Singeing machine capable of feeding cloth by balanced tensile force

A technology of singeing machine and tension balance, which is applied in singeing, textile and papermaking, and fabric surface trimming, etc. It can solve the problems of color difference and color flower that cannot be improved, and achieve the effect of solving color difference, improving fabric quality and widening market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

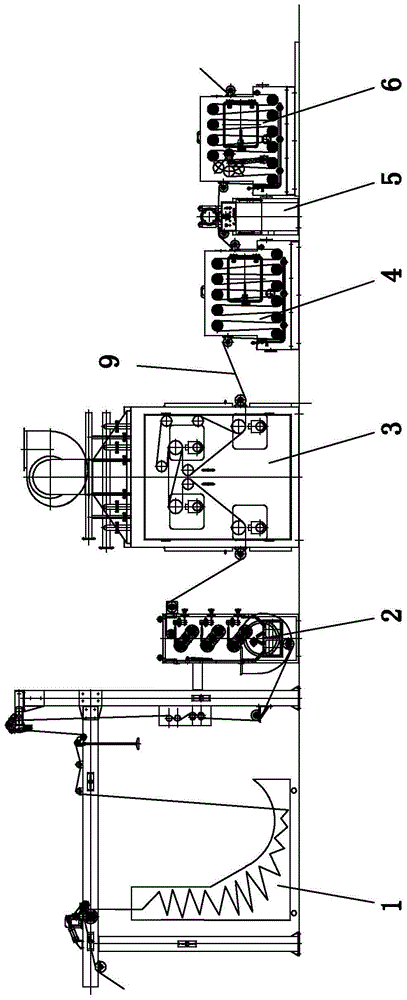

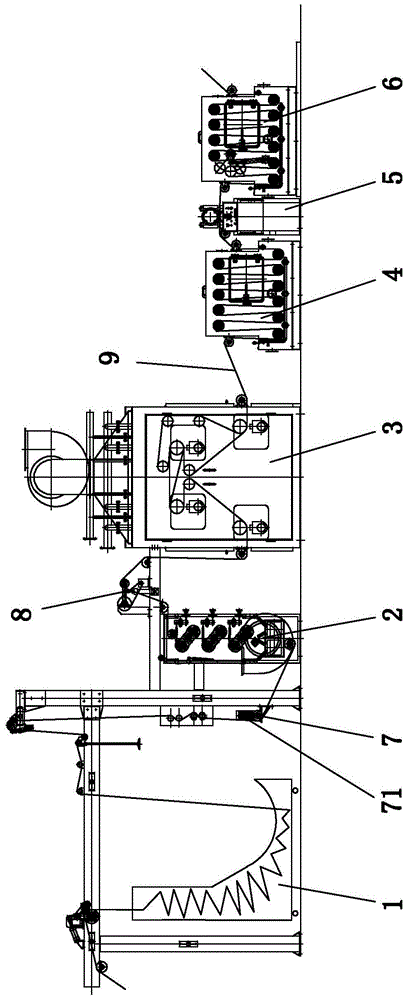

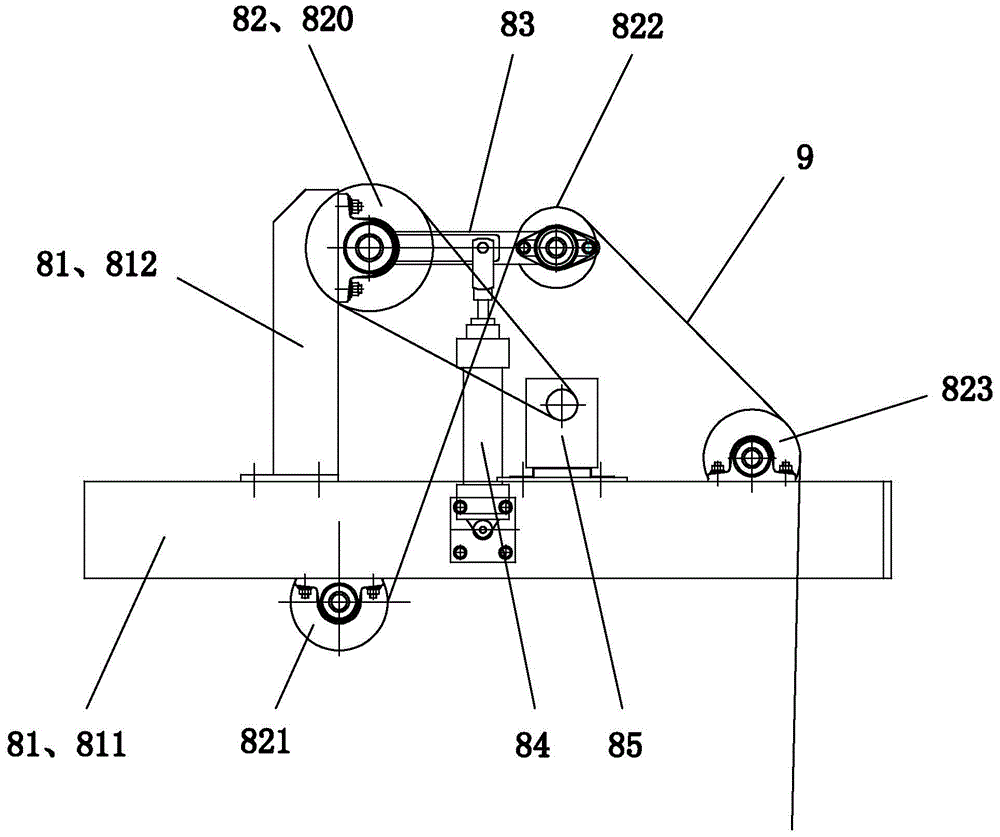

[0020] The structure of the singeing machine of the balanced tension feeding cloth of the present embodiment is shown in figure 2 , including a cloth storage box 1, an active cloth feeding roller 7 driven by a geared motor 71, a bristle box 2, an automatic tension adjustment device 8, a singeing box 3, a washing box 4, a traction paddle car 5 and an oven 6.

[0021] The motor speed of the traction rolling car 5 is 1440 revs / min, the reduction ratio is 13: 1, and the diameter of the outer circle of the roll is 290mm. The surface linear speed of the traction rolling car=3.14×290×(1440 / 13) / 1000=100.87 m / min.

[0022] The rotating speed of the reduction motor 71 on the active cloth feeding roller 7 is 1410 revs / min, the reduction ratio is 7.5: 1, and the outer diameter of the active cloth feeding roller 7 is 172mm. The surface linear velocity of the active cloth feeding roller 7=3.14×172×(1410 / 7.5) / 1000=101.53 m / min.

[0023] The difference between the two surface linear speeds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com