Application of triamine base substituted phenol or triamine base substituted thiophenol and micro-etching treating fluid

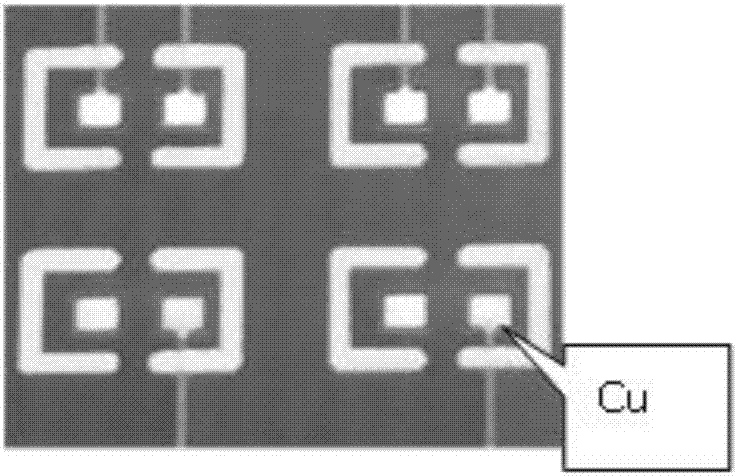

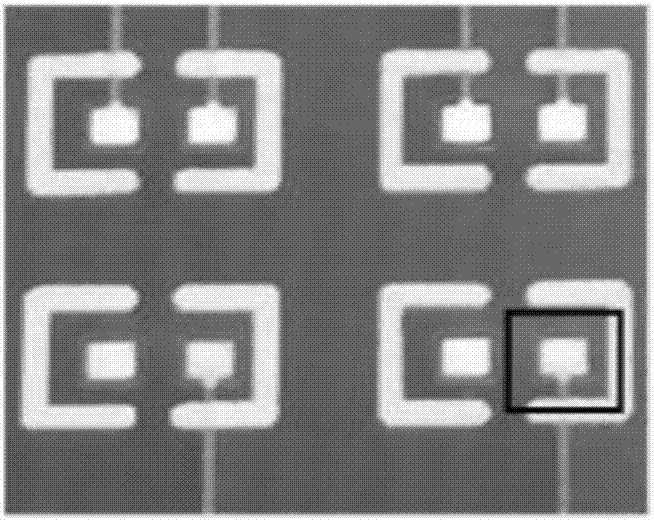

A technology of micro-etching treatment and thiophenol, which is applied in the application of triamine-substituted phenol or triamine-substituted thiophenol and the field of micro-etching treatment liquid, can solve the problem of rough appearance of copper surface, accelerated corrosion rate of copper surface, Problems such as the reduction of copper pad area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

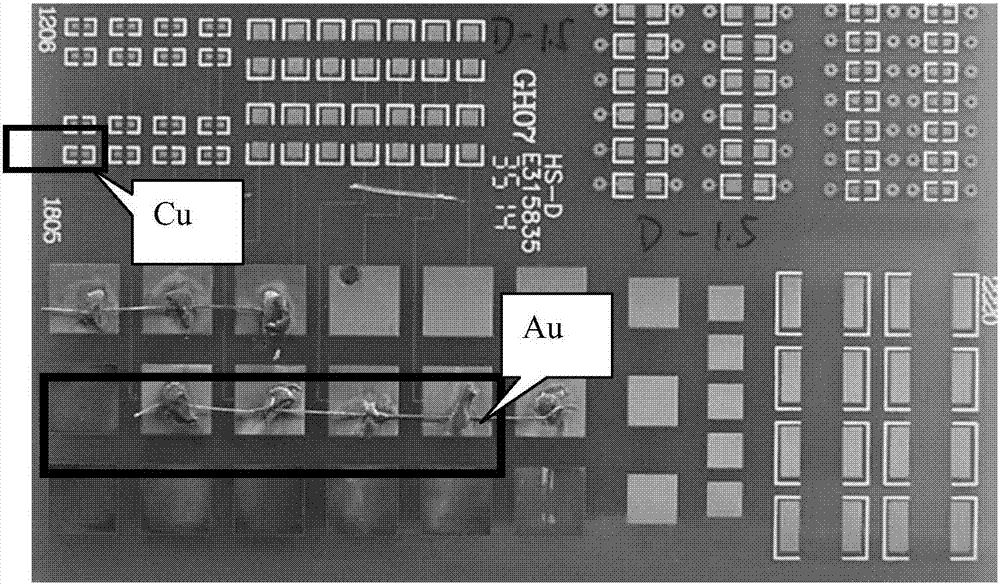

[0050] Embodiment 1: According to the normal PCB production process, a copper-gold mixed board is prepared. The ratio of the area of the gold surface to the area of the copper surface is 500:1. Each micro-etching time is 1 minute, and the micro-etching amount is 1.0-1.5 μm. After different times of micro-etching, the reduction ratio of the copper area connected to the gold surface is tested. During the test, it is necessary to adjust the concentration of hydrogen peroxide in the solution to ensure that the microetching solution of the embodiment of the present invention and the microetching solution of the comparative example have the same microetching rate on the copper clad laminate (not connected to the gold surface).

Embodiment approach 2

[0051] Embodiment 2: Prepare a copper-gold mixed board, the ratio of the area of the gold surface to the area of the copper surface is 500:1, and it is processed through the following process:

[0052] Degreasing cleaning - washing - micro-etching - washing - OSP - washing - drying.

[0053] Among them, the acid degreasing agent TS-Acidclean 6151 of Dongshuo Company is used for degreasing and cleaning (a mature product of Dongshuo Company, which has been widely used by customers. Its function is to clean the copper surface and remove stains, fingerprints and oils on the copper surface. and other pollutants, provide a clean copper surface for the subsequent operation), the operating temperature is 40°C, and the treatment time is 1 minute; the microetching solution of the present invention is used for microetching, and its effect is to micro-roughen the copper surface, and the operating temperature is 30°C , the processing time is 1 minute, and the amount of microetching is ...

Embodiment 1

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com