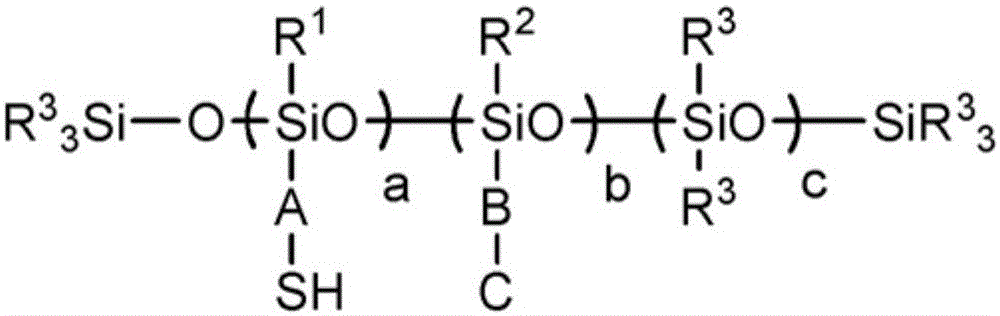

Fluorine-containing composition for surface treatment of porous base material

A technology for surface treatment and porous substrates, which is applied in biocide-containing paints, coatings, antifouling/underwater coatings, etc., and can solve the problems of limited adhesion between polymers and substrates, and easy gradual loss of effect. Achieve ideal adhesion effect, good three-proof effect, and good anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

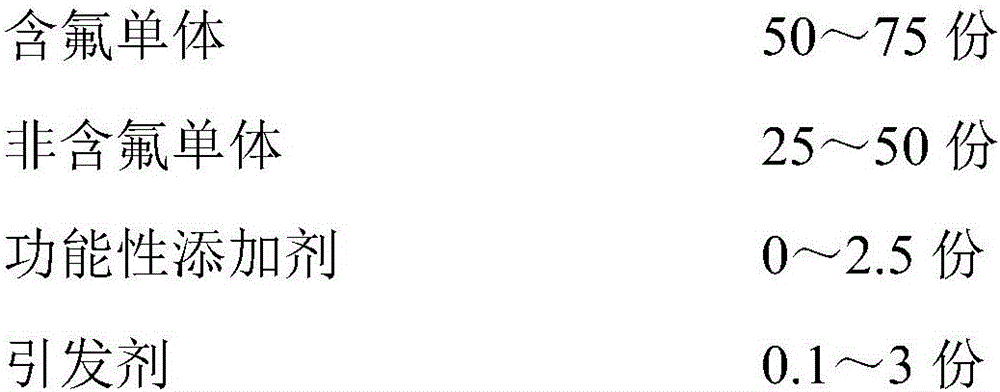

Method used

Image

Examples

Synthetic example 1

[0202] Monomer CH 2 =CHCOOCH 2 CH 2 NHCOOCH 2 CH 2 CF 2 CF 2 CF 2 CF 2 CF 2 CF 3 Synthesis of - F3

[0203] Add 364g (1mol) of C2 to a 1L four-necked reaction flask equipped with a stirrer, a constant temperature oil bath, a thermometer and a condenser, and add 141g (1mol) of D1 dropwise under normal temperature and stirring conditions. A small amount of hydroquinone inhibitor, then heated to 80°C for 8 hours to obtain a light yellow transparent liquid. Infrared analysis showed that the absorption peak of the isocyanate group disappeared completely.

Synthetic example 2

[0205] Monomer CH 2 =C(CH 3 ) COOCH 2 CF(CF 3 )[OCF 2 CF(CF 3 )] p OCF 2 CF 2 CF 3 Synthesis of , p represents the number of repeating units, and the average value of p is 5.3——F4

[0206] Add 1196g (1mol) of C3, 95g (1.1mol) of D2, an appropriate amount of water-carrying agent and a small amount of hydroquinone polymerization inhibitor in a 1L four-necked reaction flask equipped with a stirrer, a constant temperature oil bath, a thermometer and a condenser With a small amount of p-toluenesulfonic acid catalyst, the temperature is raised to 120° C. for esterification under stirring. When the water in the water separator is close to the theoretical value, the esterification is complete. Then, the water-carrying agent and unreacted methacrylic acid are removed by atmospheric distillation and vacuum distillation respectively, and then the catalyst and polymerization inhibitor are removed by washing with water, and the target product is obtained by vacuum drying.

Synthetic example 3

[0208] Monomer CH 2 =CHCOOCH 2 CH 2 NHCOONHCH 2 CH 2 NHCH 2 CH 2 CH 2 Si(OCH 3 ) 3 Synthesis of - S3

[0209] Add 222g (1mol) of B4 into a 1L four-necked reaction flask equipped with a stirrer, a constant temperature oil bath, a thermometer and a condenser, and add 141g (1mol) of D1 dropwise under normal temperature and stirring conditions. A small amount of hydroquinone (purchased from Nanjing Xinhuayuan Chemical Co., Ltd.) as a polymerization inhibitor was heated to 80° C. for 8 hours to obtain a light yellow transparent liquid. Infrared analysis showed that the absorption peak of the isocyanate group disappeared completely.

[0210] The synthesis of fluoropolymers is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com