Ultra-low frequency dielectric loss-based DC cable extrusion insulation aging state evaluation method

A DC cable and insulation aging technology, which is applied in the direction of testing dielectric strength, dielectric performance measurement, measuring electricity, etc., can solve problems such as irrelevant research, cable aging, and large influence, and achieve small sample size and reduction Effects of systematic errors, effects of reduced accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in more detail below in combination with specific embodiments.

[0022] The method for evaluating the aging state of DC cable extrusion insulation based on ultra-low frequency dielectric loss proposed by the present invention includes the following steps:

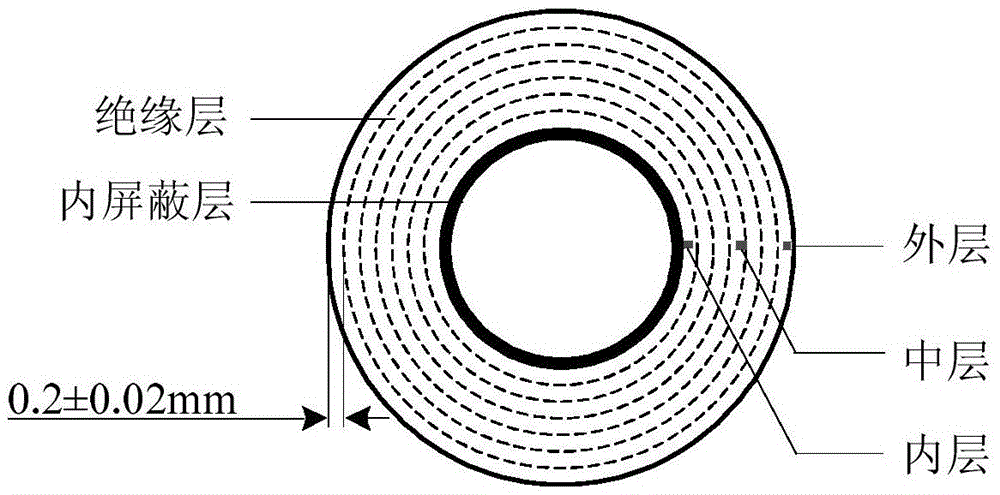

[0023] Step 1: Prepare sliced specimens,

[0024] Take the new and pre-qualified high-voltage DC extruded cables as objects, respectively take cable sections about 100mm long, remove the conductor core and strip off all parts other than the insulation shielding, and perform circumferential cutting along the circumferential direction of the cable (such as Peel the fruit peel), cut the insulation ring into a slice sample with a thickness of about 0.2±0.02mm, and divide the insulation into three parts in the radial direction, which are called the inner layer, the middle layer and the outer layer, such as figure 1 As shown, cut 3 pieces of samples at positions corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com