Method for measuring polymer flooding relative permeability curve

A technology of relative permeability and measurement method, applied in the field of petroleum development, can solve the problems of large error, no polymer flooding, poor reliability of polymer flooding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Measure the basic parameters of the polymer flooding core model, including core length, core diameter, porosity, permeability, irreducible water saturation, residual oil saturation; measure the basic physicochemical parameters of the polymer used, including polymer solution Viscosity, adsorption capacity, residual resistance coefficient, inaccessible pore volume.

[0029] Put the core into the core holder, use a constant temperature box to keep it at a constant temperature (45°C) for 8 hours, set the confining pressure to 3.5Mpa, the back pressure to 300Kpa, and use a molecular weight of 1500╳10 4 The polymer was formulated into an experimental polymer solution with a concentration of 1000mg / L, and the experimental operation was carried out to measure the core and the basic experimental parameters of the polymer. The measurement results are shown in Table 1.

[0030] Table 1 Basic parameters

[0031] parameter name

Embodiment 2

[0032] Example 2: Carry out polymer flooding experiments and record production test data. The specific process is:

[0033] a. the rock core after the end of the experiment in Example 1 is washed, saturated with formation water,

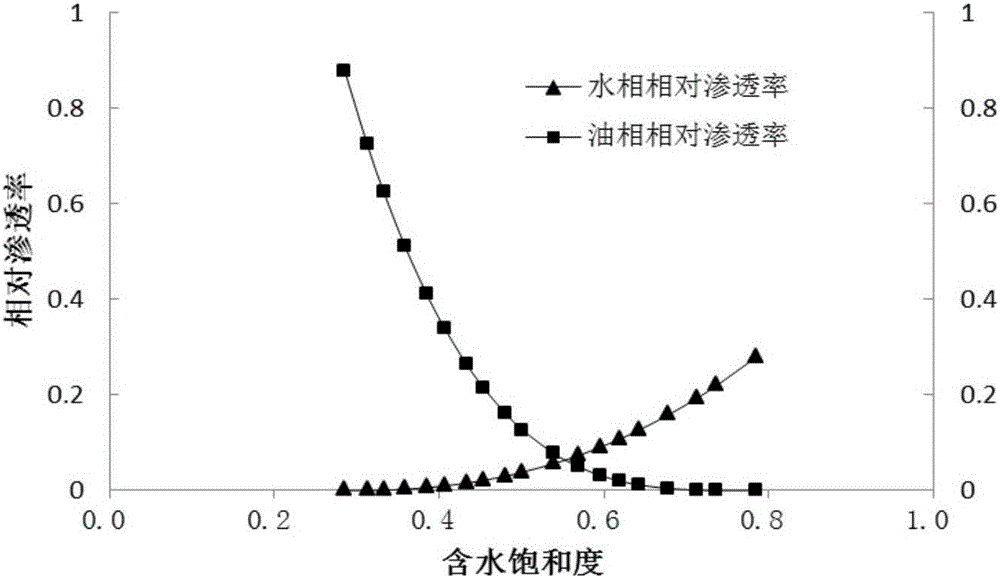

[0034] b. Carry out oil-displacement water in the form of displacement speed from small to large, until the water production no longer increases, and calculate the irreducible water saturation S wc =0.285;

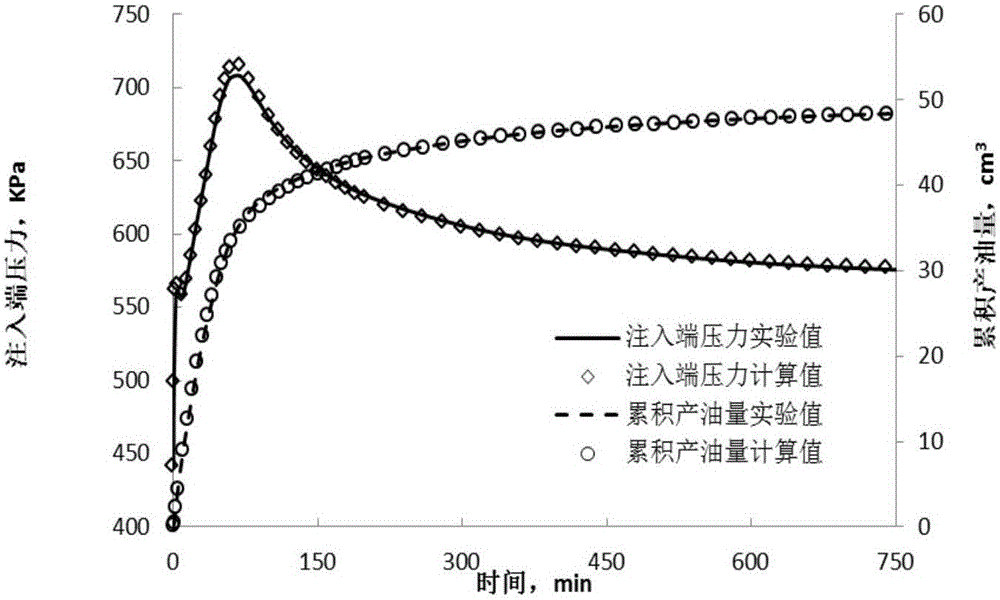

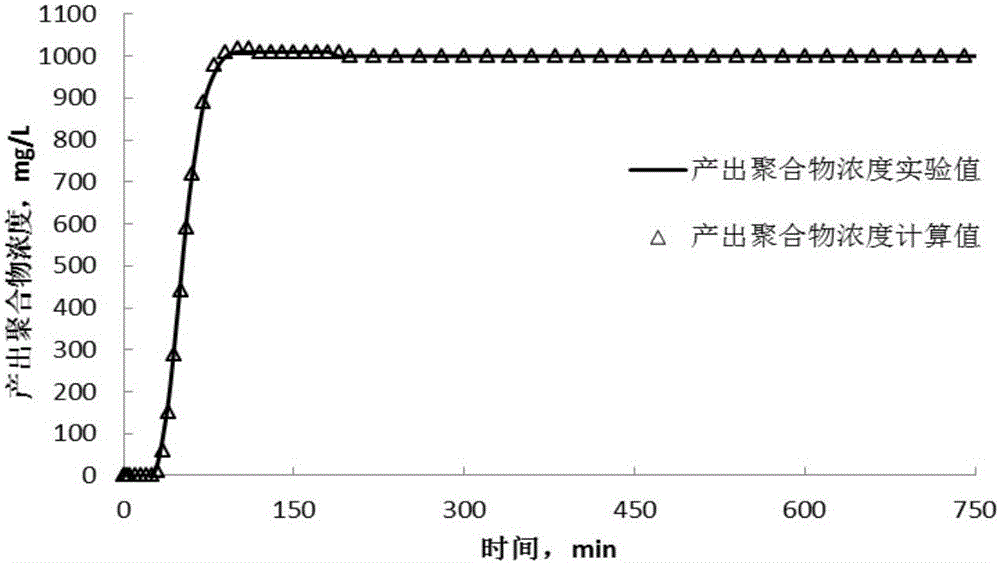

[0035] c. Carry out the polymer flooding process at a constant displacement rate of 1ml / min, record the injection end pressure at different times, the cumulative oil production and the output polymer concentration at the corresponding time, and the displacement process when the oil production no longer increases At the end, calculate the polymer flooding residual oil saturation S orw = 0.215.

Embodiment 3

[0036] Embodiment 3: Using the production dynamic data in Embodiment 2 to carry out automatic history fitting to obtain the optimal polymer flooding relative permeability curve. Specific steps are as follows:

[0037] a. Firstly, normalize the production dynamic data, and take the pressure at the injection end as an example for normalization. Injection end pressure maximum D e,maxp =303.62KPa,D e,min,p =296.33KPa, the tenth pressure data D e,p (10)=300.96KPa, then the normalization process is:

[0038] D p ( 10 ) = 300.96 K P a - 296.33 K P a 303.62 K P a - 296.33 K P a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com