An ionic membrane salt separation concentration crystallization freeze crystallization salt production device and process

A technology of concentrated crystallization and frozen crystallization, which is applied in the direction of chilled water/sewage treatment, alkali metal sulfite/sulfate purification, water/sewage multi-stage treatment, etc. It can solve the problems of difficult reuse, zero discharge, and high operating costs , low recovery rate and other issues, to achieve the effect of less investment cost, low operating cost, and improved purity and recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

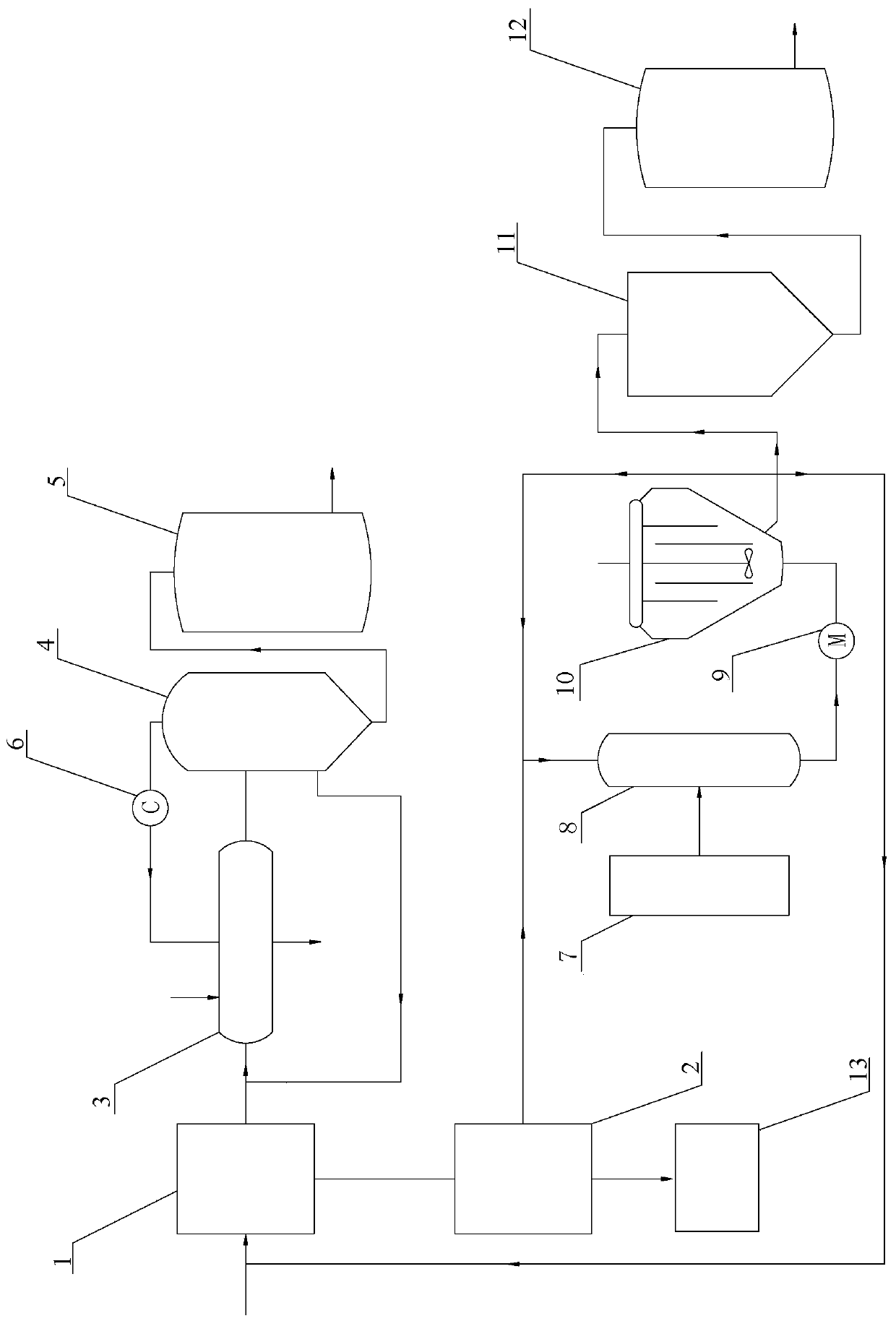

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0026] Such as figure 1 As shown, the ionic membrane salt separation, concentration, crystallization, freezing and crystallization salt making device of the present invention includes: a monovalent ionic membrane salt separation device 1, a special ionic membrane salt concentration device 2, a forced circulation crystallization unit and a continuous freezing crystallization unit (DTB).

[0027] The monovalent ion membrane salt separation device 1 has a water inlet, a concentrated water outlet and a fresh water outlet.

[0028] The forced circulation crystallization unit includes: a heating heat exchange device 3, whose water inlet is connected to the concentrated water outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com