Method for preparing heat-insulation pigment painting paste with high infrared reflectivity for buildings

A thermal insulation coating and infrared reflection technology, which is applied in the direction of reflection/signal coating, pigment slurry, coating, etc., can solve the problems of poor coating appearance, unsatisfactory reflection effect, poor moisture retention and stability of color paste, etc. , to achieve the effect of improving the infrared reflectivity and ensuring the stability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

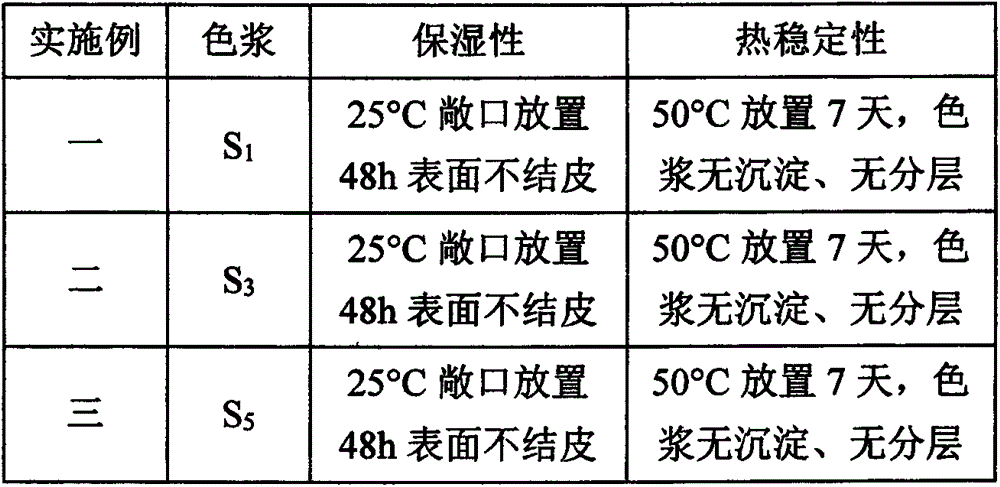

Embodiment 1

[0023] With the pigment yellow VBMo of 50 weight parts, the polyester type polymer dispersant of 5 weight parts, the propylene glycol of 12 weight parts, the ethanolamine of 0.5 weight part, the bentonite thickener of 1.2 weight parts, the deionized water of 31.3 weight parts, Grind for 2 h at a speed of 4200 r / min with a sand mill to obtain a pigment paste.

[0024] Mix aluminum powder and water-soluble phenolic resin in a weight ratio of 1:1, then add the same weight of deionized water to dilute it by one time, and disperse it in a ball mill at 350r / min for 30min to obtain aluminum powder slurry.

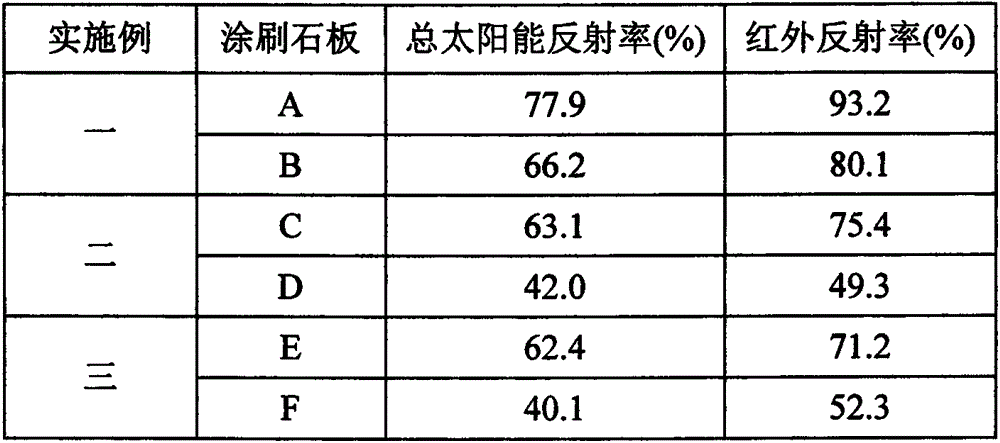

[0025] Add 1 part by weight of aluminum powder paste to 3 parts by weight of pigment yellow VBMo color paste, and stir for 0.5 hours through a high-speed disperser to obtain building heat insulation paint color paste S 1 .

[0026] With 15 parts by weight of building heat insulation paint color paste S 1 And 15 parts by weight of pigment yellow VBMo color paste S without adding ...

Embodiment 2

[0029] With the pigment blue CoCrA1 of 60 weight parts, the polyacrylic acid type macromolecule dispersant of 7 weight parts, the ethylene glycol of 15 weight parts, the diethanolamine of 0.3 weight part, the bentonite thickener of 1 weight part, 16.7 weight parts of Ionized water was ground for 2.5 hours at a speed of 4000r / min by a sand mill to obtain a pigment paste.

[0030] Mix aluminum powder and water-soluble epoxy resin in a weight ratio of 1:1, then add the same weight portion of deionized water to dilute it by one time, and disperse it through a ball mill at 300r / min for 20 minutes to obtain an aluminum powder slurry.

[0031] Add 1 part by weight of aluminum powder paste to 3 parts by weight of pigment paste, and stir for 40 minutes with a high-speed disperser to obtain architectural thermal insulation paint paste S 3 .

[0032] 14 parts by weight of building heat insulation paint color paste S 3 And the pigment blue CoCrA1 color paste S that does not add aluminum...

Embodiment 3

[0035] With the pigment black CuFeMn of 60 weight parts, the polyester type polymer dispersant of 5 weight parts, the propylene glycol of 15 weight parts, the ethanolamine of 0.5 weight part, the bentonite thickener of 1.2 weight parts, the deionized water of 18.3 weight parts, Grind for 2 h at a speed of 4200 r / min with a sand mill to obtain a pigment paste.

[0036] Mix aluminum powder and water-soluble phenolic resin in a weight ratio of 1:1, then add deionized water to dilute it by one time, and disperse it through a ball mill at 350r / min for 30 minutes to obtain aluminum powder slurry.

[0037] Add 1 part by weight of aluminum powder paste to 3 parts by weight of pigment yellow VBMo color paste, and stir for 0.5 hours through a high-speed disperser to obtain building heat insulation paint color paste S 5 .

[0038] With 15 parts by weight of building heat insulation paint color paste S 5 And the pigment black CuFeMn color paste S that does not add aluminum paste of 15 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com