Gear of air compressor

An air compressor and gear technology, applied in belt/chain/gear, mechanical equipment, components with teeth, etc., can solve the problems of gear wear, gear weight, etc., and achieve low noise, high transmission efficiency, and weight reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific figures.

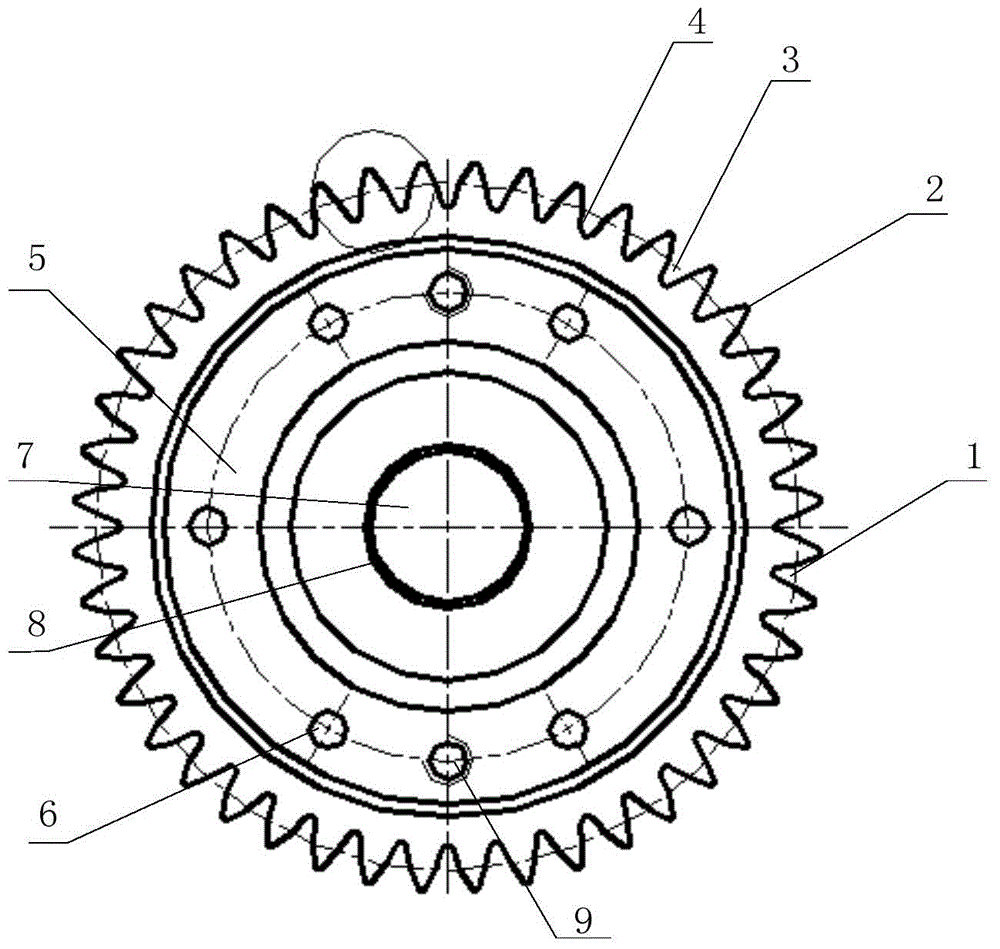

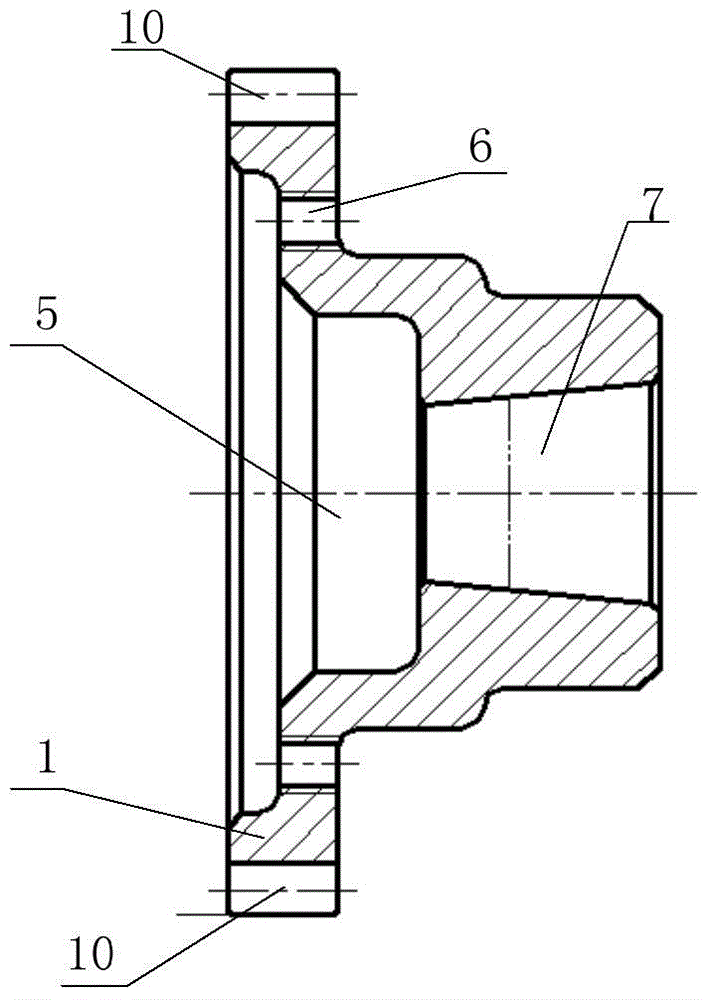

[0019] In specific implementation, an air compressor gear, combined with Figure 1-Figure 4 , including wheel 1, gear teeth 2, tooth slot 3, arc chamfer 4, step hole 5, deweighting hole 6, tapered hole 7, anti-corrosion layer 8, positioning hole 9, deweighting slot 10.

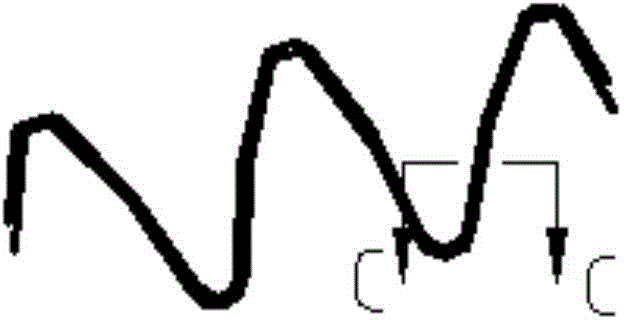

[0020] The air compressor gear includes a rust-proof wheel disc 1, and the wheel disc 1 is made of a carburized steel material. The surface of the wheel disc 1 is subjected to carbonitriding treatment, and a carburized layer is formed on the surface of the wheel disc, and the thickness of the carburized layer is 0.5-0.8 mm. Gear teeth 2 are evenly distributed on the rim of the wheel disc, and there are tooth slots 3 between the two connected gear teeth. The gear teeth are desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com