Nano-structural lipid carrier pharmaceutical composition and preparation method thereof

A technology of nanostructured lipids and compositions, applied in drug combinations, liposome delivery, pharmaceutical formulations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

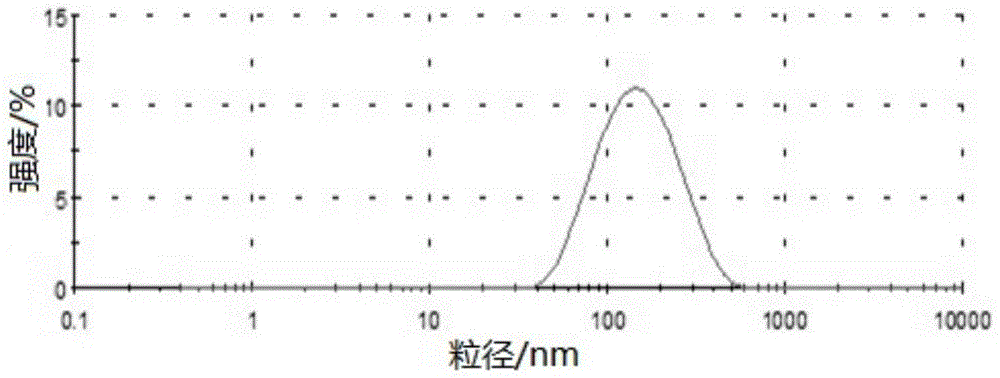

Embodiment 1

[0131] Embodiment 1 Preparation of bezafibrate nanostructured lipid carrier

[0132] Composition formula

[0133] Bezafibrate: 0.05g; solid lipid material glyceryl monostearate: 0.5g; liquid lipid material soybean oil: 10g; fat-soluble emulsifier lecithin: 10g; water-soluble emulsifier Poloxamer 188: 15g; distilled water: 65g.

[0134] The specific preparation method of the above-mentioned bezafibrate nanostructured lipid carrier is as follows:

[0135] Weigh the raw materials according to the weight ratio of the above components, add 10g of fat-soluble emulsifier lecithin and 15g of water-soluble emulsifier Poloxamer-188 into distilled water, heat in a water bath at 65°C and stir evenly to obtain a water phase.

[0136] Heat 0.5g of solid lipid material glyceryl monostearate and 10g of liquid lipid material soybean oil in a 65°C water bath and stir to obtain a liquid oil phase, then add 0.05g of bezafibrate into the liquid oil phase and heat to completely dissolved;

[01...

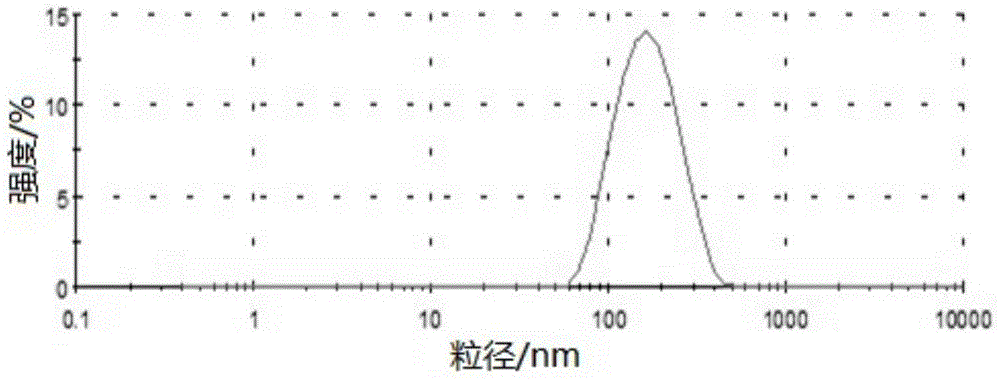

Embodiment 2

[0138] Preparation of Example 2 Bezafibrate Nanostructured Lipid Carrier

[0139] Composition formula

[0140] Bezafibrate: 0.05g; solid lipid material glyceryl monostearate: 0.3g; liquid lipid material soybean oil: 1g; fat-soluble emulsifier lecithin: 1g; water-soluble emulsifier Poloxamer 188: 1.5g; Phosphate buffer solution with a pH of 7.4 and a concentration of 50mmol / L: 46g.

[0141] The specific preparation method of the above-mentioned bezafibrate nanostructured lipid carrier is as follows:

[0142] Weigh the raw materials according to the weight ratio of the above components, add 1g of fat-soluble emulsifier lecithin and 1.5g of water-soluble emulsifier Poloxamer-188 into phosphate buffer, heat in a water bath at 65°C and stir evenly to obtain a water phase .

[0143] Heat 0.3g of solid lipid material glyceryl monostearate and 1g of liquid lipid material soybean oil in a 65°C water bath and stir evenly to obtain a liquid oil phase, then add 0.05g of bezafibrate int...

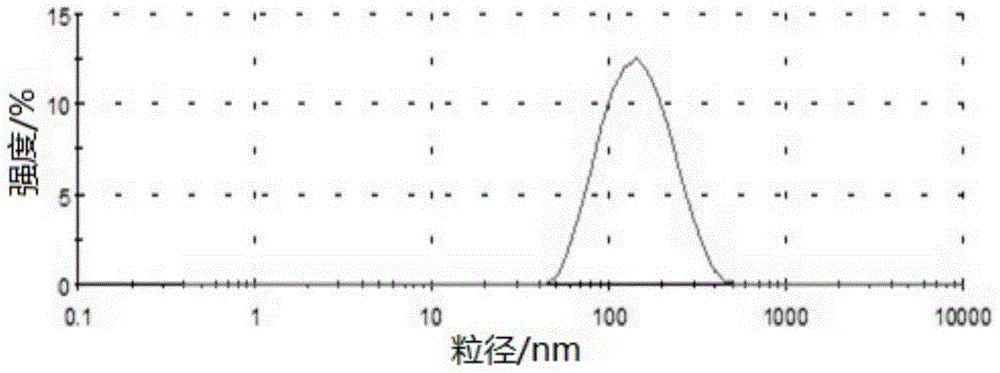

Embodiment 3

[0145] Example 3 Preparation of Bezafibrate Nanostructured Lipid Carrier

[0146] Composition formula

[0147] Bezafibrate: 0.1g; solid lipid material glyceryl monostearate: 1g; liquid lipid material soybean oil: 1g; fat-soluble emulsifier lecithin: 1g; water-soluble emulsifier Poloxamer 188: 3g ; Water for injection: 44g.

[0148] The specific preparation method of the above-mentioned bezafibrate nanostructured lipid carrier is as follows:

[0149] Weigh the raw materials according to the weight ratio of the above components, add 1g of fat-soluble emulsifier lecithin and 3g of water-soluble emulsifier poloxamer-188 into water for injection, heat in a water bath at 65°C and stir evenly to obtain a water phase.

[0150] Heat 1g of the solid lipid material glyceryl monostearate and 1g of the liquid lipid material soybean oil in a 65°C water bath and stir evenly to obtain a liquid oil phase, then add 0.1g of bezafibrate into the liquid oil phase, and heat until completely diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com