Additive manufacturing method for electrical contact made of copper-tungsten functionally gradient material

A functionally graded material, additive manufacturing technology, applied in metal material coating process, circuits, electrical switches, etc., can solve problems such as poor high-voltage breaking capacity and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

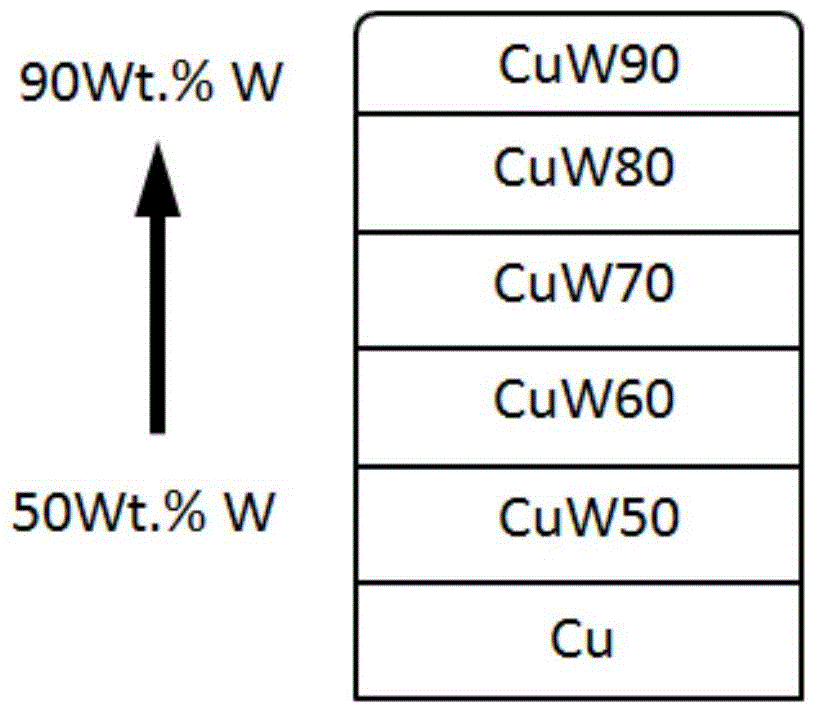

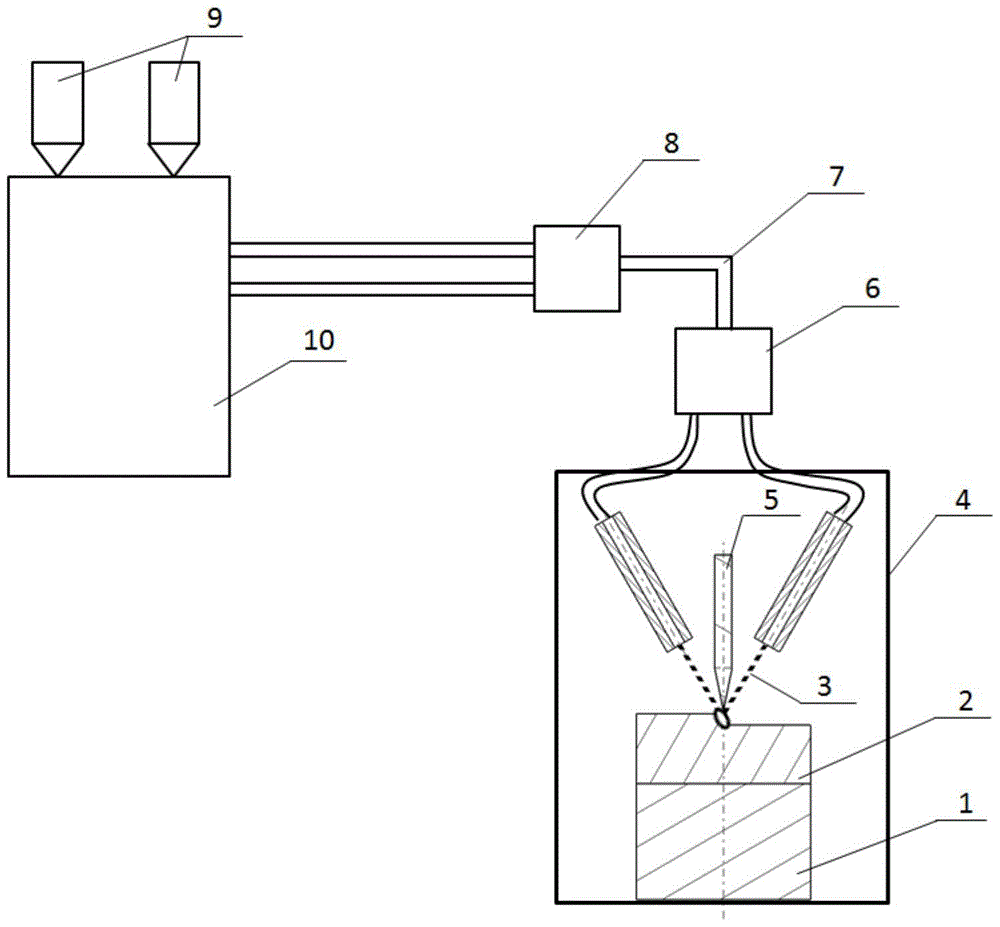

[0020] refer to Figure 1-Figure 2 , the copper powder and tungsten powder in the two powder feeding cylinders 9 of the double-barrel powder feeder 10 are conveyed through the powder feeding pipe 7, and the conveyed copper powder and tungsten powder are firstly mixed by the powder mixer 8 and then After passing through the powder separator 6, it is divided into 4 to 8 paths of powder flow. In the process of additively manufacturing copper-tungsten gradient materials, the high-energy beam 5 melts and deposits a mixed powder of copper powder and tungsten powder on the copper substrate 1 in the atmosphere protection studio 4; the gas punched in the atmosphere protection studio 4 can It is nitrogen or argon, and its purpose is to prevent oxidation of copper-tungsten functionally graded material electrical contacts manufactured by additiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com