Novel wood-based composite material

A composite material and wood-based technology, applied in the field of materials, can solve the problems of reducing the application range of wood materials, increasing the intermediate links, easy to crack, etc., and achieving the effects of stable growth stress and not easy deformation, increased support strength, and increased elastic strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

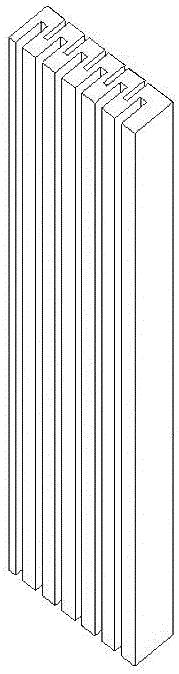

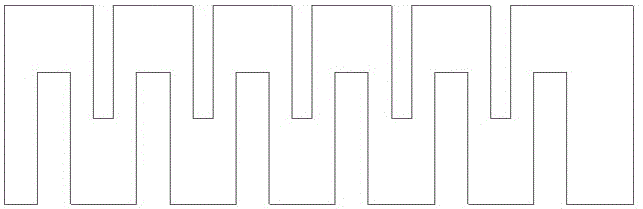

[0059] This embodiment is a commonly used solid wood sawn timber in the wood processing industry. It is processed by longitudinal sawing of logs to make boards and squares with a certain cross-sectional size or cross-sectional size. Planks or squares are the most common and widely used It is also a raw material for processing other wood products. The plank in this embodiment refers to plank or sawn longitudinally along the heart of the tree and along the growth direction of the wood as the basis of the composite material, as a solid wood material directly processed from the log, and has been dried.

[0060] The specific structure is composed of figure 1 As shown, the cross section of the plate is rectangular, the two sides with longer sides are used as the upper surface and the lower surface of the plate, and the two sides with shorter sides are used as the left and right sides. For the artificial depression that destroys the growth stress processed by woodworking saws, that ...

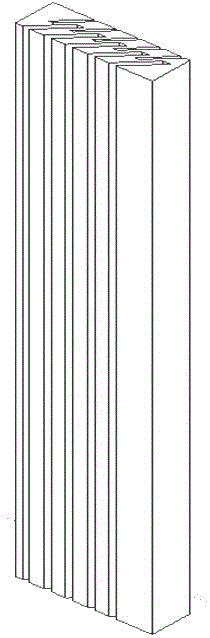

Embodiment 2

[0064] The base material of this embodiment 2 is the same as that of embodiment 1, and the purpose of destroying the growth stress of the wood itself is achieved by processing artificial depressions on the board.

[0065] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that in order to achieve the same purpose of eliminating the growth stress of trees, several holes can also be processed on the plate, and these holes can be unpenetrated on one side, or can be It is not pierced on both sides, or it can be a hole that penetrates both sides. The shape of the hole can be circular, elliptical, and other shapes such as rhombus and polygon. A common hole is a deep hole perpendicular to the side of the solid wood sawn timber, and the deep hole does not penetrate the solid wood sawn timber laterally; the described hole may be a through hole perpendicular to the side of the solid wood sawn timber, and the through hole runs through the solid wood s...

Embodiment 3

[0069] Embodiment 3 is a further improvement on the basis of Embodiment 1 and Embodiment 2. Specifically, the time-delayed setting material or the quick-setting material is filled and coated on the wooden board processed with wire grooves. That is, by filling the linear grooves with materials such as calcium carbonate and adhesives, the gaps are cured to form a more stable shape, reducing deformation and increasing overall stability.

[0070] The time-delayed solidification material in the embodiment can be cement, also can calcium carbonate add adhesive, or diatom ooze, polyurethane foaming agent, glass cement etc., their common feature is that flow state is first, waits to be filled and painted slowly Slow solidification, so as to enhance the strength of the base material, as a new type of wood-based composite material.

[0071] In production practice, the base material can be soft wood such as pine, poplar, fir, etc., and after the growth stress is destroyed by slotting, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com