In-situ polymerization modified graphene and polyester composite chip as well as preparation method and application thereof

A technology of in-situ polymerization and graphene, which is applied in the manufacture of rayon, textiles and paper, single-component polyester rayon, etc., can solve the problems that polyester slices do not have functionality and cannot meet the requirements of functional textiles, and achieve In-situ polymerized graphene polyester composite slice uniformity, anti-ultraviolet performance, and good functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

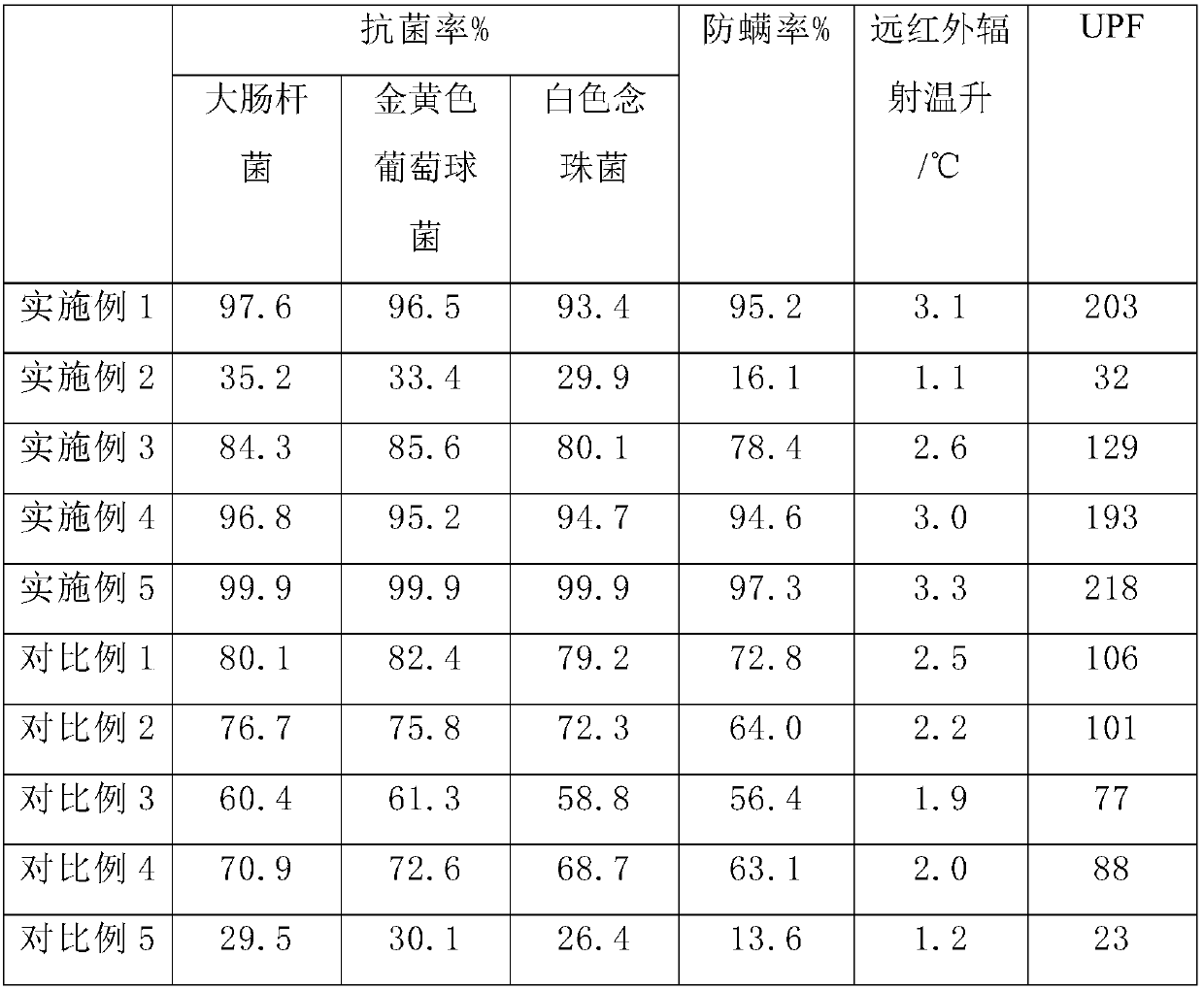

Examples

Embodiment 1

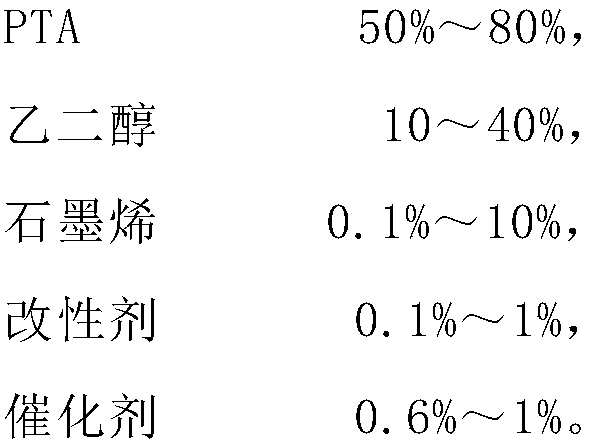

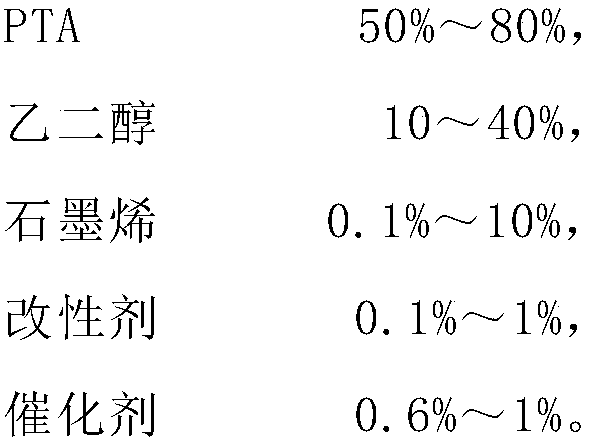

[0027] This embodiment provides a method for preparing in-situ polymerized modified graphene polyester composite chips, the contents of each component are shown in Table 1, and the specific preparation steps are as follows:

[0028] Step 1: Preparation of modified GO / EG slurry, graphene oxide is slowly added to a certain amount of ethylene glycol, and at the same time mixed modifiers (polyethylene glycol, polyvinylpyrrolidone, sodium lauryl sulfate and Hexadecyltrimethylammonium bromide, the weight ratio is 1:1:2:5) into the GO / EG slurry, stir and mix evenly, raise the temperature to 50-80°C, and treat for 10-20min. The modified GO / EG dispersion solution was obtained.

[0029] Step 2: PTA / EG / modified GO slurry is prepared, the prepared modified GO / EG dispersion solution is placed under a mechanical stirrer and stirred, and a certain amount of catalyst (antimony trioxide, antimony ethylene glycol, the ratio is 1:0.2) into the slurry, and continue beating for 0.5-1h to obtain a...

Embodiment 2

[0034] This embodiment provides a method for preparing in-situ polymerized modified graphene polyester composite chips, the contents of each component are shown in Table 1, and the specific preparation steps are as follows:

[0035] Step 1: Preparation of modified GO / EG slurry, graphene oxide is slowly added to a certain amount of ethylene glycol, and at the same time mixed modifiers (polyethylene glycol, polyvinylpyrrolidone, sodium lauryl sulfate and Hexadecyltrimethylammonium bromide, the weight ratio is 1:1:3:4) into the GO / EG slurry, stir and mix evenly, raise the temperature to 50-80°C, and treat for 10-20min. The modified GO / EG dispersion solution was obtained.

[0036] Step 2: PTA / EG / modified GO slurry is prepared, the prepared modified GO / EG dispersion solution is placed under a mechanical stirrer and stirred, and a certain amount of catalyst (antimony trioxide, antimony ethylene glycol, the ratio is 1:0.4) into the slurry, and continue beating for 0.5-1h to obtain a...

Embodiment 3

[0041] This embodiment provides a method for preparing in-situ polymerized modified graphene polyester composite chips, the contents of each component are shown in Table 1, and the specific preparation steps are as follows:

[0042] Step 1: Preparation of modified GO / EG slurry, graphene oxide is slowly added to a certain amount of ethylene glycol, and at the same time mixed modifiers (polyethylene glycol, polyvinylpyrrolidone, sodium lauryl sulfate and Hexadecyltrimethylammonium bromide, the weight ratio is 1:1:2.5:6) into the GO / EG slurry, stir and mix evenly, raise the temperature to 50-80°C, and treat for 10-20min, The modified GO / EG dispersion solution was obtained.

[0043]Step 2: PTA / EG / modified GO slurry is prepared, the prepared modified GO / EG dispersion solution is placed under a mechanical stirrer and stirred, and a certain amount of catalyst (antimony trioxide, antimony ethylene glycol, the ratio is 1:0.5) into the slurry, and continue beating for 0.5-1h to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com