A method for measuring light softening of an azobenzene thin film through utilization of surface wrinkling

A light softening and azobenzene technology, which is applied in the field of mechanical performance testing of azobenzene films, can solve the problems of large differences in measurement results, and achieve the effect of simple operation, good repeatability and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

[0018] A kind of method that utilizes surface wrinkle to measure light softening of azobenzene film that the present invention proposes comprises the following steps:

[0019] (1) After mixing the PDMS prepolymer and cross-linking agent at a mass ratio of 10:1, stir fully to form a uniform prepolymer, degas the prepolymer in a vacuum pump, pour it into a petri dish, and heat it at 80°C Heating to crosslink.

[0020] (2) Fix the PDMS elastomer obtained by crosslinking in step (1) on the stretching platform, and stretch according to the pre-stretch ratio of 5%;

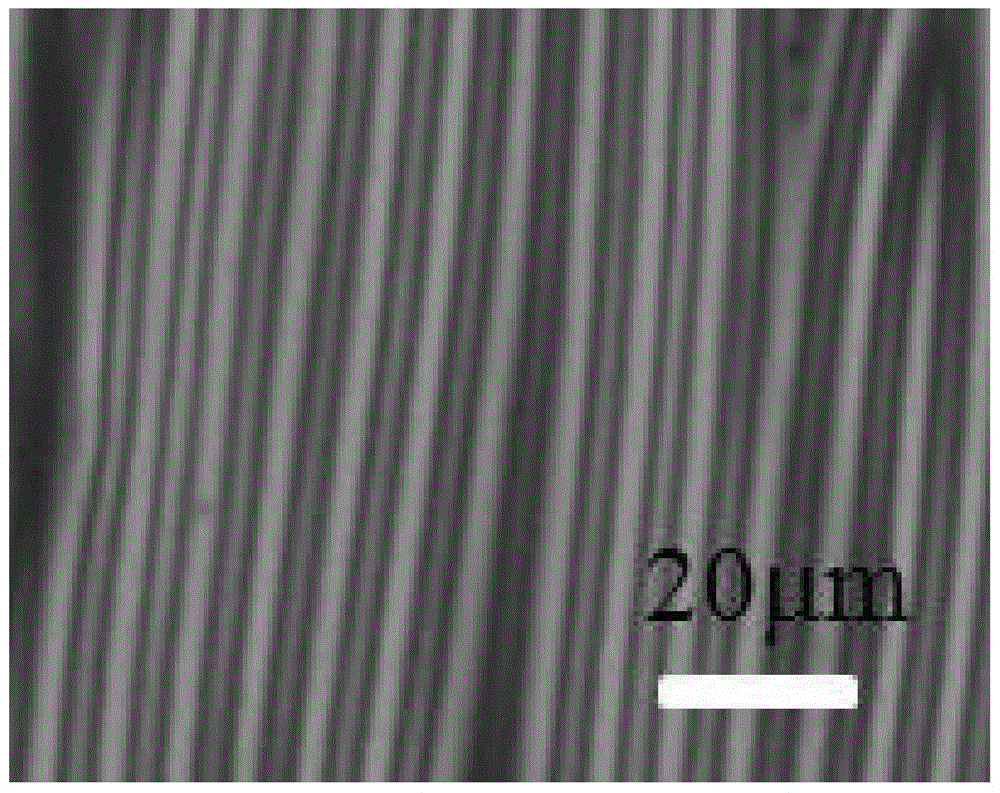

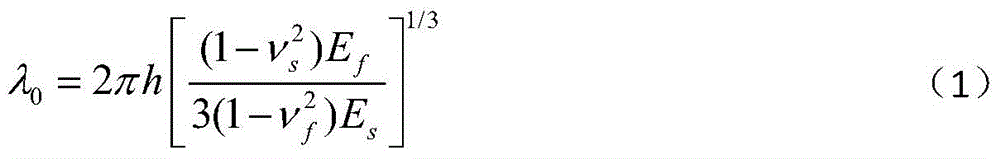

[0021] (3) Spin-coat a tetrahydrofuran solution with a mass fraction of 2wt% PAzo on a clean glass substrate, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com