Nanometre spraying device and method thereof for realizing high-load CPU enhanced heat dissipation function

A spray device and high-load technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of easy scaling or blockage, large pressure loss, and high requirements, so as to reduce demand, increase thermal conductivity, and ensure safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

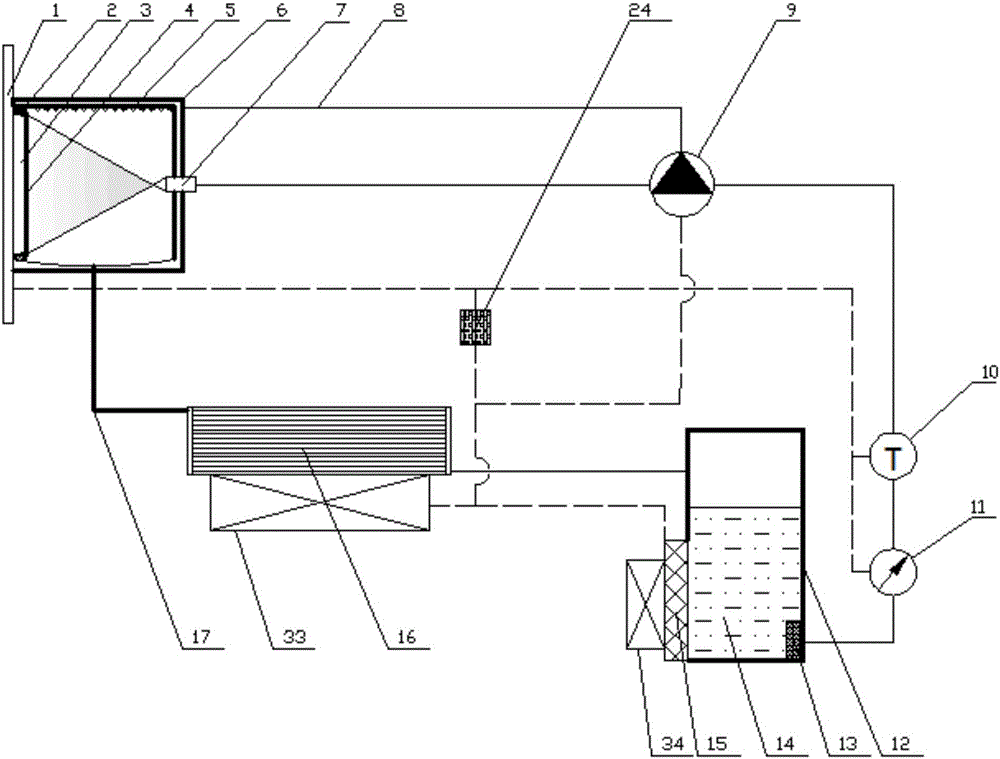

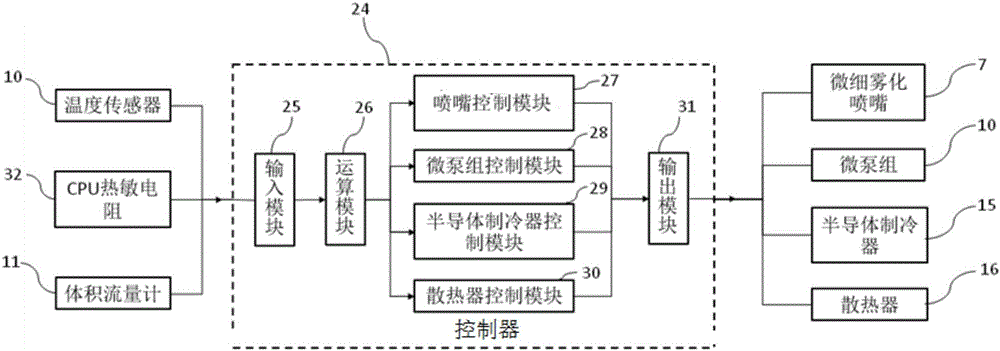

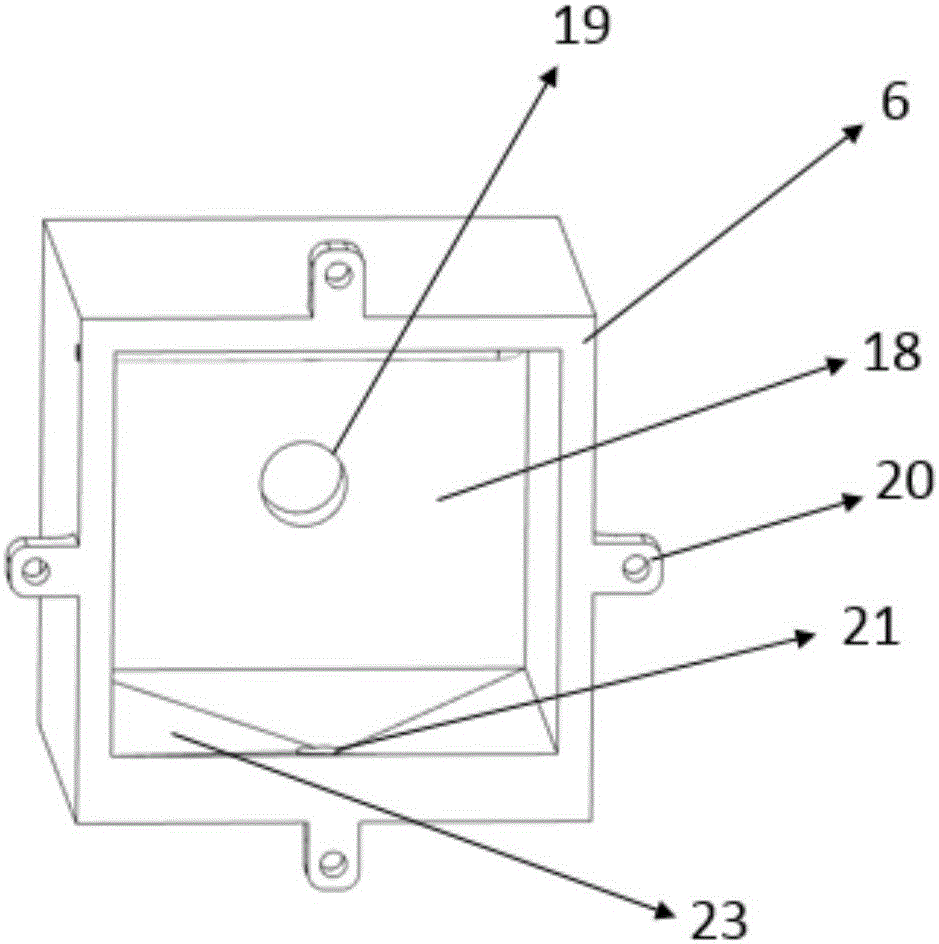

[0038] figure 1 and figure 2Shown is an embodiment of the nano-spray device for realizing the high-load CPU enhanced heat dissipation function of the present invention, and the nano-spray device for realizing the high-load CPU enhanced heat dissipation function includes a PCB circuit board 1, a CPU 3, and a thin copper sheet 4 , condensation pipe 5, spray chamber 6, coolant tank 12, filter 13, coolant 14, effect mechanism and controller 24. By spraying the coolant mist onto the surface of the CPU3, film boiling heat transfer and forced convection heat transfer are formed to realize efficient heat dissipation of the CPU3.

[0039] The effect mechanism includes a nozzle 7, a micropump group 9, a radiator 16 and a semiconductor refrigerator 15;

[0040] The CPU3 is located on the PCB circuit board 1, and the upper surface of the CPU3 is closely attached to the thin copper sheet 4 through a layer of extremely thin and evenly thick high-temperature insulating heat-conducting glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com