Mask for quartz glass acid etching and acid etching method for quart glass pendulous reed

A quartz glass and acid etching technology, applied in the field of acid etching of quartz glass acid etching mask and quartz glass swing piece, can solve the problem of poor batch consistency, high mold processing cost, and difficulty in ensuring the assembly of the pressure plate swing piece Alignment and other issues to achieve the effect of improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

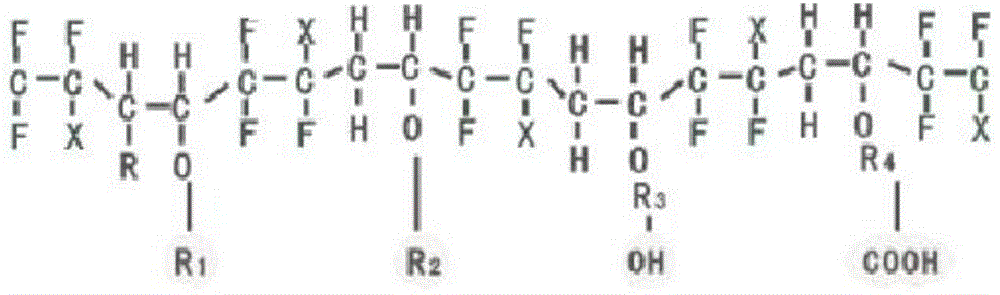

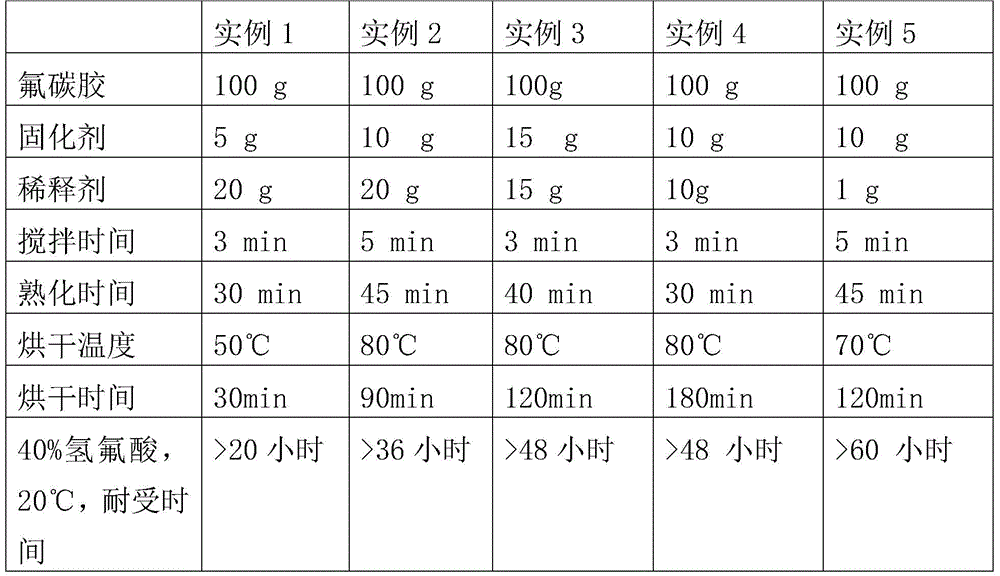

[0026] An embodiment of the present invention proposes a mask for quartz glass acid etching, which uses fluorocarbon glue as a matrix, and adjusts the properties of the glue film by adding 5-15% of the curing agent and 1-20% of the diluent; wherein , The fluorocarbon glue is a polymer obtained by substituting some or all hydrogen atoms in polyethylene or polypropylene with fluorine atoms, and the solid content is greater than 50%. The specific preparation method of the above-mentioned quartz glass acid etching mask is as follows: mixing the fluorocarbon glue, curing agent and diluent, stirring, standing for 30-45 minutes, and discharging the air bubbles in the glue solution. Described curing agent and diluent are used in conjunction with the above-mentioned fluorocarbon glue: curing agent is not only a necessary substance for fluorocarbon paint drying, but also an important component of fluorocarbon glue film-forming substances; the effect of diluent is to adjust the viscosity ...

Embodiment 2

[0036] The embodiment of the present invention also proposes an acid etching method for the flexible beam of the quartz glass swing plate, which mainly includes the steps of mask coating, pattern cutting, heating and curing, etching and stripping.

[0037] The mask coating step is to apply a mask on the surface of the quartz glass substrate, the mask covers the entire surface of the quartz glass substrate, and the mask is used for the above-mentioned quartz glass acid etching. Mask, the coating thickness of the mask on the surface of the quartz glass is 0.05-0.2mm; preferably, first coat the mask on the first surface of the quartz glass substrate, and carry out natural curing; then, on the quartz glass The second surface and sides are coated with a mask, and then cured naturally. The natural curing means that the adhesive film is cured under the action of the curing agent for about 8-10 hours at room temperature. The naturally cured adhesive film is elastic, has weak adhesion ...

example 6

[0043]For the acid etching method of the flexible beam of the quartz glass swing plate, first prepare the mask glue described in Example 1. Clean the glass substrate to remove impurities such as dust and oil, and wipe the substrate with a dust-free cloth. Use the centrifuge homogenizer to coat the mask glue described in Example 1 to the glass substrate. The area of the glass substrate is 380mm 2 , the amount of glue required for each side is 0.05ml; fix the glass substrate on the homogenizer and set it to a slow speed (2-5rad / s), use a straw to suck 0.05ml of mixed glue onto the center of the first surface of the glass substrate, After the mask glue is evenly applied to the outer edge of the substrate, it is removed and cured naturally for 8 hours. Then reconfigure the mask glue described in the above example 1, apply glue to the second surface in the same way, and the glue film is 0.12mm thick. After the mask glue is naturally cured, it can be cut with an ultraviolet las...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com