Tube forming machine

A forming machine and pipe material technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of inability to complete pipe extrusion, pipe expansion, pipe extraction, and pipe wall processing at one time, so as to achieve simple structure and realize Precise positioning and precision machining of wall thickness, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

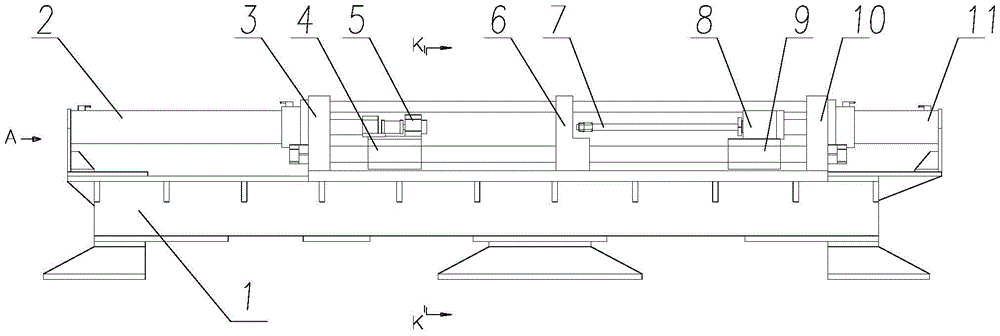

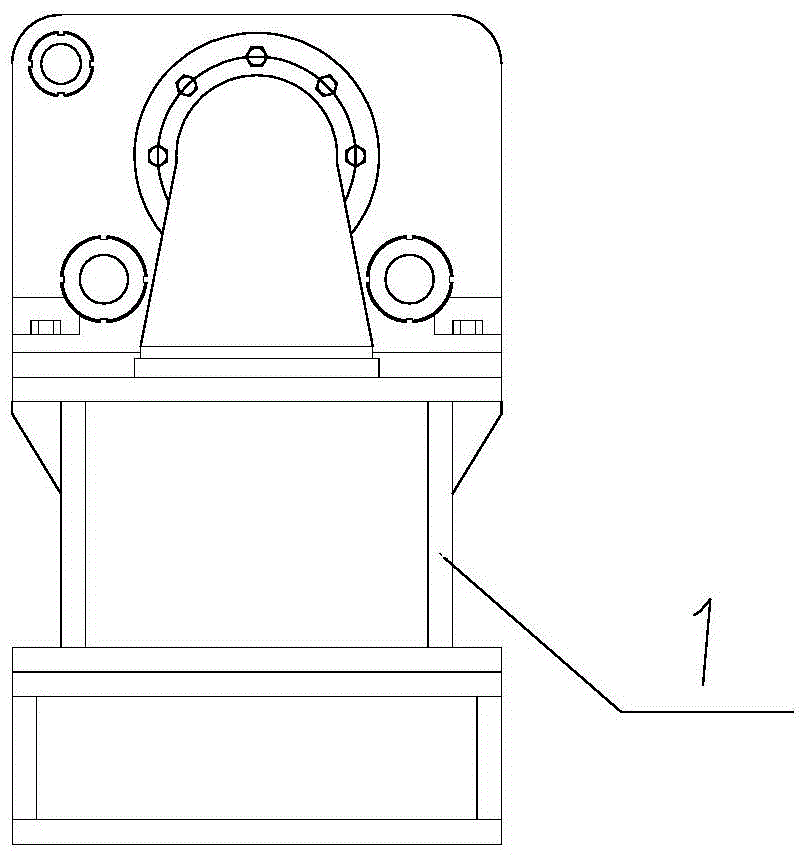

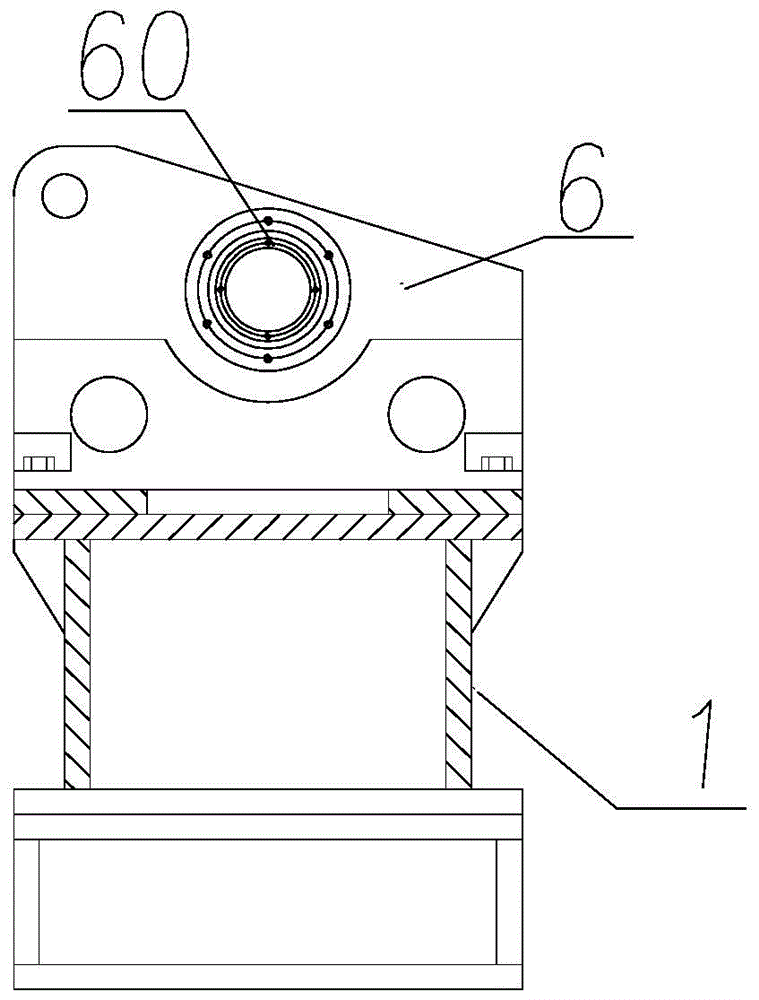

[0023] refer to Figure 1 to Figure 5 , propose an embodiment of a pipe forming machine of the present invention:

[0024] A pipe forming machine includes a base 1 on which a linear slide rail 13 is arranged. One end of the slide rail 13 is provided with a first slide block 4 that can move linearly back and forth on the slide rail 13, and the other end of the slide rail 13 is provided with a second slide block 9 that can move linearly back and forth on the slide rail 13. The base 1 is provided with a first driving device for driving the movement of the first slider 4 and a second driving device for driving the movement of the second slider 9 . The first driving device includes a first oil cylinder base 3 and a first oil cylinder 2 installed on the first oil cylinder base 3 , the movable rod of the first oil cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com