All-biological-based resin composition

A technology of base resin and composition, applied in the field of full bio-based resin composition, can solve the problems that are not involved in hydrolysis resistance, destructive biodegradability, overall performance defects, etc., and achieve superior biodegradation performance, high toughness and Effects of hydrolysis resistance and high hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of bio-based carbodiimide (the proportion of bio-polyols is 54%), the specific steps are as follows:

[0026] Add 200 grams of StabaxolP220 polycarbodiimide (a tetramethylxylylene diisocyanate produced by Rhine Chemical, with an NCN content of about 14%) to the nitrogen environment, and add 238 grams of Agrol2 when heated to 140 ° C .0 bio-based polyol (a bio-based polyol with an OH number of 74.5 produced by Cargrill), start stirring the mixture, monitor the NCO content in the mixture until the NCO content drops to zero, and the reaction is completed to obtain bio-polyols 54% bio-based carbodiimide.

Embodiment 1

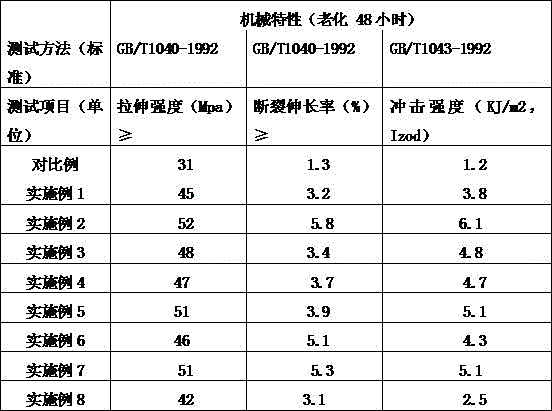

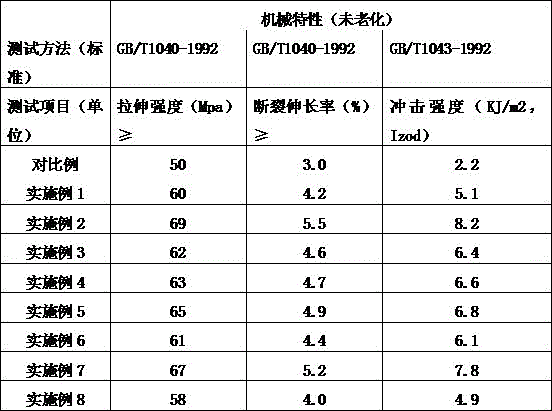

[0028] An all-bio-based resin composition, proportioned according to the weight of the following components: 100 parts of polylactic acid (Hisun Biomaterials REVODE190), 2 parts of bio-based carbodiimide (54% of bio-polyols) , 5 parts of talc powder (3000 mesh), 2 parts of polycaprolactone; put the well-proportioned mixture in a twin-screw extruder for blending and granulation, and the temperature settings of each section of the screw are: 190°C, 200°C, 210°C, 220°C, 205°C, speed: 50rpm, after granulation, put it in the injection molding machine for injection molding, the injection temperature is 205°C, the injection pressure is 100mpa, the cooling time of the melt in the mold is 38 seconds, the mold temperature Set at 100°C to obtain a fully bio-based resin composition. The mechanical properties and hydrolysis resistance of the composition were tested, and the results are shown in Table 1 and Table 2.

Embodiment 2

[0030]The full bio-based resin composition is proportioned according to the weight of the following components: 100 parts of polylactic acid (Hisun Biomaterials REVODE190), 2 parts of bio-based carbodiimide (54% of bio-polyols), talcum powder (3000 mesh) 5 parts, polybutylene succinate 10 parts; put the well-proportioned mixture in a twin-screw extruder for blending and granulation, and the temperature settings of each section of the screw are: 190 ° C, 200 ° C , 210°C, 220°C, 205°C, speed: 50rpm, after granulation, put it in the injection molding machine for injection molding, the injection temperature is 205°C, the injection pressure is 100mpa, the cooling time of the melt in the mold is 38 seconds, the mold The temperature was set at 100° C. to obtain a fully bio-based resin composition. The mechanical properties and hydrolysis resistance of the composition were tested, and the results are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com