A kind of method utilizing microreactor to prepare diazonium salt

A technology of microreactor and diazonium salt, which is applied in the direction of organic chemistry, can solve the problem of clogged microchannels, etc., and achieve the effect of continuous process, high raw material utilization rate and excellent mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

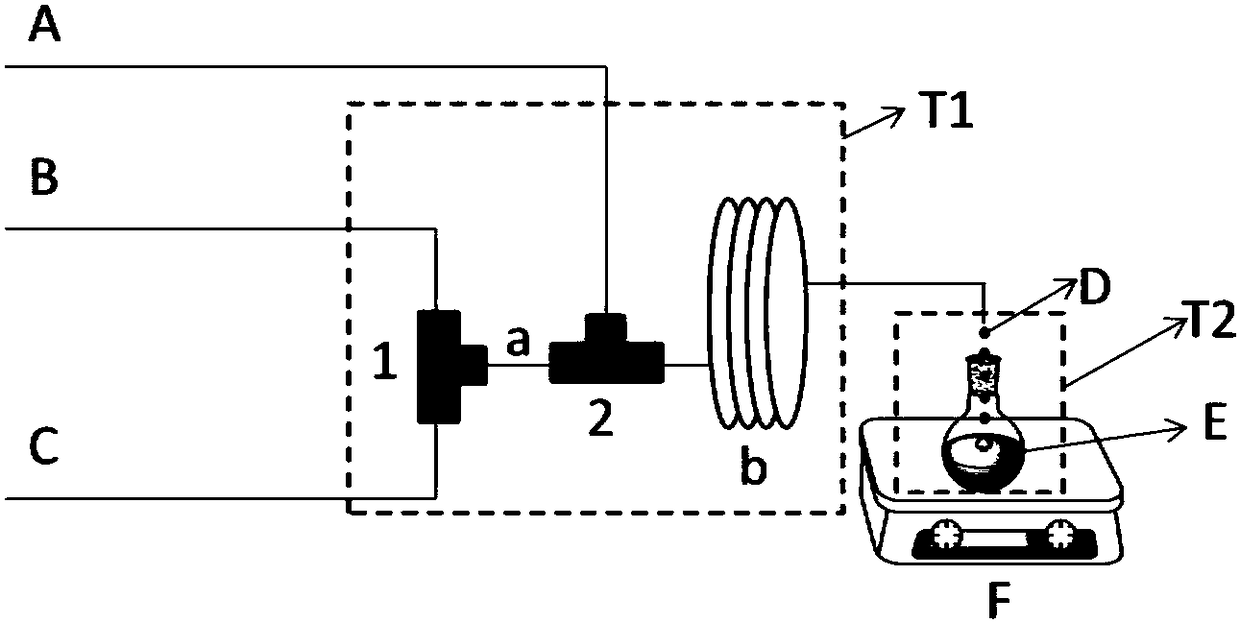

[0023] in such as figure 1In the reaction device shown, the sodium nitrite solution and o-ethylaniline are fed from B and C respectively at a flow rate of 1.1ml / min and 1ml / min (the molar ratio of sodium nitrite and o-ethylaniline is 1:1). The tube is injected into the first micro-mixer 1 (inner interdigitated micro-mixer, SIMM-V2, IMM, Germany, the inner diameter of the mixing channel is 45 μm), and then the mixed solution passes through the first micro-channel a (inner diameter: 0.3 mm, residence time 0.2 s) enter the second micro-mixer 2 (inner diameter 1mm) and the hydrochloric acid injected by feed pipe A at a flow rate of 2.4ml / min (hydrochloric acid and o-ethylaniline molar ratio is 2.8:1) in the constant temperature reaction bath T1 (- 5 ℃), then enter the second microchannel b (inner diameter: 1mm) to continue the reaction for 10s, and the obtained diazonium salt solution is collected with a round-bottomed flask E equipped with potassium iodide, and the round-bottomed...

Embodiment 2

[0025] in such as figure 1 In the reaction device shown, the sodium nitrite solution and o-ethylaniline are fed from B and C at a flow rate of 1.44ml / min and 1ml / min respectively (the molar ratio of sodium nitrite to o-ethylaniline is 1.05:1). The tube is injected into the first micro-mixer 1 (inner interdigitated micro-mixer, SIMM-V2, IMM, Germany, the inner diameter of the mixing channel is 45 μm), and then the mixed solution passes through the first micro-channel a (inner diameter: 0.3 mm, residence time 0.5 s) Enter the second micro-mixer 2 (inner diameter 5mm) and the hydrochloric acid injected from the feed pipe A at a flow rate of 4ml / min (the molar ratio of hydrochloric acid to o-ethylaniline is 3.2:1) in the constant temperature reaction bath T1 (0°C ), and then enter the second microchannel b (inner diameter: 1mm) to continue the reaction for 10s, and the obtained diazonium salt solution is collected with a round-bottomed flask E equipped with potassium iodide, and t...

Embodiment 3

[0027] in such as figure 1 In the reaction device shown, the sodium nitrite solution and o-ethylaniline are fed from B and C respectively at a flow rate of 1.44ml / min and 1ml / min (the molar ratio of sodium nitrite to o-ethylaniline is 1.1:1). The tube is injected into the first micromixer 1 (interdigital micromixer, SIMM-V2, IMM, Germany, the inner diameter of the mixing channel is 45 μm), and then the mixed solution passes through the first microchannel a (0.3mm, residence time 0.5s) Enter the second micro-mixer 2 (inner diameter 9mm) and the hydrochloric acid injected from the feed pipe A at a flow rate of 4ml / min (the molar ratio of hydrochloric acid to o-ethylaniline is 4:1) in the constant temperature reaction bath T1 (40°C) Mix, then enter the second microchannel b (inner diameter: 1mm) to continue the reaction for 2s, and the obtained diazonium salt solution is collected with a round-bottomed flask E equipped with potassium iodide, and the round-bottomed flask E is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com