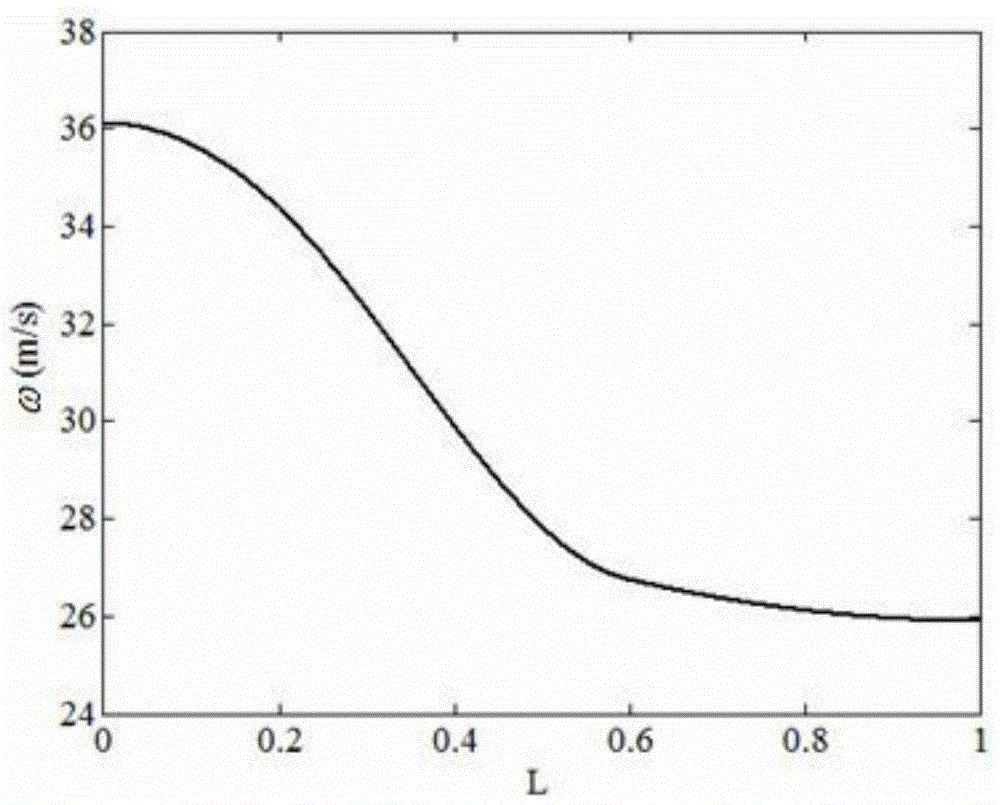

[0039] Among them, δ is the load; ρ is the fluid density in the flow direction, and since the research scope belongs to incompressible fluid, ρ is a constant value; ω is the average relative velocity of the fluid on the centerline of the blade passage, and Δω is the fluid density on the suction surface and the pressure surface Average relative velocity difference.

[0040] Since the average relative velocity of the blade path centerline is similar to the average relative velocity of the suction surface and the pressure surface, the formula (1) can be written as:

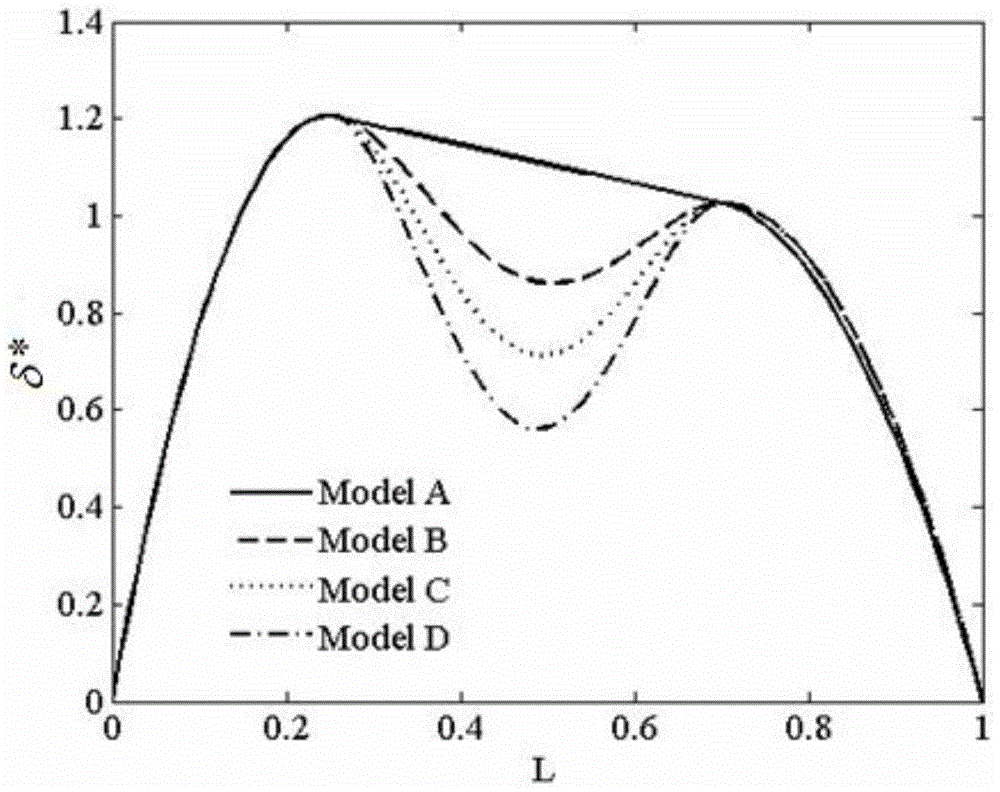

[0041] δ=ρ·S·ω 2 (2)

[0042] S = Δ ω ω = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com