Production line spraying and drying process temperature control method based on active-disturbance-rejection control (ADRC) technology

A temperature control method and ADRC technology, applied in the field of control, can solve problems such as nonlinearity and large hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] A temperature control method for spraying and drying process of a production line based on ADRC technology, comprising the following steps:

[0093] The first step is to establish the mathematical model of the controlled object in the spraying and drying process of the production line;

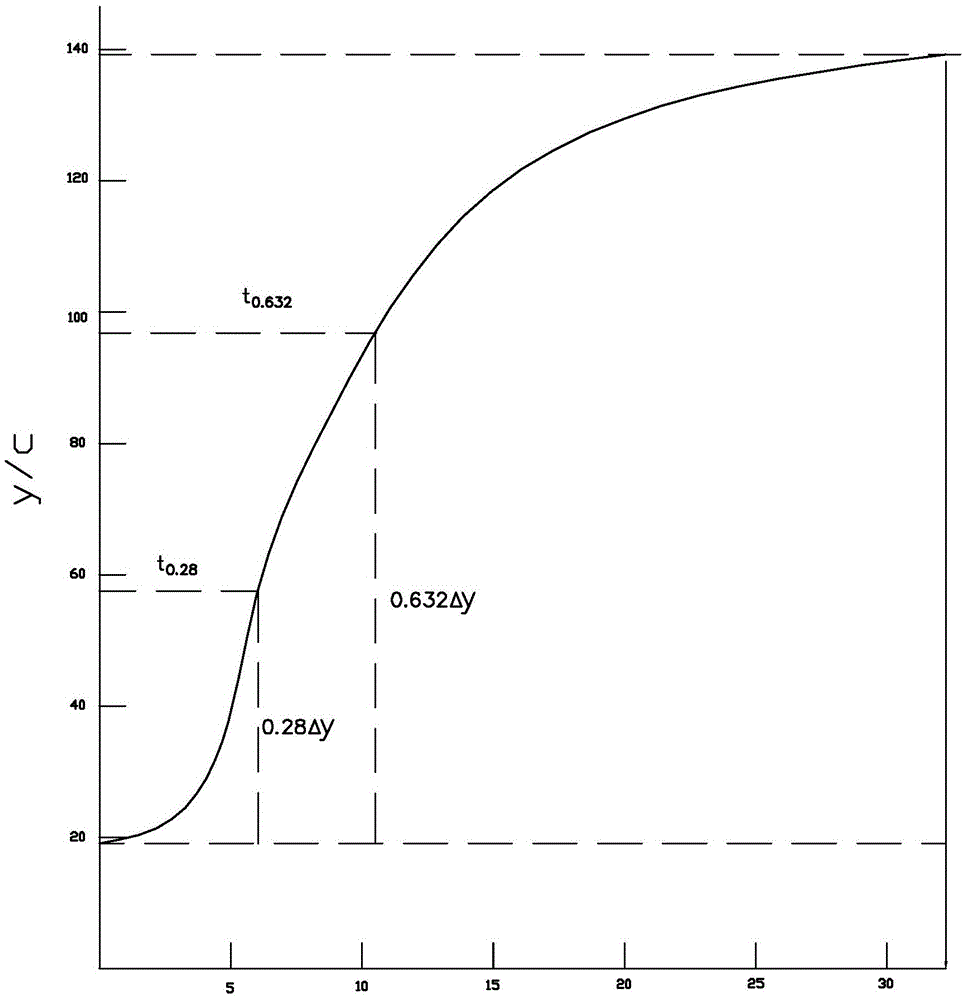

[0094] S1: According to the process control process of the spraying and drying process of the production line, the electric heating device used in the drying process is a resistance heating furnace, and the resistance heating furnace is a controlled object with self-balancing ability. Its mathematical model can be regarded as a first-order inertial link , as shown in the following formula (1):

[0095] (1)

[0096] In the formula: G is the transfer function, and the characteristic parameters K, T, and τ are the inertial link gain, time constant, and pure lag time, respectively;

[0097] S2: Using the experimental method, conduct a power-on test on the resistance heating furnace to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com