Method for preparing titanium-based graphene composite material through 3D printing technology

A graphene composite and 3D printing technology, applied in the field of composite materials, achieves the effects of high preparation efficiency, simple preparation process, and convenient experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

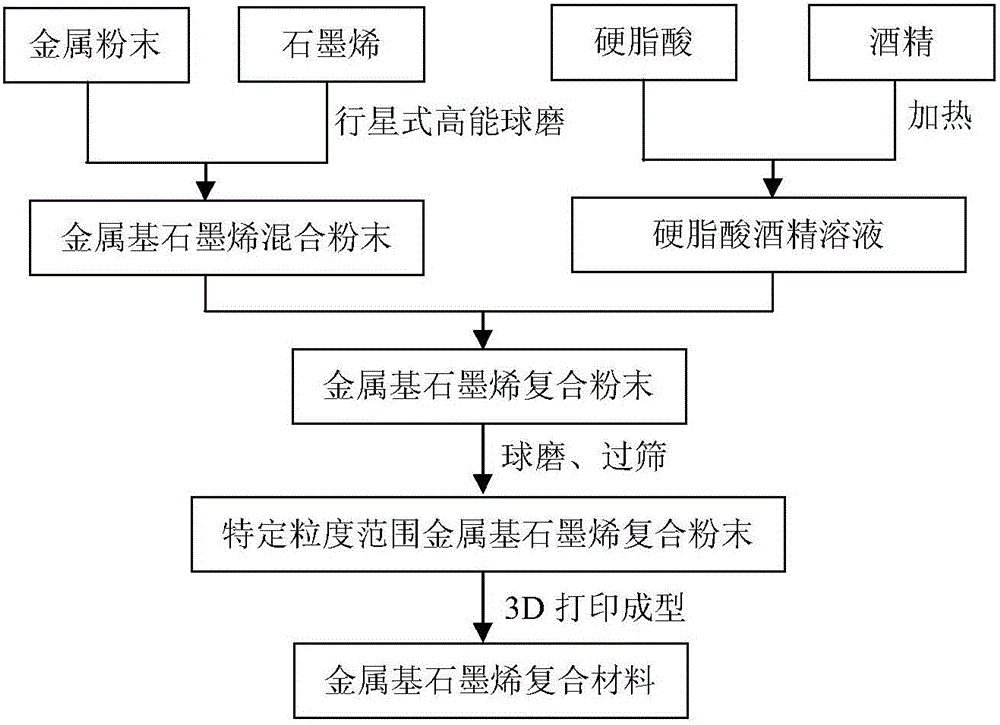

Method used

Image

Examples

Embodiment 1

[0022] Take 100g of titanium powder (average particle size 20μm) and 1.0g of graphene (multilayer graphene, thickness 20nm), and put them together into a planetary high-energy ball mill for ball milling. The speed of the ball mill is 200rpm, stop for 20min every 1h, and then reverse for 1h Stop for 20 minutes, a total of 3 cycles, wherein the ball milling medium is WC cemented carbide balls, and the ball-to-material ratio is 4:1, thereby obtaining titanium-based graphene mixed powder.

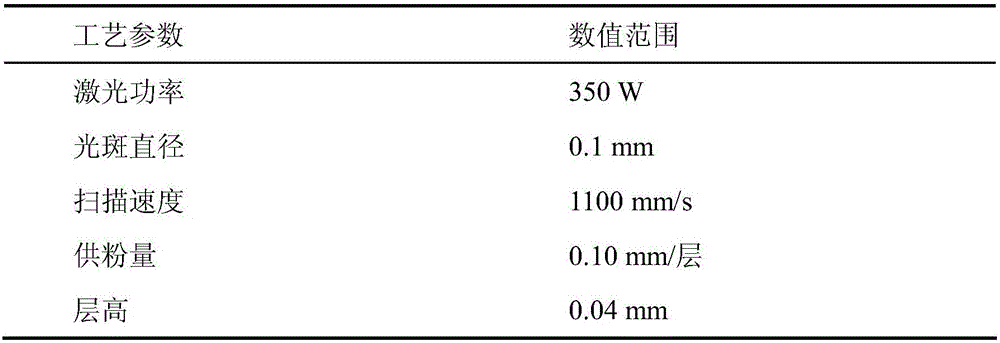

[0023] Get 1g of stearic acid and add it to 10ml of alcohol heated to 60°C to obtain a stearic acid alcohol solution. Add the stearic acid alcohol solution into the titanium-based graphene mixed powder, and ball mill it again at a speed of 200 rpm for 5 minutes, pass the titanium-based graphene mixed powder through a 200-mesh sieve to obtain a titanium-based graphene mixed powder with an average particle size of 20 μm . Put the mixed powder into the powder supply box in batches, and wipe the s...

Embodiment 2

[0029] Take 100g of titanium powder (average particle size 40 μm) and 0.1g of graphene (multilayer graphene, thickness 15nm), put them together into a planetary high-energy ball mill for ball milling, and the ball mill speed is 100rpm. Every ball mill for 1 hour, stop for 20 minutes, then reverse for 1 hour, stop for 20 minutes is a cycle, a total of 2 cycles, in which the ball milling medium is WC cemented carbide balls, and the ball-to-material ratio is 4:1, so as to obtain titanium-based graphene mixed powder.

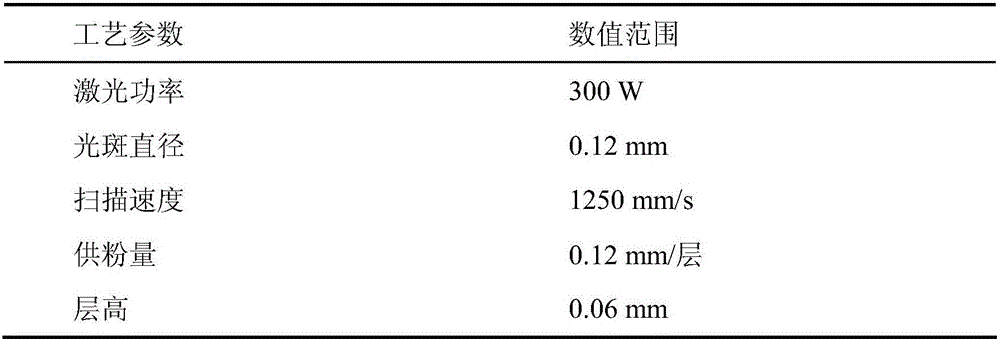

[0030] Get 0.5g stearic acid and add in 10ml alcohol heated to 60 ℃, obtain stearic acid alcohol solution. Add the stearic acid alcohol solution into the titanium-based graphene mixed powder, and ball mill it again at a speed of 200 rpm for 5 minutes, pass the titanium-based graphene mixed powder through a 200-mesh sieve to obtain a titanium-based graphene mixed powder with an average particle size of 40 μm . Put the mixed powder into the powder supply box in batch...

Embodiment 3

[0036] Get 100g titanium powder (average particle diameter 60 μ m) and 3g graphene (multilayer graphene, thickness 20nm), put into the ball mill together in the planetary high-energy ball mill, the ball mill rotating speed is 300rpm. Milling for 1 hour, stopping for 20 minutes, reversing for 1 hour, stopping for 20 minutes is a cycle, a total of 4 cycles, wherein the ball milling medium is WC cemented carbide balls, and the ball-to-material ratio is 4:1, so as to obtain titanium-based graphene mixed powder.

[0037] Get 3g stearic acid and add in the 10ml alcohol that is heated to 60 ℃, obtain stearic acid alcoholic solution. Add the stearic acid alcohol solution into the titanium-based graphene mixed powder, and ball mill it again at a speed of 200 rpm for 5 minutes, pass the titanium-based graphene mixed powder through a 200-mesh sieve to obtain a titanium-based graphene mixed powder with an average particle size of 60 μm . Put the mixed powder into the powder supply box in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com