Aluminum plate and strip for power battery case and production method thereof

A technology of power battery and production method, which is applied in the direction of battery pack parts, battery case/cover, battery case/cover material, etc., which can solve the problems of poor deep-drawing and tensile properties, uneven structure, and coarse grains of products, etc. Achieve the effects of increasing elongation, preventing coarsening, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

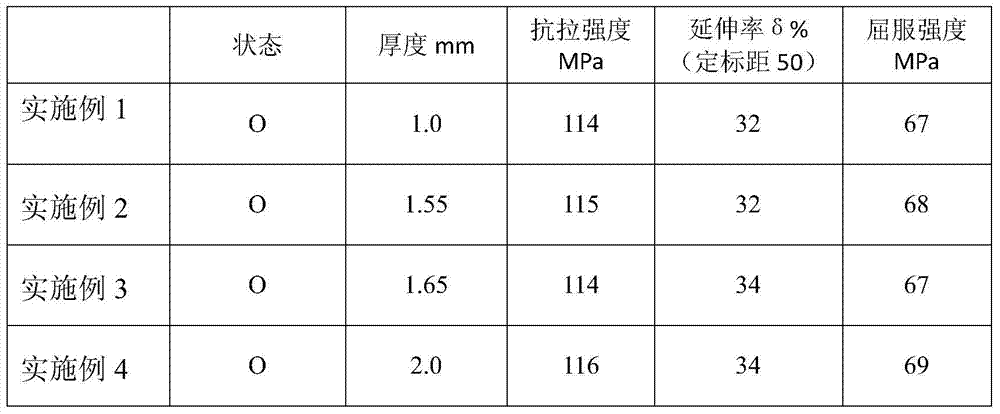

Examples

Embodiment 1

[0033]An aluminum plate and aluminum strip for a power battery case, the mass percentage of its chemical composition is: the composition contains Si0.1%, Fe0.45%, Cu0.09%, Mn1.05%, Zn0.04%, Ti0.04%, The total of impurity elements is ≤0.10%, and the rest is Al.

[0034] A production method of an aluminum plate and an aluminum strip for a power battery case, comprising the following steps:

[0035] (1) Melting: Add 16 tons of pure aluminum ingots and 24 tons of 3-series aluminum alloy waste into the melting furnace, melt for 6 hours to obtain a molten aluminum alloy matrix with a melt temperature of 720-750°C; scrape out the surface of the molten aluminum alloy For scum, take samples to analyze the chemical composition of the aluminum alloy melt matrix, compare the chemical composition requirements of the aluminum plates and strips used for power battery shells, and add aluminum alloy additives to the aluminum alloy melt matrix: 15Kg of titanium additives, 20Kg of iron additives...

Embodiment 2

[0052] An aluminum plate and aluminum strip for a power battery case, the mass percentage of its chemical composition is: the composition contains Si0.15%, Fe0.45%, Cu0.1%, Mn1.1%, Zn0.03%, Ti0.05%, The total of impurity elements is ≤0.10%, and the rest is Al.

[0053] A production method of an aluminum plate and an aluminum strip for a power battery case, comprising the following steps:

[0054] (1) Melting: Add 20 tons of pure aluminum ingots and 20 tons of 3-series aluminum alloy waste into the melting furnace, and melt for 7 hours to obtain a molten aluminum alloy matrix with a melt temperature of 720-750°C; scrape out the surface of the molten aluminum alloy For dross, take samples to analyze the chemical composition of the aluminum alloy melt matrix, compare the chemical composition requirements of the aluminum plates and strips used for power battery shells, and add aluminum alloy additives to the aluminum alloy melt matrix: 21g of titanium additives, 43Kg of iron addit...

Embodiment 3

[0071] An aluminum plate and aluminum strip for a power battery case, the mass percentage of its chemical composition is: the composition contains Si0.13%, Fe0.5%, Cu0.12%, Mn1.1%, Zn0.02%, Ti0.04%, The total of impurity elements is ≤0.10%, and the rest is Al.

[0072] A production method of an aluminum plate and an aluminum strip for a power battery case, comprising the following steps:

[0073] (1) Melting: Add 18 tons of pure aluminum ingots and 22 tons of 3-series aluminum alloy scraps to the melting furnace, and melt for 8 hours to obtain an aluminum alloy melt matrix with a melt temperature of 720-750°C; scrape out the surface of the aluminum alloy melt For scum, take samples to analyze the chemical composition of the aluminum alloy melt matrix, compare the chemical composition requirements of the aluminum plates and strips used for power battery shells, and add aluminum alloy additives to the aluminum alloy melt matrix: 16Kg of titanium additives, 58Kg of iron additives...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com