A kind of preparation method of high molecular weight poly(methylethyl-methylvinyl)siloxane

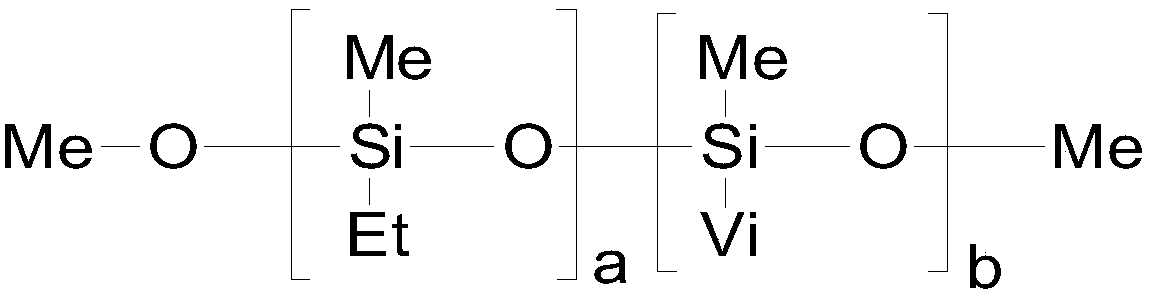

A technology of tetramethyltetravinylcyclotetrasiloxane and tetramethyltetraethylcyclotetrasiloxane, which is applied in the field of polysiloxane preparation, can solve the complex preparation process and the ring-opening rate of comonomers different, harsh reaction conditions, etc., to achieve the effect of simple polymerization process, low glass transition temperature, and controllable molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

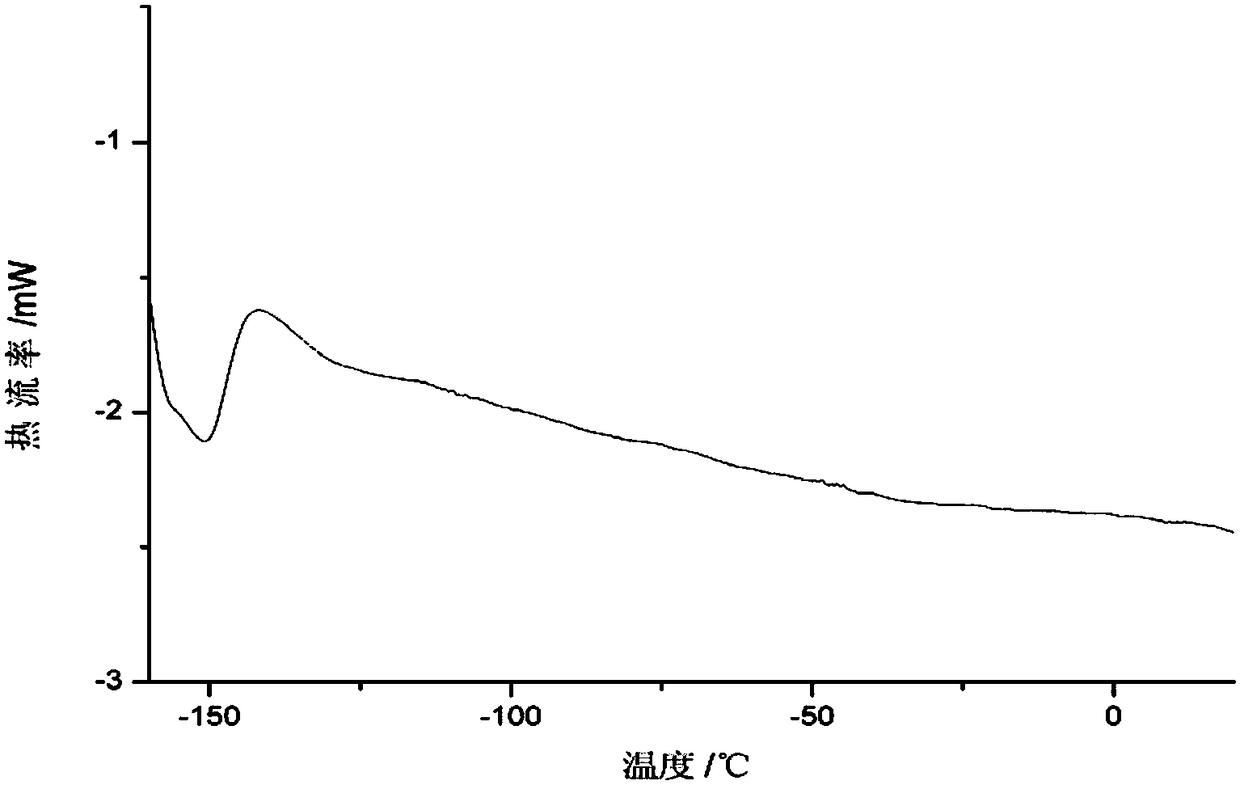

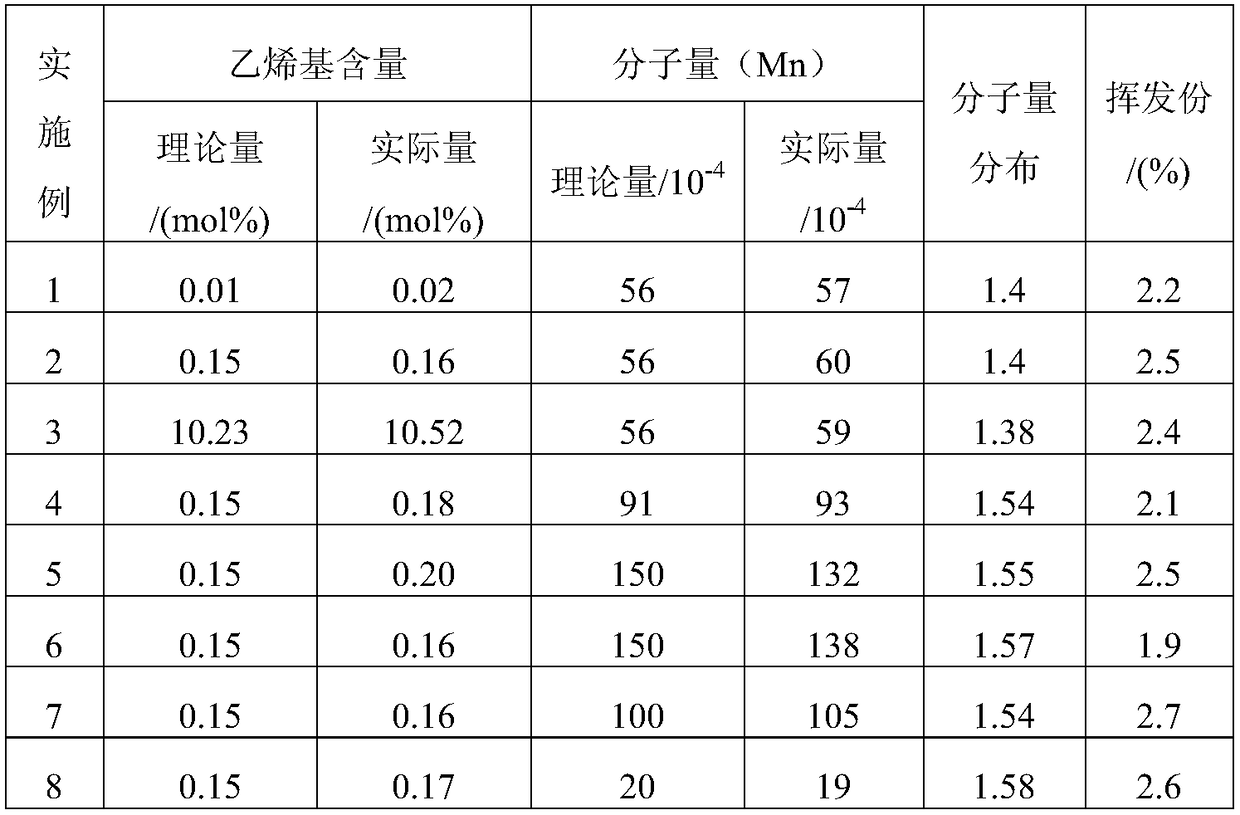

Embodiment 1

[0028] 200g tetramethyltetraethylcyclotetrasiloxane (D 4 Me,Et ), 0.02g tetramethyltetravinylcyclotetrasiloxane (D 4 Vi ) and 0.169g of octamethyltrisiloxane were added to the 2 In the reactor with conduit and thermometer, dehydrate at 60°C for 2h under reduced pressure, then blow dry nitrogen and raise the temperature to 130°C, add 2.00g of potassium hydroxide silicon alkoxide to start polymerization, and react for 2h. After the polymerization reaction is completed, continue to heat up to 200°C, remove small molecular low boilers in the material under the condition of a vacuum degree of less than or equal to 100Pa, for 1h, cool to room temperature and discharge, and obtain high molecular weight poly(methylethyl) - methylvinyl) siloxane. Measure the vinyl content, molecular weight and its distribution and volatile content of the product, and the results are listed in Table 1; the DSC of high molecular weight poly(methyl ethyl-methyl vinyl)siloxane is listed in figure 1 . ...

Embodiment 2

[0031] 200g tetramethyltetraethylcyclotetrasiloxane (D 4 Me,Et ), 0.293g tetramethyltetravinylcyclotetrasiloxane (D 4 Vi ) and 0.169g of octamethyltrisiloxane were added to the 2In the reactor with conduit and thermometer, dehydrate at 60°C for 2h under reduced pressure, then blow dry nitrogen and raise the temperature to 130°C, add 2.00g of potassium hydroxide silicon alkoxide to start polymerization, and react for 2h. After the polymerization reaction is completed, continue to heat up to 200°C, remove small molecular low boilers in the material under the condition of a vacuum degree of less than or equal to 100Pa, for 1h, cool to room temperature and discharge, and obtain high molecular weight poly(methylethyl) - methylvinyl) siloxane. The vinyl content, molecular weight and its distribution and volatile content of the product were measured, and the results are listed in Table 1.

Embodiment 3

[0033] 200g tetramethyltetraethylcyclotetrasiloxane (D 4 Me,Et ), 20g tetramethyltetravinylcyclotetrasiloxane (D 4 Vi ) and 0.169g of octamethyltrisiloxane were added to the 2 In the reactor with conduit and thermometer, dehydrate at 60°C for 2h under reduced pressure, then blow dry nitrogen and raise the temperature to 130°C, add 2.00g of potassium hydroxide silicon alkoxide to start polymerization, and react for 2h. After the polymerization reaction is completed, continue to heat up to 200°C, remove small molecular low boilers in the material under the condition of a vacuum degree of less than or equal to 100Pa, for 1h, cool to room temperature and discharge, and obtain high molecular weight poly(methylethyl) - methylvinyl) siloxane. The vinyl content, molecular weight and its distribution and volatile content of the product were measured, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com