A two-degree-of-freedom measuring device and method based on plane mirror imaging

A technology of measuring devices and measuring methods, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of complex principles, cumbersome calculation processes, high procurement and maintenance costs, and achieve strong survivability, small external interference, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

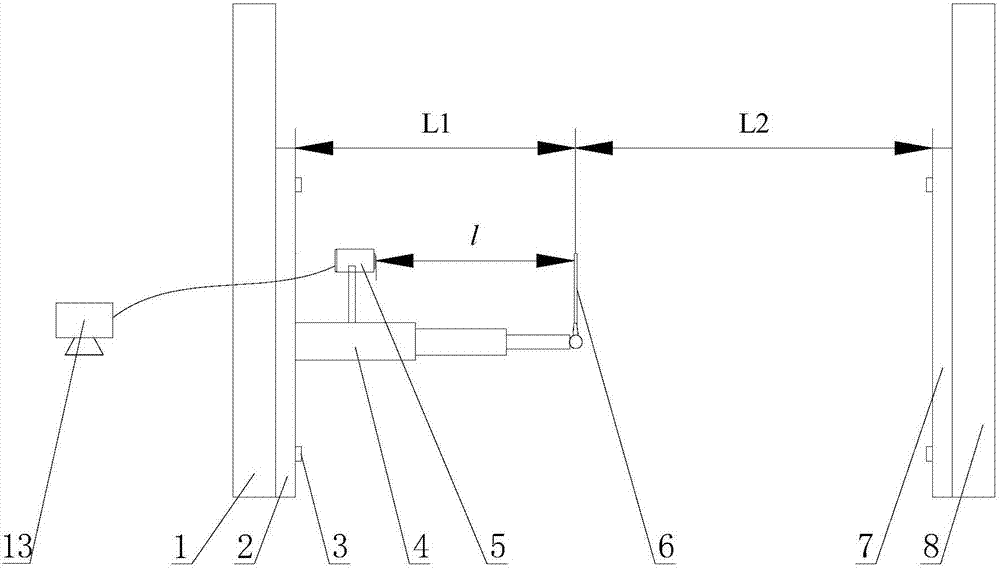

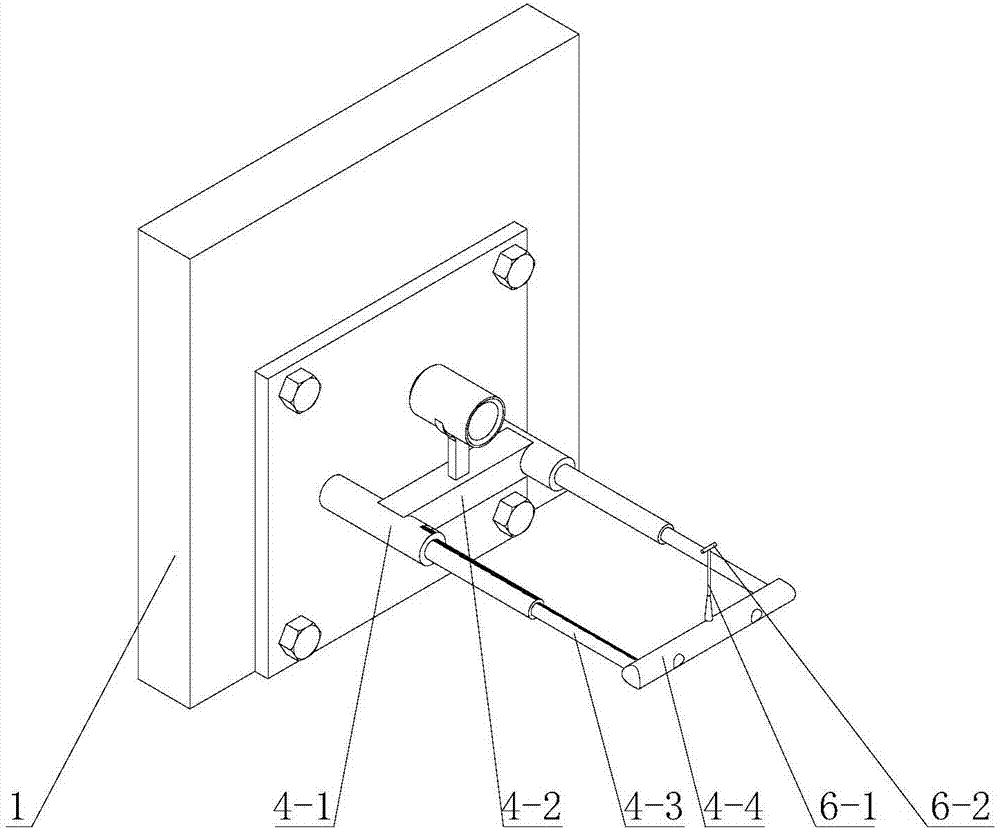

[0039] Now take the measurement of two degrees of freedom between hydraulic supports as an example, such as figure 1 and 2 As shown, the two-degree-of-freedom measuring device based on plane mirror imaging of the present embodiment is composed of a reference fixed plate 1, a reference plane mirror 2, a fastening connection bolt 3, a camera 5, a mirror frame 4, a horizontal marking rod 6-2, and a longitudinal marking rod 6-1. The fixed plate 8 to be tested, the plane mirror 7 to be tested and the computer 13 are composed.

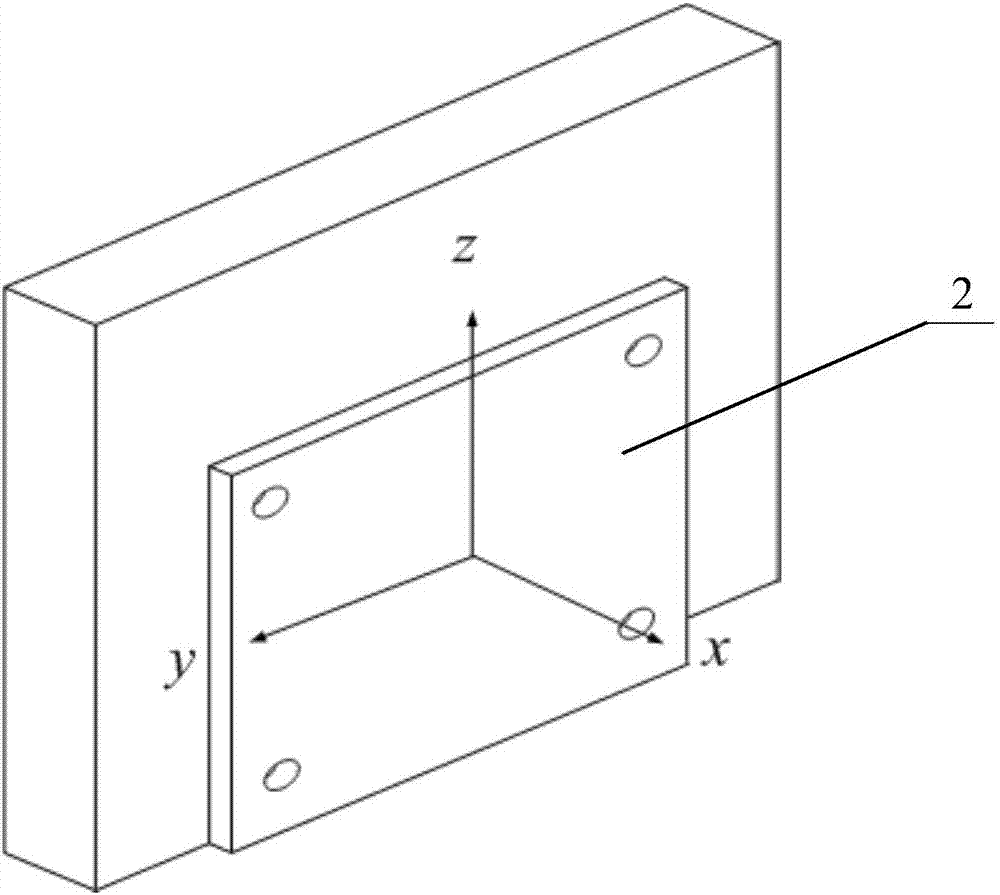

[0040] Specifically: the reference fixed plate 1 of the present embodiment is a rectangular plate structure, which is used to install the reference flat mirror 2, that is, a rectangular reference flat mirror 2 is installed in the middle part of the reference fixed plate 1, as a measurement reference, on the reference flat mirror 2 The four corners are fastened with fastening bolts 3 and the reference fixed plate 1. Two mounting holes are provided in the mid...

Embodiment 2

[0056] see Figure 8 , the reference fixed plate 1 and the reference plane mirror 2 of the present embodiment, the fixed plate 8 to be measured and the plane mirror 7 to be measured are all fastened by the U-shaped fixing frame 9, that is, the fastening connecting bolt 3 is replaced by the U-shaped fixing frame 9, and the reference The fixed plate 1 is fastened to the reference plane mirror 2, and the fixed plate 8 to be tested is fastened to the plane mirror 7 to be tested. The fixing method of this embodiment is suitable for situations where the site is open and the installation space is large.

[0057] The U-shaped fixed mount 9 of the present embodiment comprises a first U-shaped fixed mount 9 and a second U-shaped fixed mount 9, the first U-shaped fixed mount 9 is used to fix the reference fixed plate 1 and the reference plane mirror 2, and the second U-shaped fixed mount 9 The frame 9 is used to fix the fixed plate 8 to be tested and the flat mirror 7 to be tested, see ...

Embodiment 3

[0062] see Figure 10 , the reference fixed plate 1 and the reference plane mirror 2 of the present embodiment, the fixed plate 8 to be measured and the plane mirror 7 to be measured are all fastened by the double-headed suction cup frame 10, that is, replace the fastening connecting bolt 3 with the double-headed suction cup frame 10, and the reference The fixed plate 1 is fastened to the reference plane mirror 2, and the fixed plate 8 to be tested is fastened to the plane mirror 7 to be tested. The fixing method of this embodiment does not need to drill holes and does not damage the hydraulic support.

[0063] There are 8 double-head suction cup holders 10 in this embodiment, which are divided into two groups, and are respectively distributed on the four corners of the reference plane mirror 2 and the plane mirror 7 to be measured. see Figure 11 and 12 , the double-headed suction cup frame 10 of the present embodiment is made of suction cup 10-1, spring 10-2, intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com