Area-array giant-magnetoresistance magnetic sensor and manufacturing method thereof

A technology of a magnetic sensor and a manufacturing method, applied in the field of sensing and detection, can solve the problems of low integration, limited use environment and application scope of the sensor, etc., and achieve the effects of high accuracy, space-saving arrangement, and easy processing and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

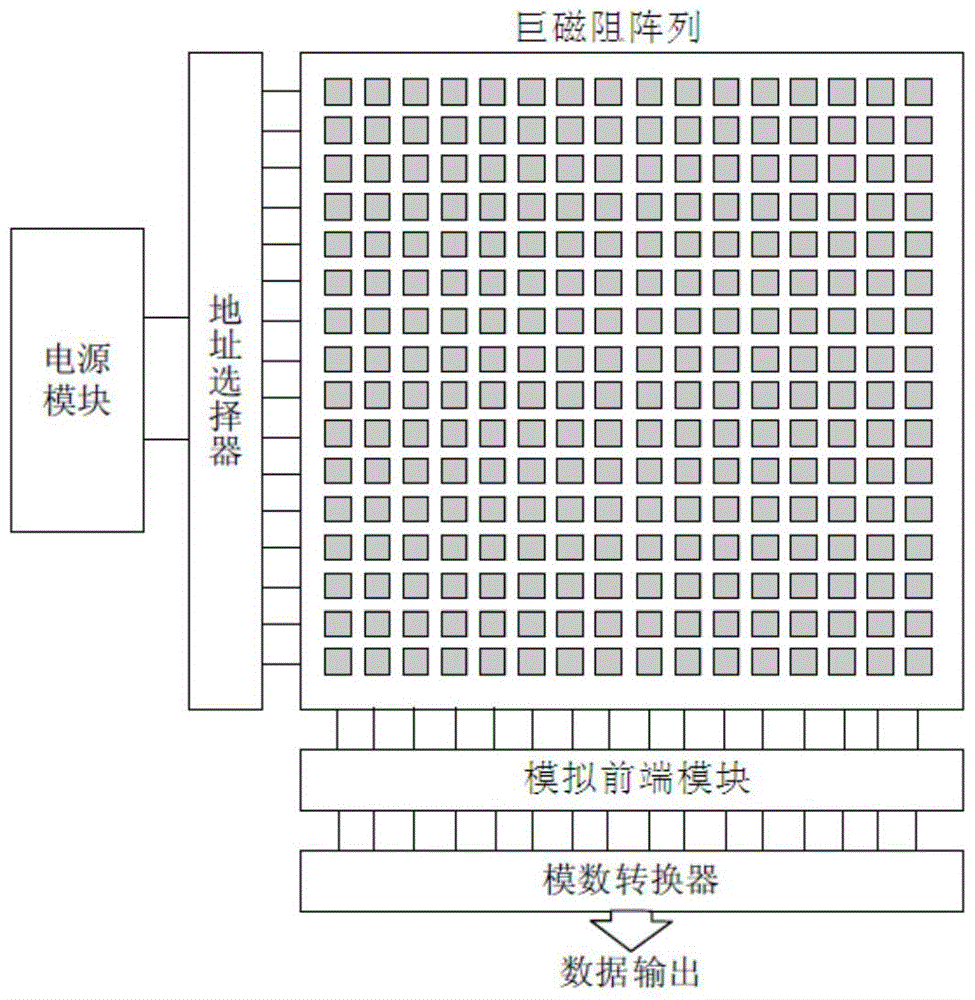

[0032] The invention provides an area array giant magnetoresistive magnetic sensor, which uses a giant magnetoresistance array to detect the magnetic field on the entire surface, and outputs quickly in a row scanning manner.

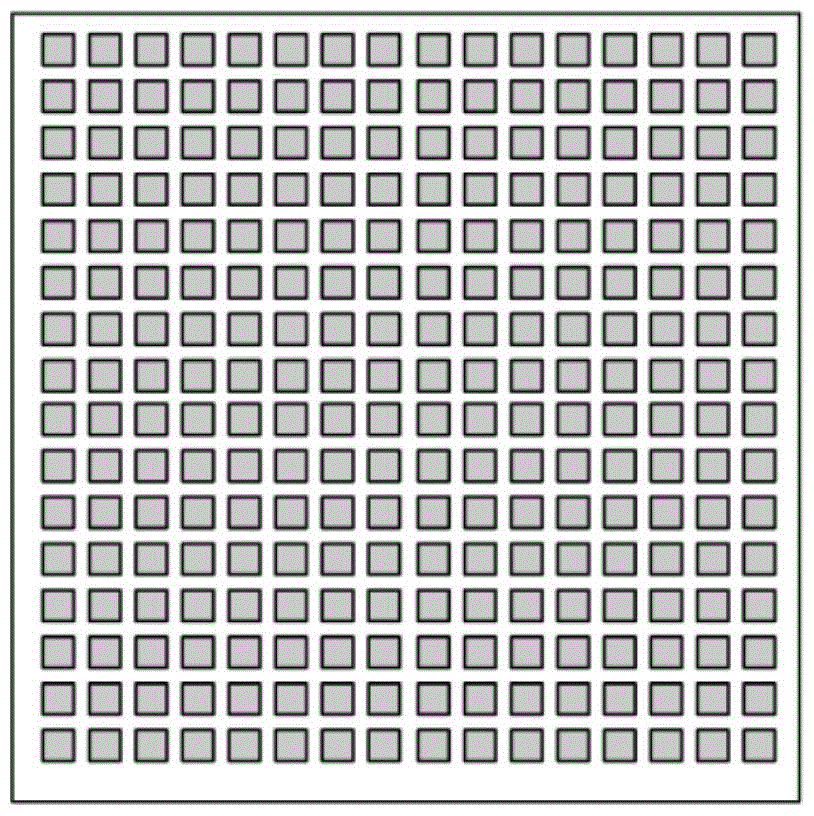

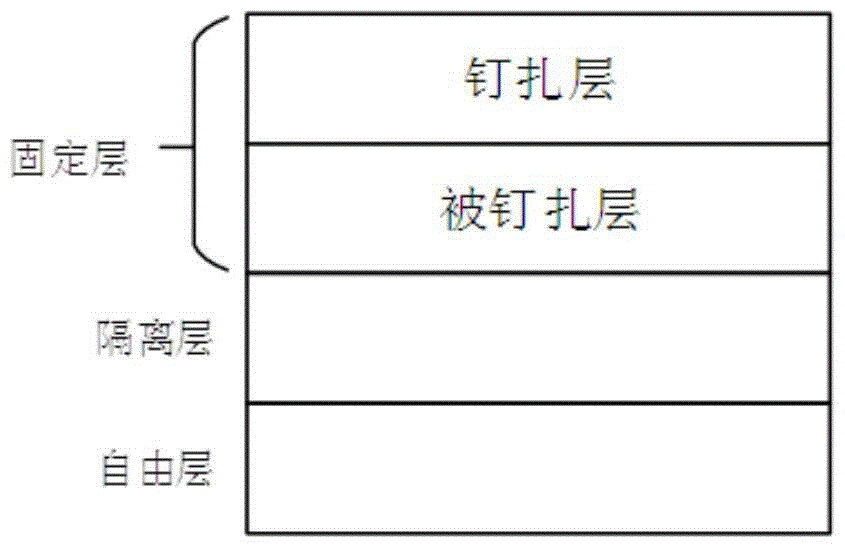

[0033] see figure 1 and figure 2 As shown, the invention discloses an area array giant magnetoresistive magnetic sensor, which includes a giant magnetoresistance array, a power supply module, an address selector, an analog front-end module and an analog-to-digital converter. The giant magnetoresistive array consists of 256 spin valve giant magnetoresistive units in the form of a 16*16 area array, and each unit is designed as a meandering resistance; the power supply module provides input voltage signals for the entire system; the address selector is mainly composed of Composed of row decoders, the function is to output the signals of 16 giant magnetoresistive array elements row by row in row scanning mode; the analog front-end performs signal amplifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com