Tung oil polyhydric-alcohol-based nonionic polyurethane capable of being crosslinked later and preparation thereof

A technology of tung oil polyol and polyurethane, which is applied in the field of polymer materials, can solve problems such as non-ionic water-based polyurethane research reports that have not yet been seen, and achieve the effects of facilitating industrial production and popularization and application, improving utilization rate, and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

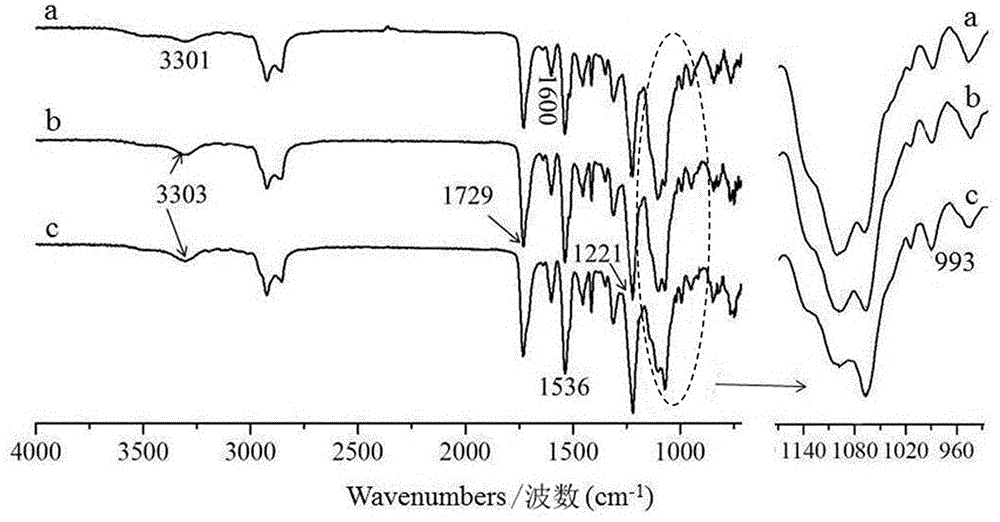

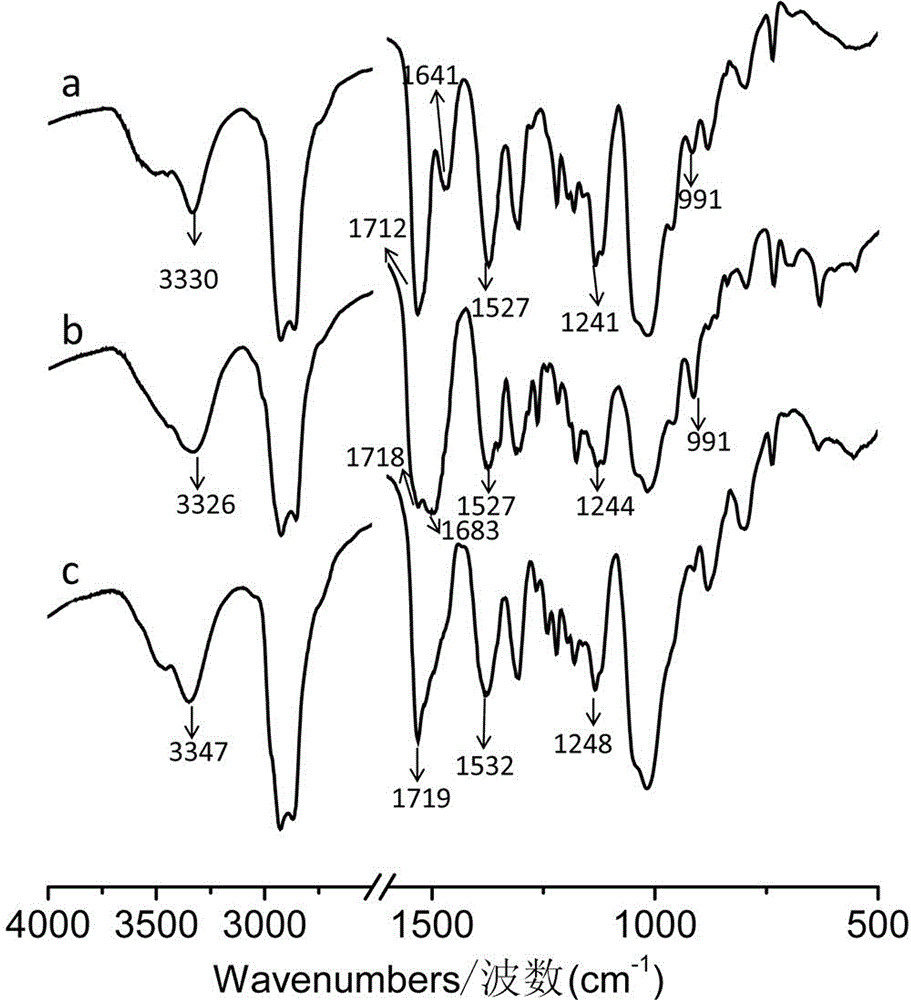

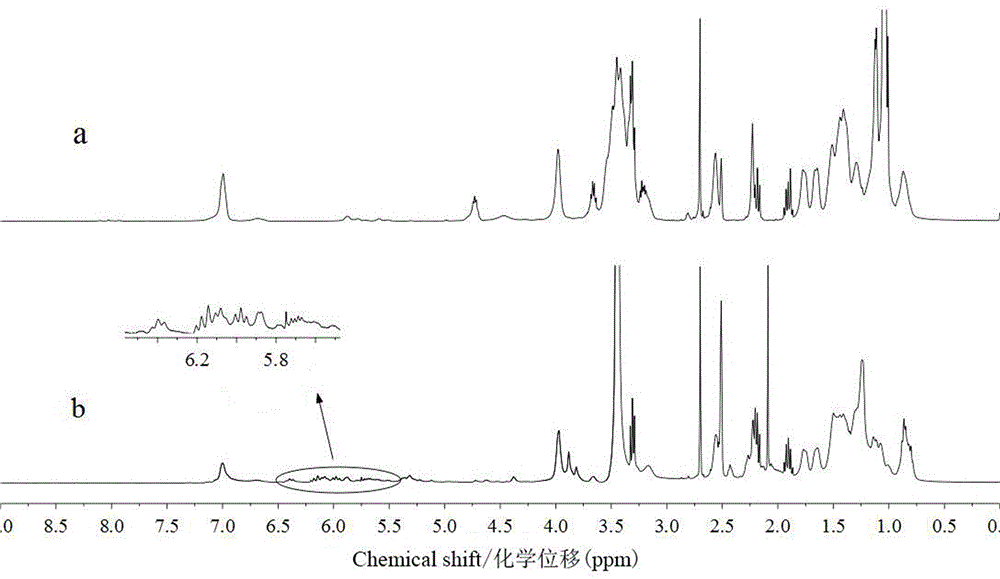

[0029] Embodiment 1: Synthesis of HTO-based nonionic polyurethane by MDI-50

[0030] Add PEG with a molecular weight of 800 (PEG-800) and alcoholysis HTO that have been vacuum dehydrated in advance into a four-necked flask equipped with a nitrogen protection device, add the calculated amount of MDI-50, and heat up to 70°C for about 50 minutes. During the reaction process, a certain amount of NMP is properly added to adjust the viscosity of the system. When the NCO in the reaction system reaches the theoretical value, add distilled water, stir and emulsify at a high speed, and discharge the product to obtain a product with a solid content of 30% (referred to as HTO -NPUD). The resulting emulsion had an HLB of 9.4.

[0031] The molar ratio of the main raw materials: MDI-50: alcoholysis HTO: PEG-800 = 2:1:1

Embodiment 2

[0032] Embodiment 2: Synthesize HTO nonionic polyurethanes of different molar ratios by MDI-50

[0033] Add PEG-800 and alcoholysis HTO, which have been pre-vacuum-dehydrated, into a four-necked flask equipped with a nitrogen protection device, add the calculated amount of MDI-50, and heat up to 70°C for about 40 minutes. During the reaction, a certain amount of NMP is properly added to adjust the viscosity of the system. When the NCO in the reaction system reaches the theoretical value, add distilled water, stir and emulsify at a high speed, and discharge the product to obtain a product with a solid content of 30% (referred to as MDI -NPUD-2). The resulting emulsion had an HLB of 6.8.

[0034] The molar ratio of the main raw materials: MDI-50: alcoholysis HTO: PEG-800 = 3:2:1

Embodiment 3

[0035] Embodiment 3: Synthesize HTO-based nonionic polyurethanes of different molar ratios by MDI-50

[0036] Add PEG-800 and alcoholysis HTO, which have been pre-vacuum-dehydrated, into a four-necked flask equipped with a nitrogen protection device, add the calculated amount of MDI-50, and heat up to 70°C for about 40 minutes. During the reaction, a certain amount of NMP is properly added to adjust the viscosity of the system. When the NCO in the reaction system reaches the theoretical value, add distilled water, stir and emulsify at a high speed, and discharge the product to obtain a product with a solid content of 30% (referred to as MDI -NPUD-3). The resulting emulsion had an HLB of 5.3.

[0037] The molar ratio of the main raw materials: MDI-50: alcoholysis HTO: PEG-800 = 4:3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com