Micro-arc oxidation reaction device

A reaction device and micro-arc oxidation technology, applied in anodizing, surface reaction electrolytic coating, coating, etc., can solve problems such as damage to personnel and equipment, waste of materials, cumbersome process, etc., to avoid the danger of electric shock and avoid the danger of electric shock , the effect of avoiding the danger of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

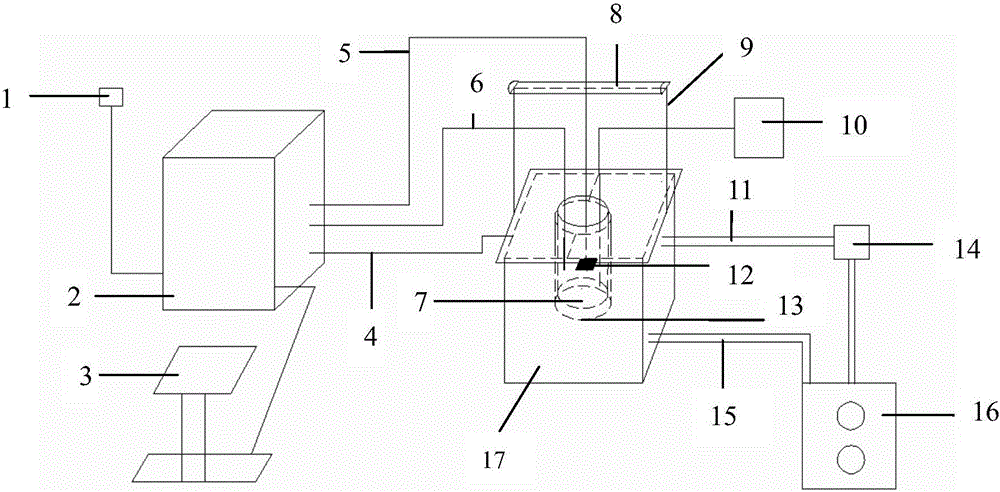

[0024] refer to Figure 1 to Figure 3 , a micro-arc oxidation reaction device, including a cooling unit 16, a power supply connection line 1, a power supply 2, a numerical control table 3, a cooling water tank 17 and a stainless steel electrolytic cell 13 fixed in the cooling water tank 17 for holding an electrolyte, the described Stainless steel electrolyzer 13 connects the negative electrode 4 of power supply 2; The upper end of described cooling water tank 17 is provided with cooling water outlet 11, and the lower end is provided with cooling water inlet 15, and described cooling water outlet 11, cooling water inlet 15 are respectively connected with described The cooling unit 16 is connected, and a circulating pump 14 is set between the cooling water outlet and the cooling unit; the numerical control platform 3 is used to control the opening and closing of the cooling unit 16; it also includes a safety protection device;

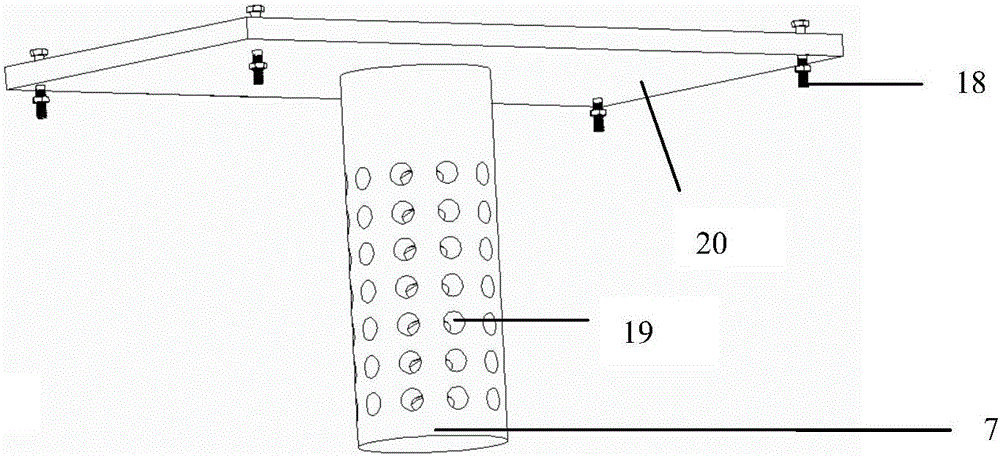

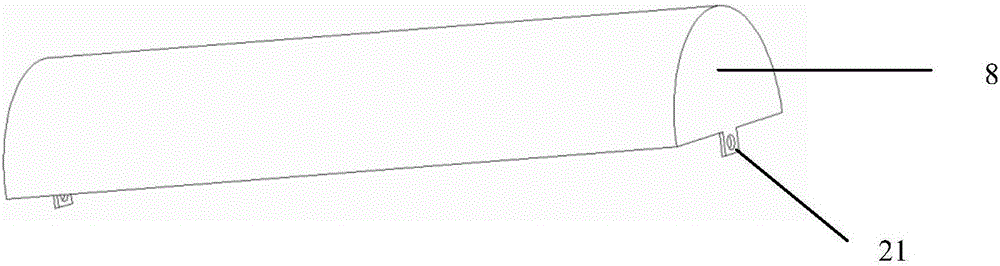

[0025] The safety protection device includes a buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com